15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

97 |

Published by VMT at Aug 26 2021

97 |

Published by VMT at Aug 26 2021

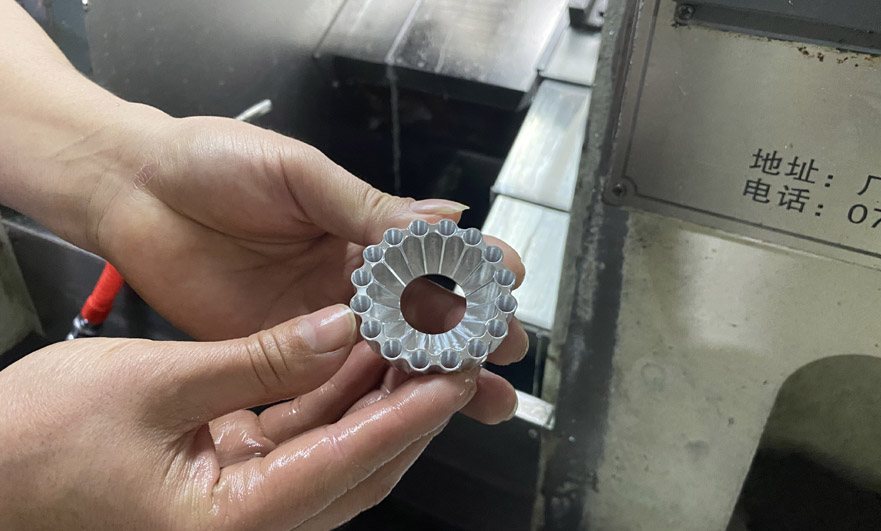

Metal parts of Medical Equipments refer to instruments, equipment, appliances, in vitro diagnostic reagents and calibrators, materials and other similar or related items used directly or indirectly on the human body, including required computer software, metal parts, and optical instruments. These precision metal parts have higher processing requirements and are more complex and difficult to process.

The surface treatment of metal parts is indispensable for the processing of Medical Equipments. Processes such as decorative electroplating can enhance the corrosion resistance of the product and prolong the service life of the product. Different materials are used in the processing of different metal parts, which require high material accuracy and corrosion resistance. In order to understand faster, VMT will lead you to understand the production and application of CNC machined metal parts in the medical industry.

What is Medical Equipment Parts Processing?

Medical machinery metal parts machining is a process of changing the precision, shape, size or performance of the workpiece through CNC machinery.

Classification of Medical Equipments

The first category refers to ensuring the safety and effectiveness of metal parts of Medical Equipments through daily management.

The second category refers to the metal parts of Medical Equipments whose safety and effectiveness should be controlled.

The third category refers to Medical Equipment parts implanted in the human body; used to support and maintain life; they are potentially dangerous to the human body, and their safety and effectiveness must be strictly controlled.

How to Produce High-Quality and Low-Error Precision Medical Equipment Metal Parts?

1. Shell machining

The CNC machining center can complete 60-95% of the processing of ordinary machine tools. It has the characteristics of high processing efficiency and automatic tool change. As long as the control plan, production process flow, and the correct use of special fixtures and tools.

2. Complex Surface Parts

Using ordinary machine tools or precision parts to process parts with complex surface contours is difficult to achieve high precision and difficult to detect. However, these complex parts can be processed using a multi-axis linkage CNC machining center, combined with automatic programming technology and special tools.

3. Special-Shaped Parts

Most special-shaped parts require mixed processing of multi-station points, lines, and surfaces (such as brackets, bases, etc.). The CNC machining center is very fast in processing these complex parts.

4. New Product Prototype Manufacturing

The CNC machining center has a wide processing range, strong adaptability and flexibility. Inputting a new program can realize precision metal parts processing, sometimes by modifying the program segment or special instructions for processing. Use the "Zoom" function command to process parts with the same shape and different sizes. It improves the processing efficiency, reduces the cost and shortens the production cycle for the production of prototypes, small batches, and complex parts.

Why do the Metal Parts of Medical Equipments need Surface Treatment?

The material of the metal parts of medical equipment is damaged during long-term use. In order to enhance the corrosion resistance of the product, metal pretreatment and decorative electroplating are often used to extend the service life of the product.

The application of metal surface treatment such as: phosphating treatment before spraying, surface passivation, pickling to remove the surface oxide layer, aluminum anodizing, baking paint, etc.

Summarize

Medical equipment high-precision metal machining parts, and the processing requirements and difficulty are higher than those in some industries. The quality of metal parts is the key to the development of the mahcining industry. Therefore, improving the precision and quality of precision machining parts is what every precision machining factory has been doing.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!