15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

209 |

Published by VMT at Jan 04 2022

209 |

Published by VMT at Jan 04 2022

Screws still play an important role in the machinery industry. To connect the screw to another component, an internal thread is required. The thread can also be cut on the outer surface of the CNC machined part. In this article, we will introduce how to manufacture threads by CNC machining? Thread type, thread design and CNC machining skills, and how to cut thread machines on a lathe, including internal thread cutting and external thread cutting.

Part of the thread can sometimes be eliminated. In the final assembly process, we need to follow a large number of thread design rules in order to manufacture precise threads in CNC machining. In addition, these features are additional consideration and careful work to ensure the final production design of CNC machined parts. A successful thread can make the assembly last for many years.

What are CNC machining parts engineering and manufacturing threads?

The thread is a continuous spiral ridge that forms a uniform cross-section on the inner (nut) or outer (screw or bolt) surface of a cylinder or cone. The thread configuration file is composed of the vertex (the top of the thread), the root (the bottom of the thread), and the flanks (connecting the vertex and the root). The thread pitch is the distance measured parallel to the thread axis, and is the distance between corresponding points on adjacent threads. The pitch diameter is the diameter of the theoretical cylinder. When the theoretical cylinder passes through the thread, the distance between the top of the thread and the root of the thread is equal. In an ideal CNC machined part, these widths are equal to half of the pitch.

Thread type:

According to different classification criteria, there are many types of threads. Machine threads and spacer threads are commonly used fasteners. UNF (fine) thread and UNC (coarse) thread are the standard series in the unified thread system. Let's talk about the internal and external threads of CNC machining parts.

Female thread (female): thread on the inner or concave surface.

External thread (male): the thread on the outside of the cone or cylinder.

Thread pitch

When we talk about threads on bolts and screws, this is not a one-size-fits-all solution. In addition to the metric thread, there are three main imperial metric threads that are part of the unified thread series.

UNC (coarse pitch): 20 threads per inch (TPI)

United Nations Foundation (fine pitch): 28 TPI

UNEF (extra fine pitch): 32 TPI

Please note that adding UNEF thread spacing requires our precision CNC machining service, you can contact us via email or chat. For example, if you want to incorporate a #4-40 screw, you know that the #4 screw has a thread diameter of 0.11 inches. (2.794 mm) There are 40 threads per inch, which means a particularly fine pitch.

Internal thread

We usually use single-sided thread tools to CNC machine internal threads instead of traditional thread taps. You need to leave the navigator diameter on your CAD model and remove the actual thread. We will analyze the vulnerabilities of threads in the following situations:

The hole diameter is within the required thread range.

These holes are CNC milled on one of the three main axes.

These holes are perpendicular to the axis of rotation.

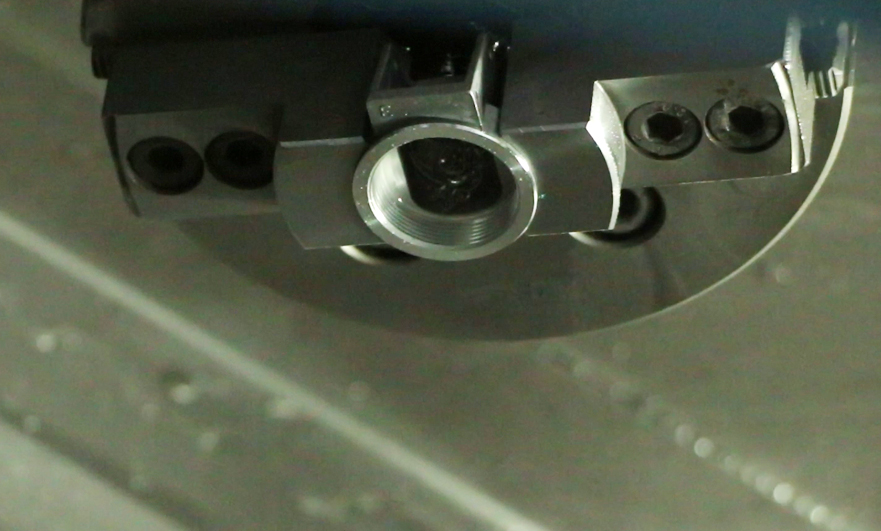

CNC machining of internal threads-how to cut internal threads of CNC machining parts?

For CNC machining of an internal thread, you need a twist drill, 90° countersunk, internal hand or machine tap, adjustable tap wrench (hand) or hand drill (machine), and safety goggles. Before threading, you need to know which faucet to choose and what diameter hole you need. The internal faucet is specified based on the nominal size. The diameter of the twist drill used for tapping or the calculation formula of the twist drill is: core hole diameter = tap diameter-thread pitch.

1. Use a punch to center, and then use a twist drill to drill the core hole.

2. Use a 90-degree anti-sinking groove to sink the anti-sink into the core hole and make a chamfer.

3. Put the tap into the wrench and put it into the core hole to cut off the thread.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!