15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

101 |

Published by VMT at Sep 01 2021

101 |

Published by VMT at Sep 01 2021

People who are familiar with CNC machining are no strangers to 5-axis CNC machining. It can be said that 5-axis CNC machining is very important in the field of precision CNC machining. For machining beginners, the fixture may be one of the tasks that will be challenged in the setup process.

Although there are many different types of CNC machining and manufacturing machines that have available equipment fixtures, such as: centering vise, dovetail fixture, serrated jaws, positioning pins or specially designed fixtures, etc.

Why Choose 5-axis CNC Machining?

In the history of CNC machining development, there was a period of time when people chose to use manual milling machines. About two decades ago, people began to switch from manual milling machines to automated CNC machining.

The updated iteration of CNC finally led to the emergence of 5-axis CNC machining and occupy effective competition. Today, as many as 60% of the parts produced in CNC machining workshops require 5-axis CNC machining.

There are certain differences between 5-axis CNC machining and 3-axis CNC machining, which reduces the setup time, improves the accuracy, and has advantages in expanding the workshop's ability to work in the future.

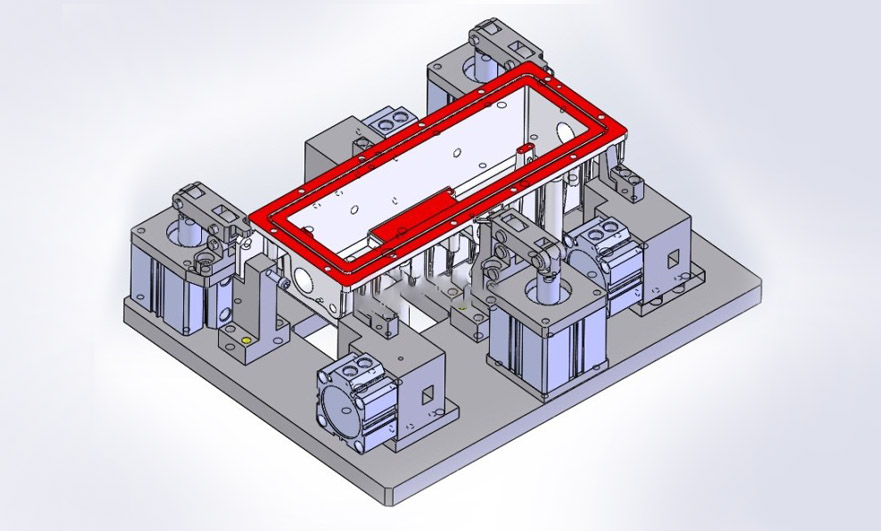

What Fixtures are Available for 5-Axis CNC Machining?

Centering Vise

Centering vise, also called centering vise, synchronous clamp. Its 2 jaws move back and forth synchronously to realize the center clamping of 5-axis CNC machining parts, and the clamping accuracy is high. The jaws are customized according to the contours of the 5-axis CNC machining parts, not only for 5-axis CNC machining The parts can be clamped by external clamps and can be tensioned by internal bracing, which can process CNC machining parts with different contours. The operation is simple and fast, and the cost is greatly saved.

Dovetail Fixture

Dovetail fixture is also a very popular way to clamp 5-axis CNC machining parts for processing. In this fixing method, a special dovetail milling cutter is used to cut the dovetail corners on the bottom side of the part. The fixture body has a set of matching inclined dovetail jaws for receiving 5-axis CNC machining parts, and clamping force is applied to fix the parts through hexagon socket screws.

Positioning Pin

The function of the positioning pin is to limit the degree of freedom of movement of the object. This degree of freedom means that the object has six degrees of freedom in space, the linear movement of the three axes of X, Y, and Z and the rotational movement around X, Y, and Z.

In addition to the fixtures mentioned above, there are also serrated jaws and some custom fixtures. It should be noted here that a common misunderstanding of 5-axis CNC machining is that only one part can be fixed at a time. However, through some originality and proper planning in actual operation, it is very possible to fix multiple parts at a time.

In Conclusion

5-axis CNC machining is a multi-faceted machining process. It is feasible to design and build your own DIY fixture to achieve your goals through a little creativity and some modern fixture clamping hardware.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!