15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

448 |

Published by VMT at Jul 28 2021

448 |

Published by VMT at Jul 28 2021

Anodizing is the anodic oxidation of metal materials or CNC aluminum keyboard case , and an electrolytic method is used to produce an oxide film on the surface. The metal oxide plastic film changes the surface state and performance: such as surface coloring, improved corrosion resistance, improved wear resistance and strength, and maintenance of the surface of CNC aluminum keyboard case. Due to the porous material of the oxide film, the etching material easily deepens the pores of the film and etches the substrate.

The sealing liquid seals the pores of the film, improves the safety and protective performance of the film, and maintains the actual effect of film coloring. Generally, the anodic oxide film and its colored oxide film need to be sealed, unless it is a hard oxide film, phosphoric acid anodic oxide film and other special requirements whose main purpose is multi-function.

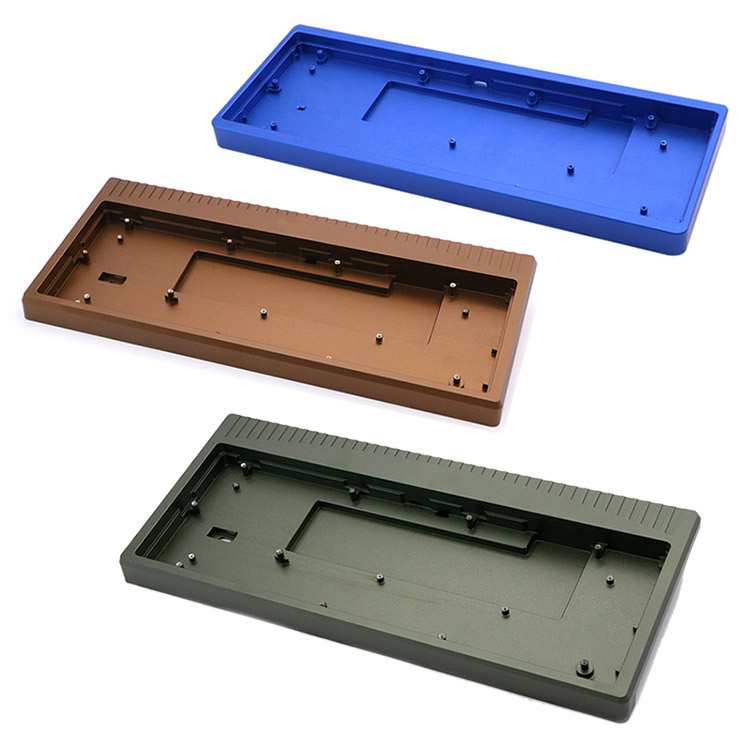

The color of anodizing ranges from brown to blue, red, white, green, black, gray, desert color, etc., so you can customize the color according to your preferences. Make your CNC aluminum keyboard case with high quality and beautiful surface finish.

For xample:

The anodized structure of CNC aluminum keyboard case can be roughly divided into three layers: porous layer, barrier layer and substrate. Due to the porous structure of the anodic oxide film, the surface of the anodic oxide film is relatively rough and easy to adhere to color. Unlike anodic oxidation, the naturally formed oxide film generally only has an aluminum substrate and a barrier layer.

Density

The relative density of the aluminum alloy profile oxide film varies with the type of aluminum alloy profile and anodizing. The CNC aluminum keyboard case surface density decreases as the film thickness or electrolyte temperature increases.

Hardness

The Mohs hardness of the anodic oxide film itself is around 7-8, which is between crystal and corundum. The hardness of the membrane is affected by the type of electrolyte, the influence conditions of the electrolysis and the influence conditions of the material; for example, the lower the temperature of the electrolyte, the higher the hardness of the hydrochloric acid membrane.

The anodic oxide film itself is completely transparent, and its transparency is affected by the purity of raw materials and aluminum alloy elements. The higher the purity of the metal material, the better the transparency.

Electrical Characteristics of Anodizing

Anodized film is a high-resistance conductor and insulator. At high temperatures, the resistance hardly decreases. Can be used as conductors and insulators of conductive elements such as cables and wires; the breakdown voltage of the insulating layer is basically positively correlated with the film thickness, so the breakdown voltage can be used to measure the thickness of the oxide film.

If the discharge wire cutting is to be performed after anodizing, the actual operation that requires the conductivity of the CNC aluminum keyboard case workpiece is not feasible. The usual method is to remove the oxide layer and start the production process.

CNC aluminum keyboard case anodizing can be divided into the following categories according to its purpose:

Anticorrosion: sulfuric acid method, oxalic acid method, chromic acid method, other organic acid methods

Wear resistance: hard anodizing (oxalic acid, sulfuric acid)

Decoration: Sulfuric acid (dyeing)

Optical: using sulfuric acid method

Paint bottom layer: sulfuric acid method, chromic acid method

Electroplating bottom layer: phosphoric acid method

Coloring of building materials: natural hair dyeing method, electrolytic coloring method

In the selection of CNC aluminum keyboard case materials, we always consider the appearance, feel and other sensory things, and always ignore the nature and price of some materials. The following introduces the commonly used materials for processing CNC aluminum keyboard case.

1. Aluminum

2. Stainless steel

3. Titanium

4. Copper

Of course, there are also unusual materials, such as titanium damascus, Acrylic etc.

The CNC aluminum keyboard case has different sizes. For example: Full-Size or 100%, 1800-Compact, Tenkeyless (80%, 87%, TKL), 75% Size, 60% Size, 40% Size, etc. You can also provide 2D/3D drawings, we can customize machining according to your drawings, and the drawings can sign a confidentiality agreement.

The CNC aluminum keyboard case will have different effects on different materials, and the oxidation treatment will naturally affect the final CNC machining cost.

VMT can help you understand the surface treatment of CNC aluminum keyboard case, and can provide you with a one-stop design solution. Our professional manufacturer team has deep industry knowledge and experience, and we will work hard to make your next project a success. Contact us now to start your CNC aluminum keyboard case journey.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!