15 years one-stop China custom CNC machining parts factory

297 |

Published by VMT at Sep 01 2021

297 |

Published by VMT at Sep 01 2021

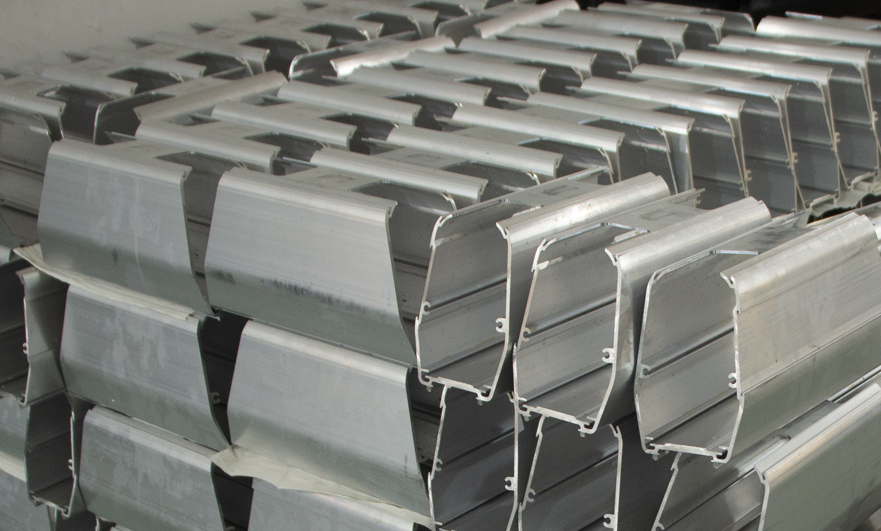

Aluminum profiles are mainly based on 6 series, and 6 series aluminum profiles have a common feature. The mechanical properties and corrosion resistance of aluminum alloys are medium. Therefore, aluminum profiles are widely used in construction, industry, transportation, and other fields. It is also the most common material.

However, because of the characteristics of aluminum profiles, CNC machining is required for installation and special purposes. So what are the issues that need to be paid attention to in CNC machining of aluminum profiles? This article mainly talks about the problems and solutions encountered in the CNC machining of aluminum profiles. If you are interested in CNC aluminum profile processing problems, you must read the following article.

What Problems will be Encountered in the Machining of Aluminum Profiles?

We know that the hardness of aluminum profiles is lower than that of other metals. Therefore, the deformation of aluminum profiles is the most important issue, and most of the issues we discuss are focused on paying attention to the deformation. Therefore, the issues that need to be paid attention to for CNC machining of aluminum profiles are clamping, tool selection, cutting and so on.

Common Problems of Aluminum Profile CNC Machining and Clamping

What problems will be encountered in the CNC machining of aluminum profile fashion clips? Because of the characteristics of the aluminum profile, it is necessary to pay attention to whether the aluminum profile will be scratched or deformed when the aluminum profile is clamped. We should pay attention to the choice of fixtures during CNC machining.

Combination Fixture

Modular clamps are also called "building block clamps". Modular clamps have the advantages of high positioning accuracy, large clamping flexibility, repeated use, energy-saving and material-saving manufacturing, and low cost. Therefore, small batch processing, processing complex-shaped CNC machining parts can be given priority to modular fixtures.

It is composed of components of machine tool fixtures with standardized designs, different functions, and different specifications and sizes. Using a method similar to "building blocks", different types of machine tool fixtures can be quickly assembled.

The modular fixture saves the time of designing and manufacturing special fixtures, can greatly shorten the preparation time before CNC machining and production, and is very suitable for the production cycle of small batch CNC machining parts, and improves the efficiency of production.

Pneumatic Fixture

It has many advantages such as compact structure, multi-station clamping, high-speed milling and automatic control. VMT has developed many types of pneumatic fixtures for various aluminum CNC machining parts, such as automatic moving and quick-adjusting fixtures and multi-station fixtures, which meet the different processing needs of most customers. Because it is easy to use and can be adjusted quickly, it is suitable for large quantities of CNC machining parts, which makes the aluminum profile CNC machining center operate faster.

It uses air pressure as the power source and is composed of positioning elements, clamping devices, clamps and other original components. Become. It is a special fixture for positioning, supporting and clamping of CNC machining parts by controlling the action of pneumatic components through PLC programming. Pneumatic fixtures can accurately and quickly determine the positions of CNC machining parts, machine tools, and cutting tools.

The position accuracy of the CNC machined parts is guaranteed by the fixture to ensure the accuracy of the CNC machined parts. The positioning process is fast, which greatly saves the time of loading and unloading, and realizes the function of automatic clamping.

Electromagnet Fixture

An electromagnet is a device that can pass current to generate magnetic force. It is a non-permanent magnet, and its magnetism can be easily activated or eliminated. Combining the electromagnet with the fixture can be made into an electromagnet fixture. After the electromagnet is connected to the current, the attraction of the magnet can be turned on or off through the M code command of the CNC machine.

This type of fixture is generally suitable for mass production CNC For machining parts, when other conventional fixtures cannot be used to clamp CNC machined parts, or the clamping efficiency is low, the manufacturing cost is relatively high.

Vise Fixture

The vise clamp is also called the universal clamp, which has the advantages of strong versatility, simple structure, and convenient adjustment. It can be well adapted to the transformation of processing procedures and processing objects. Its structure has been finalized, size, and specifications are serialized. Through clamping on the CNC machining table, the CNC machining parts can be quickly positioned, and it is suitable for clamping precision machining parts.

Because of the material problem of aluminum profiles, we can consider using pneumatic clamps when clamping. When clamping, pay attention to the position of the clamping, the remaining wall thickness, and the starting direction of processing.

Frequently Asked Questions about Tool Selection for CNC Machining of Aluminum Profiles

The choice of CNC machining tools is very important. The general tool materials are roughly divided into high-speed steel, tungsten steel, tungsten steel coating, ceramic knives, etc. The number of blades in common use ranges from 2 blades, 3 blades, 4 blades, and 5-6 blades. When choosing a tool, we should consider the following issues:

1. The tool is one of the important factors in the machining process

The aluminum profile processing center can only create profits for the enterprise when it is working, rather than shutting down. So when a tool stops working, it indicates that there is a problem in the production process, which consumes the cost of CNC machining. The machining tools used for different parts and shapes of CNC machining parts are also different. Therefore, in machining, it is necessary to understand the application of different CNC machining tools and choose the right tool.

2. To match the machine tool

Generally, the left-hand tool is suitable for clockwise (CW spindle direction) machining, and the right-hand tool is suitable for counterclockwise (CCW) machining (the tool is facing upwards, and the tip of the tool is on the left is a left offset tool, otherwise it is a right offset tool, so The choice of tool is very important.

Most of the current aluminum profile machining centers are left-handed and left-handed, so left-handed tools are generally used.

3. Match with the processed material

Carbon steel material is a relatively common material to be processed in CNC machining, so most CNC machining tools are based on optimized carbon steel machining design. Choose the tool according to the material to be processed, the processing effect is also better. Numerical processing parts and tool manufacturers provide a series of cutter bodies and matching blades for processing non-ferrous materials such as high-temperature alloys, titanium alloys, aluminum, composite materials, plastics and pure metals.

4. Choose standard tool or non-standard special tool.

With the popularity of aluminum profile machining centers, many people think that CNC machining shapes can be realized through programming without relying on tools. Therefore, non-standard special tools are no longer needed.

5. Programming

Faced with the performance of different tools, CNC machining parts and aluminum profile machining centers, choose a better tool path and find the most suitable tool usage method. The characteristics of the tool should be considered, such as the ramping milling angle, the machining rotation direction, the machining feed, and the cutting speed. According to each CNC machining tool, select the corresponding programming technology to shorten the processing cycle, improve the chip, reduce the cutting force to save the processing time, and improve the production efficiency.

6. Tool price

The price of cutting tools for CNC machining parts is also very important, and some CNC machining manufacturers like to choose cheap cutting tools. But I don’t know that cheap tools increase production costs. Although good knives are expensive, the true value of knives is reflected in improving production efficiency for enterprises.

In general aluminum profile processing, we use high-speed steel and tungsten steel knives to process. After confirming the tool, we must pay attention to the problems of the tool when cutting. Because the aluminum profile has low hardness, large plasticity, and serious cutting deformation, so we are cutting The cutting tool must be optimized, and at the same time, a large chip space must be provided to ensure the normal operation of the tool and reduce the tool teeth.

Cutting Problem of Aluminum Profile

The cutting speed should be controlled well. The cutting speed of CNC machining of aluminum profiles should not be too fast. Because the hardness of aluminum profiles is low, too fast cutting speeds will cause many problems. Before cutting aluminum profiles, we must use special aluminum alloy cutting. Emulsifier plays a role in cooling, lubricating and cleaning in CNC machining.

In general, we need to pay attention to these points when CNC machining aluminum materials:

1. Low hardness, easy to stick to the knife at high temperature.

2. Aluminium is not resistant to high temperature, and it is easy to crack at high temperature.

3. Related to machining cutting fluid: oily cutting fluid, good lubricating performance, water-soluble cutting fluid, good cooling performance.

4. When processing pure aluminum, we should choose the special end mill for aluminum CNC machining parts, with a sharp edge, a positive rake angle, a large chip flute, and a helix angle of 45 degrees or 55 degrees.

5. The materials of the processed parts and CNC tools must have a greater affinity.

6. Use tools with rough rake faces to process low-hardness materials.

Summarize

As long as you pay attention to the above points, there will be no major problems in the CNC machining of aluminum profiles. The most important thing is practice makes perfect. Many things are accumulated experience. Learn more and explore, I believe everyone can avoid the above common problems of aluminum CNC machining parts.