15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

95 |

Published by VMT at Sep 04 2021

95 |

Published by VMT at Sep 04 2021

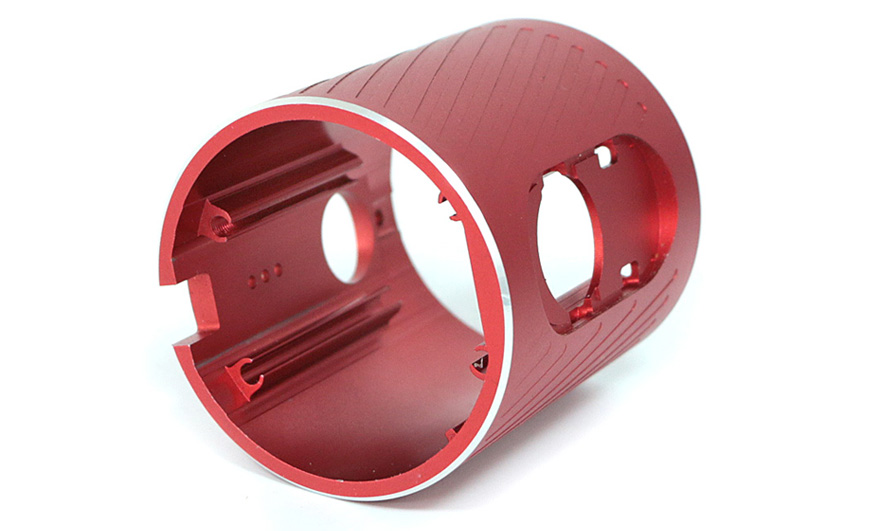

In order to pursue the beauty of the parts, the parts machined by CNC will be treated with some surface treatment. But sometimes after the parts are machined, the surface gloss is not enough, VMT will choose to do another highlight treatment, such as mobile phone frame, etc. This article mainly talks about aluminum bright edge treatment, if you are considering whether to do custom aluminum machining parts highlight edge treatment? If you are interested in this craft, you may wish to read it.

What is the high gloss edge of custom aluminum machining parts?

The highlight processing of custom aluminum machining parts is a relatively late CNC machining process. The aluminum machining part highlight is the effect of CNC milling along the edge of the aluminum part with a cutter on a CNC machining machine. Common highlight treatments include bright edge (C angle), bright surface, and CD pattern.

The high-gloss surface is whitish

Cutting fluid will cause some corrosion to custom aluminum machined parts. In an alkaline environment, under the action of air and cutting fluid, and the instant high temperature generated by cutting, the aluminum alloy will undergo an electrochemical reaction, which will cause corrosion white spots on the high-gloss surface. . The solution is that the custom aluminum machining parts should be soaked and cleaned in clean water immediately after the high-gloss machining, to avoid or reduce the formation of high-gloss white spots.

Horizontal lines appear on the chamfered high-gloss surface

The chipping of the high-gloss blade will cause horizontal lines on the high-gloss surface of the custom aluminum machining part product. When the tool is viewed under a microscope, even if it is only a little incomplete, horizontal lines will still be seen on the high-gloss surface of the custom aluminum machining part, which greatly affects the appearance level. The solution is to formulate a tool. The maximum single-side cutting allowance in the finishing program should not exceed 0.1MM, otherwise the tool will easily jump off the edge, resulting in horizontal lines.

Vertical lines appear on the chamfered high-gloss surface

There are generally three reasons for vertical lines in custom aluminum machined parts. One is that the cutting margin is too large, the other is that the cutting feed is too fast, and the third is that the spindle of the CNC machining machine has too much runout, which causes the tool to swing severely. The corresponding solution is:

1. The maximum single-side cutting allowance in the finishing program should not exceed 0.1MM, otherwise the tool will receive too much resistance, which will cause vibration, which will cause vertical vibration on the surface of the custom aluminum machined part.

2. The cutting feed control is a common and reasonable range from 3800mm/min to 4500mm/min. If the feed is too fast, the tool will receive more resistance, which will cause tool vibration, and the surface of the custom aluminum machined part will appear vertical. Vibrating knife pattern.

3. The aging of the spindle of the CNC machining machine, the collision, and the residue of waste debris will cause the tool to have unreasonable tool swings, resulting in vibration marks on the surface of the custom aluminum machining parts. First, wipe the inside of the spindle with a clean cloth, if there is still Vertical lines, after eliminating the program and tool factors, we must consider repairing the machine.

the vertical pattern knife line produced by the advance and retreat knife

There are generally two reasons for the vertical lines of the advancing and retreating knives on the surface of custom aluminum machined parts. One is that the programmer has not set the arc advancing and retreating knife overlap area, or setting the advancing and retreating knives on a straight line. The second is the aging of the CNC machining machine, and the accuracy of the spindle is unstable. The solution is:

1. Set the overlap area of the advance and retreat knife, and set the advance and retreat knife on the arc, or the intersection of the arc and the straight line.

2. Check and repair the CNC machining machine.

Summarize

After high-gloss machining of custom aluminum machining parts, it has good aesthetics. In product design, reasonable addition of high-gloss elements will give the custom aluminum machining parts the icing on the cake and the finishing touch.

Of course, it is also very important to choose the right custom aluminum machining parts highlight CNC machining manufacturers. VMT specializes in custom aluminum processing parts highlight 11 In 2015, with professional practitioners and top processing equipment, we can efficiently provide customers with high-quality and low-cost aluminum machining parts.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!