15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

130 |

Published by VMT at Nov 27 2023

130 |

Published by VMT at Nov 27 2023

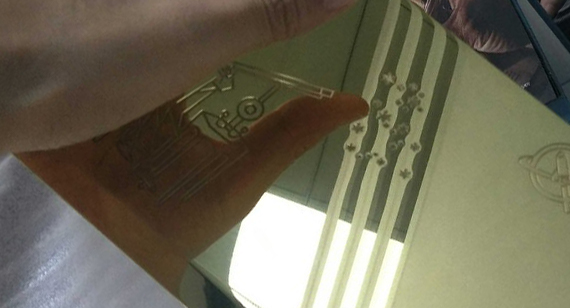

The complete process of stainless steel mirror polishing process from material selection to surface cleaning

Stainless steel mirror polishing process, methods and requirements

This article mainly introduces all aspects of the stainless steel CNC parts mirror polishing process, including material selection, surface pretreatment, mechanical polishing, chemical polishing, electrochemical polishing, grinding and polishing, and surface cleaning.

When selecting stainless steel materials, factors such as hardness, wear resistance, anti-rust performance and processing performance need to be taken into consideration. Commonly used stainless steel mirror polishing materials include 304 stainless steel and 316 stainless steel. Among them, 304 stainless steel has good processing performance and corrosion resistance, and is suitable for various polishing processes. 316 stainless steel has better wear resistance and high temperature performance, and is suitable for high strength and high temperature environments.

2. Surface pretreatment

Surface pretreatment is one of the key steps in mirror polishing, including grinding and cleaning. By polishing, the oxide layer, weld spots and other impurities on the stainless steel surface are removed to make the surface smoother. Cleaning can remove grease, dirt, etc. on the surface to avoid affecting subsequent polishing. At the same time, surface pretreatment can also improve the roughness of the stainless steel surface, which is beneficial to subsequent polishing.

3. Mechanical polishing

Mechanical polishing is the process of grinding and polishing the surface of stainless steel using tools such as abrasives and polishing cloth wheels. The steps include clamping, grinding and polishing. Clamping requires the stainless steel to be fixed on a special fixture to ensure its stability and accuracy. Grinding can use abrasives and cloth wheels of different particle sizes to gradually remove the rough layer on the surface. For polishing, you can use a polishing cloth wheel and polishing fluid to make the surface smoother and smoother.

4.Chemical polishing

Chemical polishing is a process of corrosion treatment on the surface of stainless steel using chemical corrosive agents. The steps include pickling, soaking and chemical gold plating. Pickling can remove the oxide layer and dirt on the surface and improve the cleanliness of the surface. For soaking, you can use appropriate corrosives to make the surface smoother. Chemical gold plating can form a dense gold layer on the surface to improve the anti-rust performance and aesthetics of the surface.

5.Electrochemical polishing

Electrochemical polishing is a process of coating the surface of stainless steel through electrochemical reaction. The steps include electroplating and electrolysis. Electroplating can form a layer of metal coating on the surface to improve the hardness and wear resistance of the surface. Electrolysis can use appropriate electrolyte to make the surface smoother and smoother, improving anti-rust performance and aesthetics.

6. Grinding and polishing

Grinding and polishing are processes that further optimize the surface roughness and gloss of stainless steel. The steps include vibration polishing and rotation polishing. Vibration polishing can use a vibrating grinder to spray abrasive onto the stainless steel surface to remove the remaining rough layer. Rotary polishing can use a rotary polishing machine and a polishing cloth wheel to make the surface smoother and flatter and improve the gloss.

7. Surface cleaning

Surface cleaning is the process of ensuring that the surface of stainless steel is clean and tidy after mirror polishing. The steps include chemical cleaning and ultrasonic cleaning. Chemical cleaning uses appropriate cleaning agents and acidic or alkaline solutions to remove dirt and residue from surfaces. Ultrasonic cleaning can use high-frequency vibration to penetrate the cleaning liquid into the stainless steel surface and remove dirt that is difficult to remove with conventional methods.

Summarize

The stainless steel mirror polishing process requires strict control of material selection, surface pretreatment, mechanical polishing, chemical polishing, electrochemical polishing, grinding and polishing, and surface cleaning. Only when every link is fully guaranteed can we finally obtain high-quality stainless steel mirror CNC machining parts.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!