15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

130 |

Published by VMT at Aug 19 2021

130 |

Published by VMT at Aug 19 2021

Commonly used CNC machining materials are used in the electronics industry, and the small and complex parts that constitute larger electronic components have ultra-high precision to make them suitable, or suitable for large-scale computer aluminum shell parts. In addition, the strict tolerance provided by the machining center means that the processed parts have to go through a minimum of processing steps to achieve the final use effect.

The Status Quo of CNC Machining in the Electronics Industry

CNC machining is currently a widely used manufacturing process for metal and plastic parts. It is known for its accuracy, repeatability and ability to produce durable parts by extruding blocks of material.

It can also produce precision metal parts in a short time because it does not require tools, but can produce higher quality parts than other short-cycle technologies such as 3D printing.

For these reasons, CNC machining is very suitable for the prototyping and production of electronic device components, from simple handheld devices to expensive industrial equipment.

Large and small parts, simple and complex parts can be processed by CNC, and CNC processing is widely used.

CNC Machining Electronic Metal Connectors and Sockets

Many electronic devices need to be used in conjunction with other electronic devices, such as the HDMI cable, VGA cable, and DVI cable of the host, or the USB of the keyboard and mouse.

All this requires electronic metal connectors and sockets, which help to connect devices. However, the processing requirements for these parts are very strict. Therefore, such small metal parts need to strictly control the tolerance, otherwise it will cause the connection between the devices to fail.

The advantages of choosing CNC machining:

1. Machinable high-conductivity metal parts

2. Strictly control tolerances

3. Rapid prototyping

4. Can be used for disposable equipment or short-term production and processing

CNC Machined Radiator

As for the material of the heat sink, the thermal conductivity of each material is different, and the thermal conductivity is arranged from high to low. They are silver, copper, aluminum and steel. However, using silver as a heat sink is too costly, so the best solution is to use copper. Although aluminum is much cheaper, it is obviously inferior to copper in thermal conductivity (only about 50% of copper).

Most machined radiators are made of aluminum or copper alloys, but other possible raw materials include stainless steel plates and Inconel. CNC production and processing of radiators is generally conducive to short-term production or rapid prototyping of electronic equipment.

CNC machining advantages

1. A variety of material options

2. Short cycle

3. The CNC machining functions and solutions can be flexibly adjusted

4. Strictly control tolerances

5. Ideal for prototyping and verification

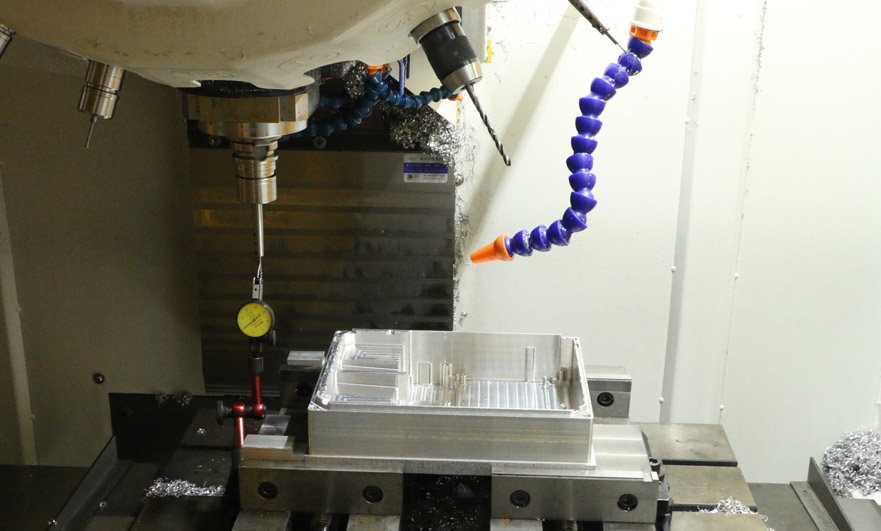

CNC Machining of Electronic Equipment Case housing

Compared with the conductivity and accuracy of CNC equipment PCB manufacturing, the accuracy requirements of the equipment shell are relatively low. The material of the housing is generally made of metal or plastic.

Such enclosures can also be manufactured by aluminum die-casting or other processing techniques, but CNC machining has the advantages of high precision and small dimensional tolerances, and is very important for the surface appearance of electronic equipment enclosures that are in high demand on the market.

In order to make products more beautiful and practical, many CNC machining manufacturers use forming processes to manufacture parts, but other CNC machining manufacturers prefer CNC to process complex parts, discuss design solutions, and choose suitable surface treatments for customers.

Advantages of CNC machining housing:

1. Turned from aluminum and other raw materials, with high compressive strength

2.15 kinds of surface treatment

3. Can be hand-carved

4. Die-casting and rapid prototyping

Summary

CNC machining is an option that can quickly process and shape electronic equipment parts. The general advantages are fast molding time, good safety performance, a variety of material selection and surface treatment, and so on.

VMT can help you understand the way of CNC machining in the electronics industry, and can give you a reasonable solution from processing materials to post-oxidation. Our professional CNC machining manufacturer team has deep industry knowledge and experience, and we will be committed to making your next project a success. If you need customized electronic accessories and shell machining, contact us immediately, we will reply you as soon as possible.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!