15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

217 |

Published by VMT at Aug 22 2022

217 |

Published by VMT at Aug 22 2022

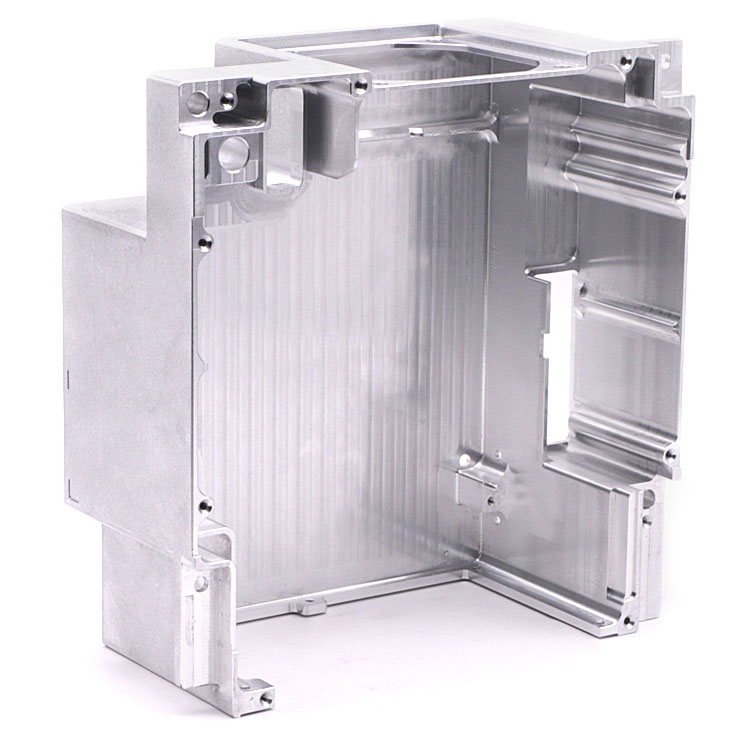

According to personal experience for many years, CNC machining of aluminum alloy cavity, the thinnest side wall height of 10MM can be at least 0.2, 20MM high and the thinnest can be 0.3, 30MM high and the thinnest can be 0.4 The bottom thickness should be determined according to the bottom area How much the thinnest can be done, 300MM can be 0.2, 600MM can be 0.3, 1200 can be 0.4, the thinner the thickness, the longer the CNC machining time and the higher the cost. This factor must be considered in the design of the project , In order to facilitate the product CNC machining cost more competitive advantage!

At the VMT Precision CNC Machining factory, we have the experience required to manufacture high-quality CNC machined parts with extraordinary speed and large-scale CNC machining. Our CNC machining factory in Shenzhen, China has a dedicated team of 8 engineers, 12 inspectors and 90 employees. This small but powerful team is responsible for CNC machining of high-precision parts for companies in China, the United States, Europe and Australia.

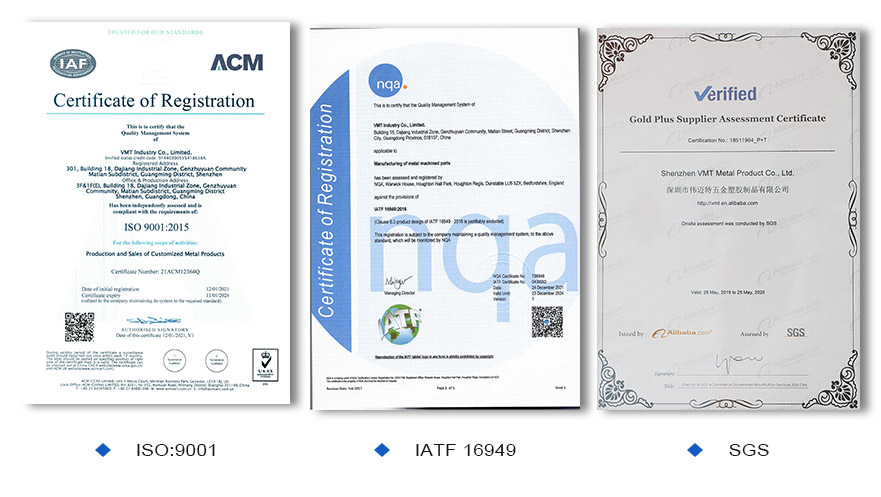

We passed the ISO9001 quality system, IATF16949 certificate and SGS on-site factory audit in 2015. Standardized control and production can CNC process extremely fine aluminum cavities. VMT precision CNC machining 13 years of experience in aluminum cnc machining, professional aluminum cavity cnc machining, aluminum casing CNC machining, aluminum cavity and other aluminum parts processing, high-quality surface treatment one-stop CNC machining service factory, non-standard precision parts according to customers CNC machining is your demand, combined with various CNC machining processes and various difficult surface treatment processes, etc., to provide you with high-quality integrated solutions.

If you have CNC machining parts, you can send the drawings to us for evaluation. After evaluating the drawings, we will give you a reasonable price and a very short delivery time. The quality and service have always been the reputation of VMT. You may try to experience VMTCNC machining. You will be satisfied with the service, and look forward to your custom CNC machining! Our email: inquiry@vimetal.com.cn.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!