15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

158 |

Published by VMT at Jul 24 2021

158 |

Published by VMT at Jul 24 2021

One of the problems in precision turned parts components manufacturing is the problem of translating customer needs into final product design. The manufacturers agreed that the production process must be improved. Assembly design is particularly important because it can ensure that precision turned parts components manufacturers remain relevant and meet customer requirements.

Over the years, the entire process of product development and design has undergone tremendous changes. This is because the design of the whole process of manufacturing and assembly is conducive to the rapid production and manufacture of precision turned parts components, mainly for cost control.

In the article, everyone will carefully study the necessity of assembly design, DFA manual and precision turned parts components production process. Let VMT lead everyone to get started now.

What is precision turned parts components assembly design?

DFA assembly design is the whole process of product design, and is committed to simplifying product design on the basis of reducing the total number of precision turned parts components. Therefore, it minimizes the cost and improves the convenience of assembly.

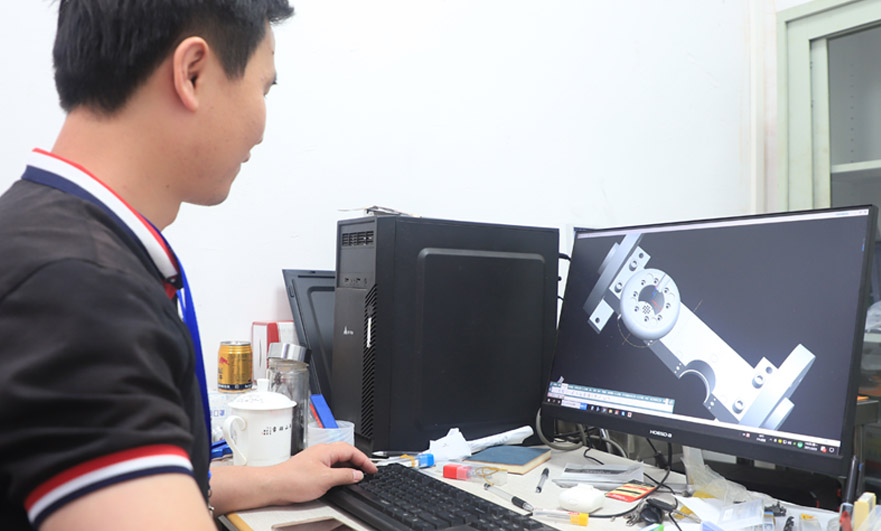

As a professional tool, DFA can assist the elite team of precision turned parts components design because it allows the product design to be improved before a specific production. Therefore, they can be very concerned about the function of the precision turned parts components and the ease of assembly.

Fewer assembly precision turned parts components in the product means that the product is easier to assemble, requires less time, and can minimize assembly costs.

The main overall goal of DFA is to minimize costs and reduce precision turned parts components assembly parts. As we all know, its application in product design has improved the quality and durability of the product, and reduced the inventory of precision turned parts components and production line equipment.

The necessity of assembly design

DFA improved the design and eliminated multiple design revisions and changes. Therefore, it eliminates precision turned parts components manufacturing delays and allows new products to be manufactured quickly.

Control costs

1. DFA ensures a stronger product design at a lower cost. This is because it uses fewer components in product design.

2. DFA eliminates the need for repeated experiments in the production process. Therefore, it reduces the consumption of precision turned parts components manufacturing raw materials. It has a higher chance of making reliable products.

3. DFA ensures more reliable products by reducing the total number of assembled precision turned parts components, thereby reducing the probability of common failures.

Disassemble

Although the assembly design is dedicated to simplifying the entire assembly process, it also reduces the entire disassembly process. It is essential because it ensures the maintenance and overhaul of the precision turned parts components.

Automation technology

As the assembly parts are aligned at both ends of the equipment or intelligent robot, the assembly design gives the automation technology of the production process. This self-direction ensures fast and easy precision turned parts components manufacturing.

Application of DFA design in assembly

The design of precision turned parts components manufacturing and assembly applications involves all walks of life that solve the design of daily necessities.This situation is also more serious in units that have high product requirements but still want to maintain high quality and high efficiency.

In many CNC machining companies, precision turned parts components manufacturing and assembly design is a key requirement. For example, some companies want to reduce precision turned parts costs, while others want to produce a large number of products without hiring a lot of human capital. The overall goal of some other CNC machining companies may also be to simplify their precision turned parts components and improve their stability.

Regardless of the different requirements of these companies, the assembly design is suitable for their precision turned parts components production process and ensures the results they want.

The difference between DFA and DFM

It is especially important to inspect the product and find ways to improve its design and function. This type of improvement is usually based on 2 complete processes:

Design for Assembly (DFA)/Design for precision turned parts components Manufacturing (DFM), these two overall processes have similar effects in improving product design and functionality. However, they have some changes.

Summarize

The production process accounts for a large part of the cost of precision turned parts components manufacturing. In most cases, the entire process is likely to be complicated and time-consuming.

However, assembly design is based on step-by-step simple design steps to simplify products, control costs and ensure rapid precision turned parts components assembly, thereby ensuring a reasonable overall planning.

Break down your precision turned parts components into standardized smaller modules, including pre-assembled components integrated into various products. Therefore, you can guarantee easy assembly and on behalf of technical engineers can easily apply parts in overhauls. Make the precision turned parts components unique and distinguishable.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!