15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

124 |

Published by VMT at Jul 10 2021

124 |

Published by VMT at Jul 10 2021

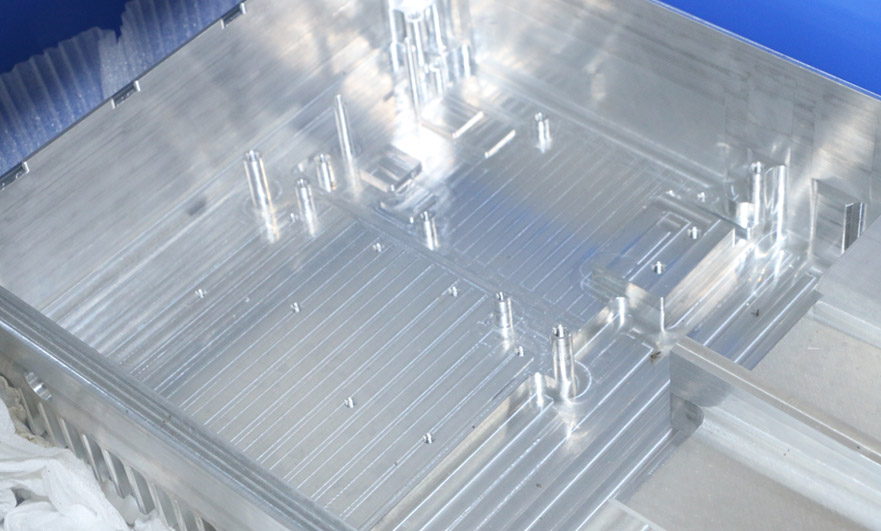

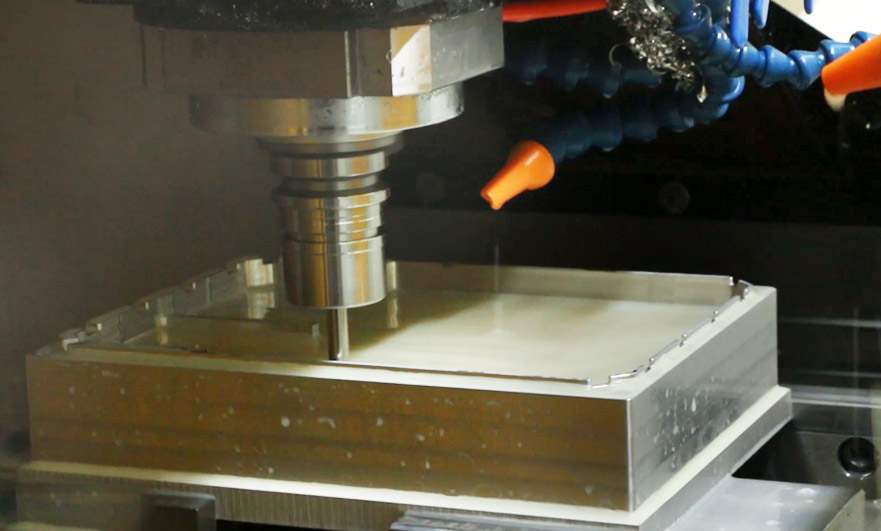

The CNC machining center is also called cnc CNC milling machine. It is a milling machine that uses a computer for signal control. CNC machining is an essential equipment for processing high-grade aluminum CNC machined components parts. The quality and quality of parts can be improved more accurately, but the processing process is affected by many factors. When knife marks appear in many CNC machined components parts, they often affect the appearance of the product, and may even directly damage the product, thereby affecting the quality and brand value of the customer's product. Next, let us follow the VMT engineers to study and understand these factors we encountered in the process.

What is a knife pattern?

The reason

Generally speaking, tool marks appear in CNC machining components parts because of excessive speed, tool wear, excessive feed, or parts that are not clamped.

1. The speed is too slow or too fast. Different materials have different speeds. Not all materials are as fast as possible. Generally, the linear speed we use when making aluminum alloy CNC machined components parts is close to 600-800 m/min.

2. Tool wear is too fast, and the wear caused by mechanical action. Choose different tools according to different materials. You can also consider using coated tools or changing the cutting fluid.

3. The amount of knife is large, choose the amount of knife according to the structure and material of the CNC machined components parts. The rough machining is generally 0.4MM~0.6MM on one side, and the fine machining on one side is 0.05MM-0.075MM.

4. The clamping of CNC machined components parts is unstable, and the vibration in the processing process causes the knife vibration to produce knife marks.

5. Insufficient coolant, friction between the tool and the surface of the CNC machined components parts during processing. The knife is not smooth, resulting in knife marks.

6. When titanium alloy CNC machined components parts, the speed of the knife is slower. Generally, the speed of finishing is controlled within 500 meters per minute, and the surface knife marks will be less.

How to adjust the knife shape?

When a CNC machined components parts with a knife pattern appears, we first analyze where it is. If it is roughing and finishing, we have to distinguish which tool is causing it, and then find out the reason.

1. On the tool, we consider whether the cutting fluid is aligned with the tool, and whether the concentration of the cutting fluid can meet the requirements?

2. In terms of speed, we consider whether the cutting force is adjusted too fast, whether the tool has relatively large wear, whether the processing path of the tool is reasonable, and whether the speed feed is appropriate

3. In the surface finish, the speed should be adjusted appropriately to improve the CNC machined components parts.

4. When adjusting the clamping pressure plate, consider whether it is reasonable and whether the pressure plate is clamped on the CNC machined components parts. If it is not pressed tightly, vibration marks will be produced during processing. Whether there are aluminum chips in the spindle tool holder and taper hole, whether there is debris in the fixture when installing the tool, measure the tool with a dial gauge to observe whether the deflection is within the standard range, and follow the above treatment to avoid similar situations.

TO sum up

When a CNC machined components parts knife pattern appears, you should look at the tool, speed, surface finish, and whether the clamp plate is reasonable, etc., to know the real cause of the tool. The above is some experience of our engineers encountering tool marks during VMT processing. Hope it helps you.

VMT is your hardware processing partner. We effectively combine our experience, expertise and small batch facilities to bring your CNC machined components parts from production to market in a short period of time. Provide you with a quote within a few minutes.

Welcome to visit our VMT official website for information. Thank you for your review and look forward to your next CNC machined components parts project.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!