15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

155 |

Published by VMT at Jan 03 2022

155 |

Published by VMT at Jan 03 2022

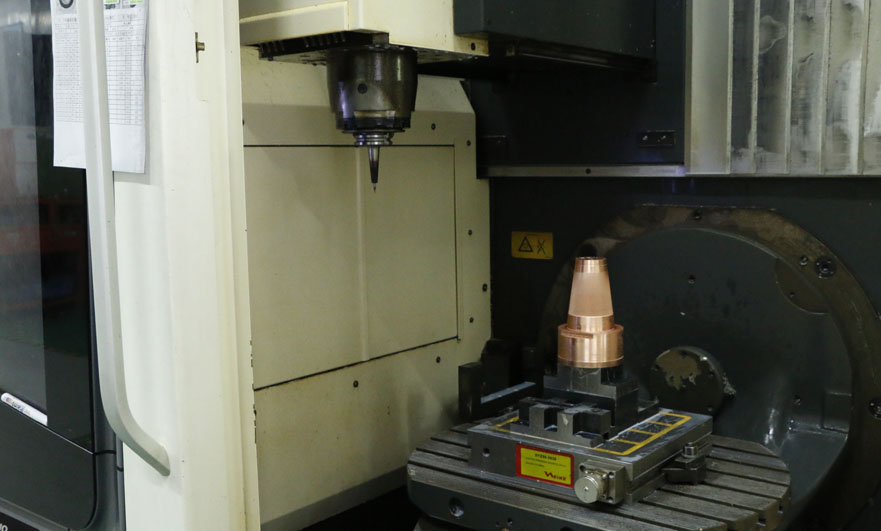

5-axis CNC machining is a method that uses spindle rotation to complete cutting CNC machining. It can make customized CNC machining parts meet the application requirements in terms of shape accuracy, position accuracy, finished part outer surface production and CNC machining. 5-axis CNC machining does not simply combine CNC turning and CNC milling, but uses the spindle motion of 5-axis CNC machining to realize the production and CNC machining of various molds, plates and furniture. Under the current conditions of rapid development of CNC technology, it is a new cutting practice and cutting technology.

Compared with the traditional CNC machining process, the outstanding advantages of 5-axis CNC machining tool preparation include the following aspects:

1) Reduce the manufacturing process chain of customized CNC machining parts and improve production efficiency

Various special tools can be installed. The invention has the advantages of reducing the tool change time of five-axis numerical control processing, improving the numerical control processing efficiency of the product, and completing all or most of the numerical control processing procedures at the same time, greatly shortening the manufacturing time of customized numerical control processing parts. In this way, on the one hand, the production time caused by the loading and replacement of the clamping device is reduced, and the production cycle and waiting time of the fixture are shortened, and the production efficiency of customized CNC machining parts is greatly improved.

2) Reduce the number of clamping times

The reduction in the number of loading times of the clamping device prevents the accumulation of errors caused by the conversion of the positioning reference. At the same time, most of the existing turning-milling composite processing equipment has online inspection functions, which can realize on-site inspection and precision control of key data in the manufacturing process of customized CNC machining parts, thereby improving the accuracy of customized CNC machining parts; high-strength integrated basic design improves The gravity and numerical control processing capabilities of difficult-to-process data; the machine tool is equipped with an active feed device, which realizes the active feed and basically realizes the assembly line operation of a single machine tool.

3) Reduce occupancy and reduce production costs

The 5-axis CNC machining has a compact and elegant appearance design, improved space application measures, making it more convenient for protection and maintenance, and satisfying customers; although the unit price of the turning-milling composite machining equipment is relatively high, due to the reduction of the CNC machining manufacturing process chain, The reduction of equipment required for customized CNC machining parts, as well as the reduction of the number of clamping devices, workshop space and equipment protection costs, can effectively reduce the overall investment in fixed assets, production operations and management costs.

Matters needing attention in 5-axis CNC machining

1. Pay attention to strictly abide by the personnel operating procedures.

Equipment such as 5-axis CNC machining is relatively dangerous during operation, and accidental operators can cause injuries. As long as you follow the operating regulations to avoid personal injury, such as wearing protective equipment, not wearing scarves, gloves, and headscarves as required, women should also pull out their hair and wear hats. Therefore, pay attention to strictly abide by the personnel operating procedures.

2. Pay attention to trial operation before CNC machining parts.

Before starting, adjust the tool compensation, machine zero point and the zero point of customized CNC machining parts, check the equipment protection, insurance, signal and position part, and more importantly, start the trial operation of the machine. Many people may think that it can be opened directly after the inspection is completed. In fact, without trial operation, it is impossible to check the operation status of lubrication, mechanical, electrical, hydraulic, digital display and other systems. Therefore, the operation before trial CNC machining is very important.

3. Pay attention to the inspection of customized CNC machining parts before starting.

The 5-axis CNC machining of reputable communication equipment needs to pay attention to the corresponding preparation work before the equipment is turned on. For example, the inspection of important parts and items requires attention, because many parts, switches, insurances and protections in the equipment may be a hidden danger after the equipment is running. If we can't perform inspections at the beginning, the adverse consequences after starting the machine are unimaginable, so it is very important to do a good job of inspection before starting the machine.

In most cases, general CNC machining machine tools can CNC process many common parts, but high-quality CNC machining parts require 5-axis CNC machining, such as CNC machining equipment. Therefore, in order to produce better CNC machining parts, it is not only necessary to know where the 5-axis CNC machining of the communication equipment is. It is sold, you need to know what to pay attention to when using this 5-axis CNC machining equipment.

The 5-axis CNC machining center is a combination of many different configurations. It can complete a variety of CNC machining process operations and is an intelligent and automated operation. Therefore, when choosing a 5-axis CNC machining center, you also need to understand the service life of the equipment. And it depends on the professional editing control technology used. Only when the technology is stable can the service life of the equipment be increased and the failure rate can be reduced.

The key items to pay attention to when choosing a 5-axis CNC machining center are nothing more than the above three points. The reason to pay special attention to these content is also for the easy-to-use 5-axis CNC machining center and avoid unnecessary cumbersome things.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!