15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

209 |

Published by VMT at Jul 17 2021

209 |

Published by VMT at Jul 17 2021

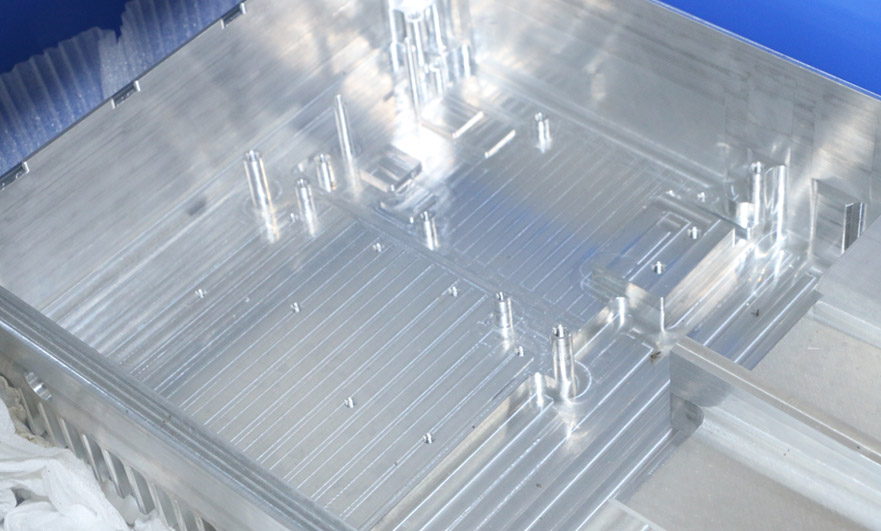

In the CNC machined parts process, chamfering is the most common structural feature of parts. There are usually two types of chamfering and rounding. Generally, the function of chamfering is to remove burrs, and there is some special emphasis on chamfering for installation process requirements, such as installation guidance, reduction of stress concentration, and ease of assembly.

The function of rounded corners is that where the size of the casting changes drastically, there must be a rounded corner transition to prevent the gravitational concentration of the workpiece. Both chamfering and rounding have certain advantages, especially when increasing the corner strength of the CNC machined parts by reducing stress concentration. Of course, including fillets and chamfers in your design may incur additional CNC machined parts costs and sometimes affect the project schedule. On these issues, we VMT will discuss them with you.

Advantages and disadvantages of chamfering and rounding

Due to the rounded edges of the rounded corners, the physical stress of the rounded corners is distributed to a wider area with a lower stress concentration factor, which helps to improve the assembly of CNC machined parts and mating parts. The rounded corners can easily bear larger loads. Rounded corners are usually safe and durable.

The smooth edges created by the rounded corners can also be coated and painted more easily. In contrast, chamfering will cause the coating to follow the angle and it will fall off over time.

Although chamfers are more prone to natural wear due to their sharp edges, these edges are hidden and therefore much safer than corners. When assembling mating CNC machined parts together, the chamfer is more tolerant than the rounded corner. They are particularly suitable for allowing male parts to easily enter female CNC machined parts during assembly, because the chamfered holes allow smooth movement and insertion. More importantly, chamfers can be applied quickly and easily, because one tool can create chamfers of various sizes.

What should be paid attention to when using chamfering and chamfering in CNC machined parts?

In order to make it easier for you to know whether chamfering or rounding is included in the product design, you should consider many factors. From the aspects of CNC machined parts function, position tolerance, cost and so on.

1. Function

Keep in mind the end use of the CNC machined parts product. Is it easy to damage the environment because of its sharp edges and corners? Will the part be used for load-bearing applications, and if so, how much weight must the CNC machined parts bear? Consider whether the function of the product depends on the presence of chamfers or rounded corners.

For example, does the part need to be painted or coated, and does the varnish need to wear for a long time? Does the component need to be exactly matched to the mating part, or is there some leeway? Answering these questions will help determine which corner you should use.

2. Location (internal and external)

It is important to consider whether the corner you are designing is inside or outside the CNC machined parts. In most cases, it is more important to fully consider the outer edges because they are more conspicuous, more susceptible to external conditions and wear over time.

However, when designing a hole suitable for the shaft, it is also important to consider chamfering or rounded inner corners. It is recommended to chamfer along the edge of the hole, because the chamfered hole helps to move the pin and make it easier to insert the fastener.

3. Tolerance

Optimizing dimensional tolerances is a key part of product design, especially in mating CNC machined parts. Determine the accuracy your product needs to achieve, and how incorrect measurements will affect the product’s functionality and fit.

In addition, ask yourself the importance of tolerances to ensure CNC machined parts performance, and consider how to check tolerances. Keep in mind that applying extremely tight tolerances can be expensive, and chamfering usually allows a larger margin of error.

4. Cost

Applying chamfers and fillets can be expensive. Take a moment to consider whether rounding or chamfering is the key to the success of the CNC machined parts, or just an additional benefit. If you really need a dedicated corner, please consider how many components you have to produce, as this will also affect the CNC machined parts cost.

Although it is often necessary to apply chamfers and fillets in component design, make sure you are absolutely positive before spending time, money, and resources on manufacturing tools.

After considering these issues, we will consider other factors, such as CNC machined parts time cost and aesthetics, and the size of the production scale. Use these questions to further guide your decision-making process between chamfering and rounding.

How do chamfering and filleting affect CNC machined parts costs?

Manufacturing professional corners usually requires additional financial costs. Generally speaking, the CNC machined parts cost of making chamfers is lower. This is because one tool can create chamfers of various sizes, simplifying production and saving time and resources.

However, from the perspective of long-term applications, although the cost of using special tools for rounding CNC machined parts will increase rapidly, because rounded corners can avoid the need for intermittent repainting or repainting, and reduce the risk of detection failure due to sharp corners.

VMT welcomes everyone to come to our official website for consultation. Of course, you can also send us an email, we will reply you as soon as possible and provide you with a solution. Please feel free to contact us and look forward to your CNC machined parts projects.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!