15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

597 |

Published by VMT at Jul 04 2022

597 |

Published by VMT at Jul 04 2022

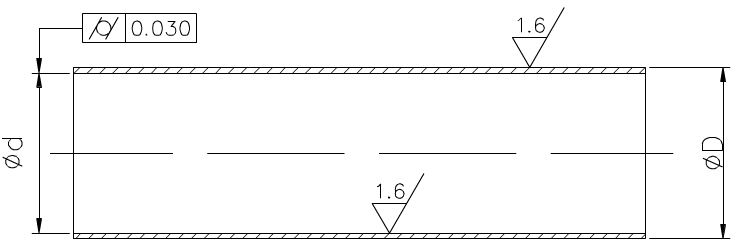

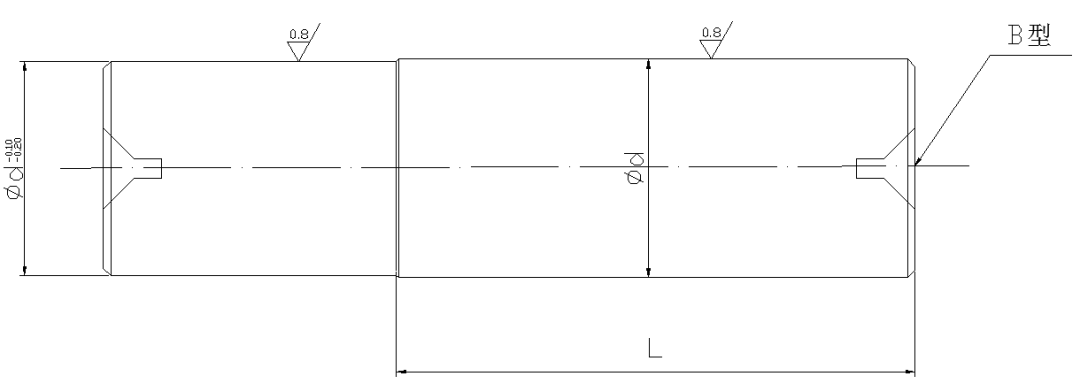

During the cutting process, the thin wall is easily deformed by the cutting force, resulting in an ellipse or a "waist-shaped" phenomenon with a small middle and large ends. In addition, due to the poor heat dissipation during CNC machining, the thin-walled sleeve is easily thermally deformed, and it is not easy to ensure the CNC machining quality of the parts. The parts shown in the figure below are not only inconvenient to clamp, but also difficult to process the processing parts. It is necessary to design a special thin-walled casing and shaft protection.

1. Process Analysis

According to the technical requirements provided by the drawings, the workpiece is CNC machined with seamless steel pipes, and the surface roughness of the inner hole and outer wall is Ra1.6μm, which can be achieved by CNC turning, but the cylindricity of the inner hole is 0.03mm, which is suitable for thin-wall CNC turning. In terms of CNC machining parts, the requirements are higher. In batch CNC turning production, the process route is roughly: blanking - heat treatment - car end face - car outer circle - car inner hole - quality inspection.

The "inner hole machining" process is the key to quality control. It is difficult to guarantee a cylinder of 0.03mm when we cut the inner hole apart from the outer circle and thin-walled casing.

2.The key technology of the hole

The key technology of turning is to solve the problem of rigidity and chip removal of the inner turning tool. To increase the rigidity of the inner hole turning tool, take the following measures:

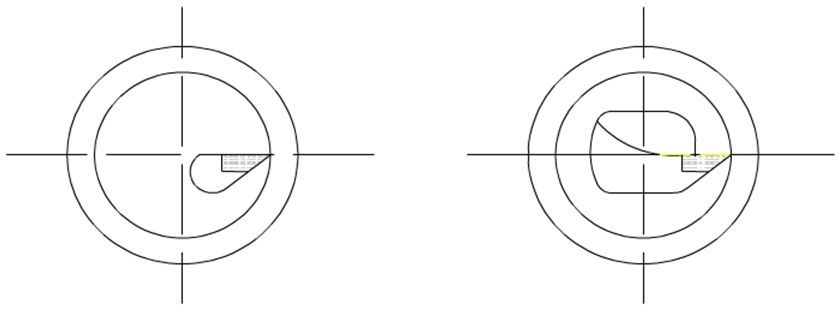

(1) Try to increase the cross-sectional area of the tool handle. Usually, the tip of the inner hole turning tool is located on the top of the tool handle, so that the cross-sectional area of the tool handle is less than 1/4 of the cross-sectional area of the hole, as shown in the left figure below. . If the tool tip of the inner hole turning tool is located on the center line of the tool holder, the cross-sectional area of the tool holder in the hole can be greatly increased, as shown in the right figure below.

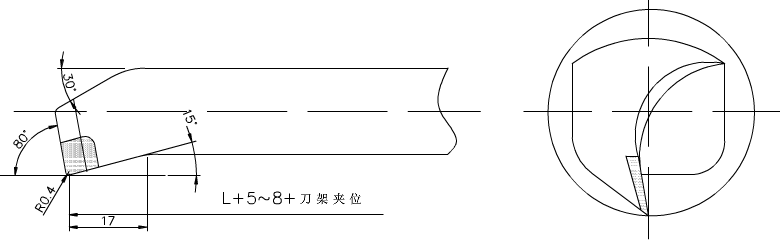

(2) The extension length of the tool shank should be as long as 5-8mm as long as the length of the CNC turning workpiece, so as to increase the rigidity of the tool shank of the turning tool and reduce the vibration during the cutting process.

3.Solve the problem of chip removal

It mainly controls the cutting outflow direction. The rough turning tool requires the chips to flow to the surface to be CNC turned (front chip removal). For this purpose, an inner hole turning tool with a positive edge inclination is used, as shown in the figure below.

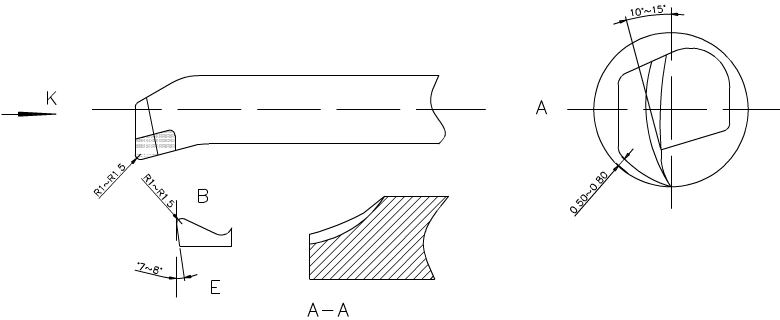

When fine turning, it is required that the chips flow to the centripetal incline for chip removal (hole core chip removal), so when sharpening the tool, pay attention to the grinding direction of the cutting edge, and the method of chip removal by tilting the arc to the front, as shown in the following figure. The knife alloy uses YA6, the current M type, which has better bending strength, wear resistance, impact toughness, and resistance to steel and temperature.

When sharpening, the front angle is ground in a circle with an arc-shaped angle of 10°-15°, and the back angle is 0.5-0.8mm away from the wall according to the CNC turning arc (the bottom line of the tool is along the arc), and the c-cutting edge angle in the k direction is §0.5- 1: The wiper edge is R1-1.5 along the B point of the chip edge, the secondary clearance angle is suitable for grinding to 7°-8°, and the A-A point of the E inner edge is ground into a circle for chip removal.

4.CNC turning processing method

(1) A shaft guard must be done before CNC turning. The main purpose of protecting the shaft: to cover the inner hole of the thin-walled sleeve with the original size, and fix it with the front and rear tops to make the outer circle CNC machined without deformation, and maintain the quality and precision of the outer circle CNC machining. Therefore, the processing of the shaft guard is a key link in the process of CNC turning and processing the thin-walled casing.

45# carbon structural round steel is used for CNC turning and machining of shaft guard blanks; the end face is turned, the B-shaped top holes are opened at both ends, the outer circle is rough turned, and a margin of 1mm is left. After heat treatment, it is quenched and tempered, and then finished with a 0.2mm margin for grinding. The surface of the broken fire is re-heat treated, the hardness is HRC50, and then it is ground by a cylindrical grinder as shown in the figure below.

(2) In order to complete the CNC machining of the workpiece at one time, the blank remains in the clamping position and cutting allowance.

(3) First heat the rough embryo to quench and temper, and the hardness is HRC28-30 (hardness within the range of CNC machining).

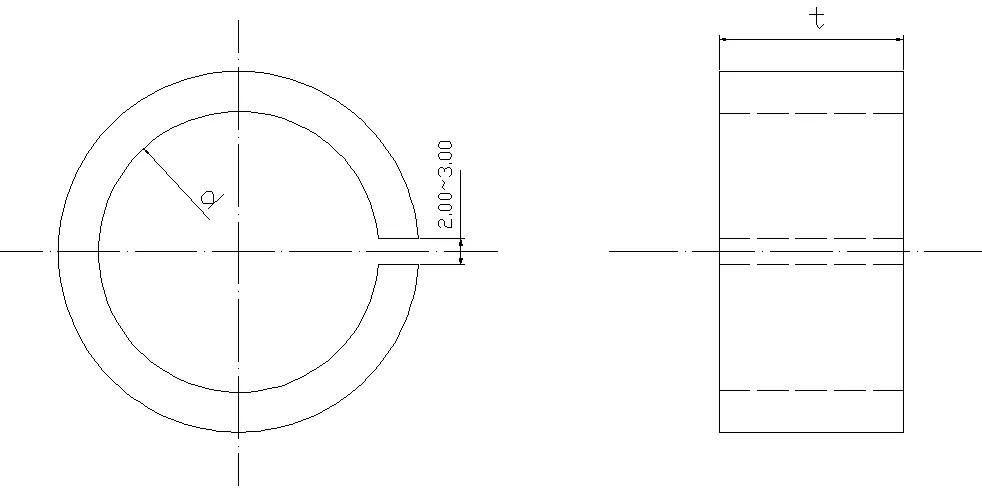

(4) The turning tool adopts C620. First, put the front center into the taper position of the spindle to fix it. In order to prevent the deformation of the workpiece when the thin-walled sleeve is clamped, an open-loop thick sleeve is added, as shown in the figure below.

In order to maintain batch CNC turning production, one end of the outer circle of the thin-walled sleeve is CNC turned into a uniform size d, and the ruler of t is the axial clamping position, and the thin-walled sleeve is pressed to improve the quality of the inner hole of the car. Keep the size. Considering the generation of cutting heat, the expansion size of the workpiece is difficult to grasp. It is necessary to pour sufficient cutting fluid to reduce the thermal deformation of CNC turning parts.

(5) Clamp the workpiece firmly with the self-centering three-jaw chuck, turn the end face, and rough the inner circle of the turning. Leave a margin of 0.1-0.2mm for fine turning, and replace the fine turning tool to CNC process the cutting allowance until the guard shaft meets the requirements of excessive fit and roughness. Remove the inner hole turning tool, insert the guard shaft to the front top, clamp it with the tip of the tailstock according to the length requirements, change the outer turning tool to rough turn the outer circle, and then finish the turning to meet the drawing requirements. After passing the inspection, use a cutting knife to cut it according to the required length. In order to make the incision smooth when the workpiece is disconnected, the blade edge should be obliquely ground to make the end face of the workpiece flat; the small section of the shaft guard is ground to leave a gap for cutting. The shaft guard is to reduce the deformation of the workpiece, prevent vibration, and cut Falling and bruising.

Conclusion

The above method CNC turning thin-walled casing solves the problem of deformation or causing dimensional error and shape error and fails to meet the requirements. Practice has proved that CNC machining has high efficiency, easy operation, and is suitable for CNC machining of long thin-walled parts. The size is easy to grasp, one-time completion, and batch CNC turning production is also more practical.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!