15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

206 |

Published by VMT at Aug 24 2022

206 |

Published by VMT at Aug 24 2022

In recent years, with the development of high-performance, high-precision CNC machining and the emergence of metal cutting tools with excellent performance, CNC high-gloss machining has made great breakthroughs, and it has become possible to replace grinding with milling (turning), which has become a machining industry successive goals. The principle of CNC high-gloss machining is to use special special tools on precision CNC machining equipment, and cooperate with scientific and reasonable cutting parameters and processes to achieve sparkling surface effects.

At present, CNC high-gloss machining processes (CNC milling, CNC turning) are not well known to technicians in most industrial industries. Actual work shows that they are only truly mastered by a few producers. The main reason is that the demand in the past is not very strong, of course, this is also closely related to cognition. Today we were fortunate enough to find out. Let's take a look at the shell diagram of CNC milling high-gloss processing.

If this is not intuitive enough, you can click this link to jump to tiktok to watch the video: https://www.tiktok.com/@cnc_machining_parts_vmt/video/7131404877531548974?is_from_webapp=1&sender_device=pc&web_id=7104186321606608427

Machine tool

The use of precision CNC machining machines is a prerequisite for high-gloss machining. The machine tool must have good rigidity and precision, such as precision CNC machining and engraving machine. (General speed is: 20000 rpm).

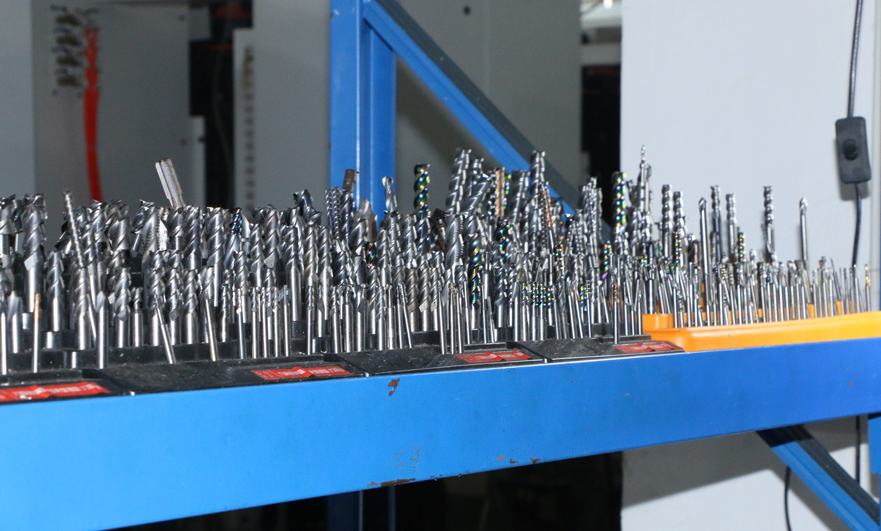

Cutter

The high-gloss effect is achieved thanks to the use of diamond tools. Diamond tools are standard in the CNC high-gloss machining industry.

The cutting edge of a good diamond tool cannot see any notch burrs under a high-power microscope. The cutting edge can withstand long-term cutting without change. The friction coefficient between diamond and non-ferrous metal is very small, the chips are not easy to stick to the blade, and no built-up edge occurs. Therefore, the blade is always kept directly cutting the CNC machined parts during the CNC machining process, and the brightness can be guaranteed.

The high-gloss milling tool has a wider cutting edge, and adopts a small rake angle or a negative rake angle and an edge inclination angle close to zero. When the high-gloss milling is performed, the tool performs high-speed cutting on the one hand, and on the other hand, due to the small rake angle of the tool, Therefore, the cutting edge of the tool forms a scraping and squeezing effect on the machined surface, so that the workpiece surface obtains a high smoothness and produces a hardened layer, which improves the surface hardness and wear resistance of the workpiece.

In addition to the geometry of the workpiece, the geometry of the tool mainly depends on the physical properties of the workpiece material. When CNC machining plastic materials such as copper, aluminum and nickel, the rake angle of the tool is 0o, and the back angle is generally between 5o~10o. The radius of the tool nose arc is usually 0.5~5mm. If the rigidity of the machine tool is high, a larger radius can be used to reduce the surface roughness of the CNC machined parts. give amount. When CNC machining phobic materials such as silicon, germanium, CaF2 and ZnS, the rake angle of the tool is generally selected between -15o~-45o. The optimum rake angle depends not only on the material itself, but also on the stiffness of the machine tool and the clamping system, which is best determined by production tests.

Disc milling cutters are used for high-gloss milling. The diameter of the cutter head should be as large as possible according to the size of the plane to be milled, with better rigidity and good insert positioning accuracy. The size of the cutter head will change the texture and effect of the plane to be milled. The number of inserts can be single or multiple, but it is difficult and time-consuming to adjust the consistency of each insert with multiple inserts. Single-tool milling is better.

Diamond knives look expensive and require a large investment, but natural diamonds are extremely hard and wear-resistant. According to statistics, the life of diamond turning tools is 25 times that of high-speed steel turning tools, and each diamond tool can be reground 6 to 15 times. Therefore, the tool consumption of each CNC machined part is minimal, and stable size and high brightness can be obtained.

CNC machining materials

Materials suitable for high-gloss CNC machining include aluminum, copper, stainless steel, etc. When CNC machining aluminum, its brightness is the brightest, and the wear on the tool is the least; when processing copper, its brightness is relatively bright, and the wear on the tool is second. When CNC machining stainless steel, its brightness is gray and matte, and the wear of the tool is also large.

CNC machining process

The cutting speed of mirror CNC machining and milling is usually around 30m/s. In order to CNC machine a perfect workpiece, the spindle must be dynamically balanced after tool change to minimize the ripples caused by the dynamic imbalance on the surface of CNC machined parts.

The thermal conductivity of diamond tools is good, and the cutting amount is not large, so there is no need to add coolant. On the contrary, adding coolant not only increases the trouble of cleaning after CNC machining, but also the coolant mixed with iron filings often becomes the bane of blade chipping.

The defect of the highlight is that the contour of the CNC machined parts is required to be high and stable, otherwise the highlight will be uneven (large and small edges, etc.).

To obtain safety technical data including all relevant information (such as tools, materials and processing technology, etc.) and make it an optimal combination, it often requires an experience and a running-in process.

CNC machining application

In Guangdong, the trend of metal high-gloss CNC machining is obvious. Aluminum sheet high-gloss is the most widely used in the casing of digital products, and after the high-gloss, it can be oxidized a second time to enhance the wear resistance of the high-gloss area. Stainless steel high-gloss is used in some high-end digital cameras. and mobile phones have also begun to use.

When machining mirror parts in CNC machining factories, we generally summarize the tools and other precautions:

When receiving an order for CNC machining parts from customers, we generally review the drawings in detail. According to the customer's input requirements, combined with the structure of the parts, we especially focus on curved parts, where the R angle and the plane intersect, first of all from the structure of the tool. The advantage of doing design is that there is no knife pattern caused by the knife, which is very important. Of course, the knife path and feed are also very important. Today we mainly talk about knives, and the other is knives. The design of the cutting edge is also very important, because it has a lot to do with the method of chip removal. We must think about smooth chip removal, and do not scratch the surface of CNC machined parts for this reason during CNC machining. Of course, the material of the tool is also very important. Therefore, the tool is generally considered from these points, and the mirror surface of the part can be processed well!

If you have a better one, you can contact us: inquiry@vimetal.com.cn to discuss with us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!