15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

147 |

Published by VMT at Jan 13 2022

147 |

Published by VMT at Jan 13 2022

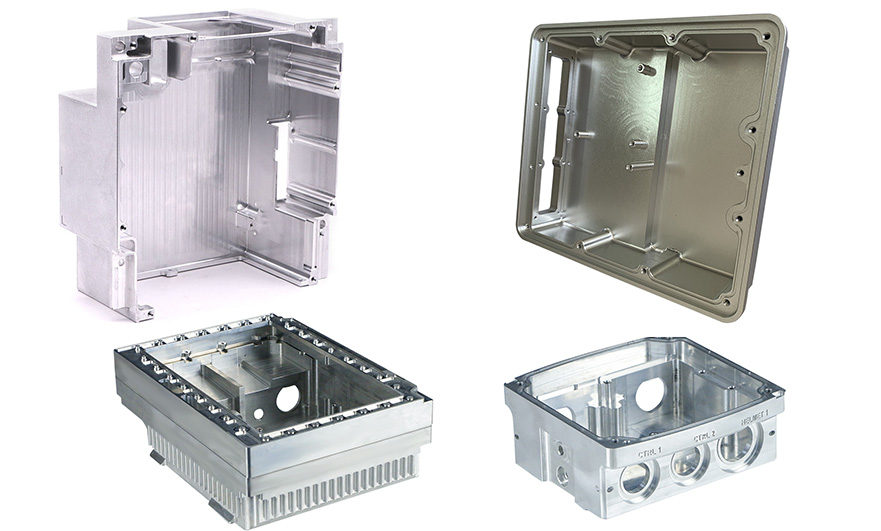

Aluminum is one of the lightest metals and is known for its softness, ductility, maneuverability and durability. Its appearance depends on the roughness of its surface, which makes it appear silver or dark gray in its pre-processed state. In addition, it lacks magnetism, and as a good conductive conductor, even if its conductivity is not as good as copper in a specific cross-sectional area. It is non-flammable and melts at about 640 degrees Celsius. In terms of its wide range of applications, aluminum is widely used in CNC automotive industries such as ATV, aerospace, and medical because of its optical density of 2.68.

Aluminum alloy cavity machining is an advanced technology with high efficiency, high quality and low consumption. Mechanical processing can solve the problems of easy deformation of traditional CNC machining parts, poor CNC machining quality, and poor surface texture. CNC machining can optimize the cutting path and select cutting parameters, thereby improving the efficiency of CNC machining and ensuring the quality of CNC machining.

CNC machining centers are mainly used for titanium processing of key mold parts such as mold cores, inserts, and copper parts. The quality of the mold core and inserts directly determines the quality of the molded parts. What problems should be paid attention to in the production of aluminum alloy cavity CNC machining?

1. Problems that should be paid attention to in the CNC machining of the front mold

1) Tool path sequence: wide tool curved surface groove tool path thick, small tool contour profile tool path thick, wide tool (ball cutter) parallel milling cutter path light, small tool parallel milling cutter path light. In the CNC machining of the front mold, there is usually a matching copper punch, which is mainly used for rough machining tools, supplemented by partially curved light tools.

2) For the parting surface and pillow surface, it takes some time. The pillow surface of the parting surface is CNC machined in place, without edges, and the edge in the cavity is 0.2~0.5. If there are only young people, then leave a gap of 0.3. When there are rough men and young men, the gap can be 0.5. The edge of the front mold and the friction position is 0.1, which can be reserved for front and rear mold matching.

3) Use a large-diameter round nose knife (knife handle) for roughing. If the tool diameter is too small, it is easy to break the knife and the knife. Try to use it on the middle knife.

4) According to the motion path of the tool center axis, calculate the tool path range in the surface titanium CNC machining, that is, the actual CNC machining area is one tool radius value larger than the selected tool path range limit box, and set the tool path range limit box reasonably parameter. Avoid exceeding the scope of CNC machining required for actual machining.

The front mold material is hard, so check carefully before CNC machining to reduce errors and not easy to weld!

2. Precautions for CNC machining of titanium after the mold

1 The order of the tool path of the back mold: rough machining of wide knife curved surface grooving, rough machining of small knife extreme surface grooving, transparent corner knife, big knife (ball knife) parallel milling cutter path smooth, small knife (ball knife) parallel milling cutter path limitation Clear angle, smooth knife, flat knife and other high profile tool path clear angle range.

2The material of the rear mold is the same as that of the front mold, so try CNC machining with a round-end knife (tool holder).

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!