15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

1058 |

Published by VMT at Jul 27 2021

1058 |

Published by VMT at Jul 27 2021

The operation techniques and activities adopted in the CNC machining process to meet the quality requirements are called quality control. In other words, quality control is to eliminate the factors that cause unqualified or unqualified results at each stage of the quality cycle by monitoring the quality formation process. Various quality operation techniques and activities adopted to meet quality requirements and obtain economic benefits.

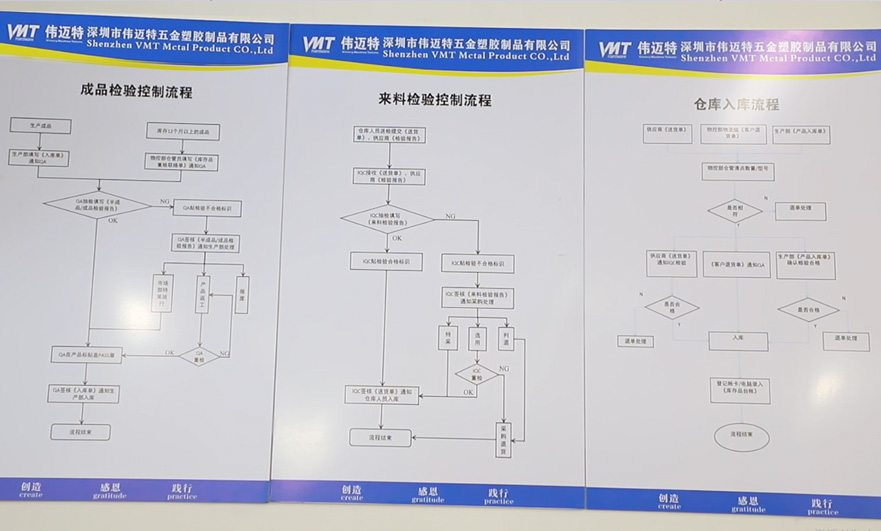

1. Incoming material (goods) inspection (IQC): It is the primary control point for the factory to prevent unqualified materials from entering the production process.

①Incoming inspection items and methods:

a) Appearance: generally use visual inspection, hand feel, and comparison samples for verification;

b) Dimensions: generally verified by measuring tools such as calipers and micrometers;

c) Characteristics: such as physical, chemical, and mechanical characteristics, which are generally verified by testing instruments and specific methods.

②Incoming material inspection method:

a) Full inspection,

b) Sampling.

③Processing of inspection results:

a) receive;

b) Rejection (ie return of goods);

c) Concession acceptance;

d) Full inspection (select non-conforming products to return);

e) Re-inspection after rework.

④ Standard basis: "Technical Standards for Raw Materials and Purchased Parts", "Incoming Material Inspection and Test Control Procedures", "Physical and Chemical Inspection Regulations", etc.

2. Production process inspection (IPQC): generally refers to the quality control of the production activities at each stage after the material is put into the warehouse to before the finished product is put into the warehouse, that is, Inprocess Quality Control. Compared with the current quality inspection, it is called FQC (Final Quality Control).

①The main methods of process inspection are:

a) Combination of first article self-inspection, mutual inspection and special inspection;

b) Combine process control with random inspection and patrol inspection;

c) Multi-process centralized inspection;

e) Inspection after the product is completed;

f) Combination of sampling and full inspection.

②Process Quality Control (IPQC): Carry out roving inspections of the production process.

a) First article inspection;

b) Material verification;

c) Inspection: Ensure proper inspection time and frequency, and conduct inspections in strict accordance with inspection standards or work instructions. Including product quality, process regulations, machine operating parameters, material placement, identification, environmental inspections etc;

d) The inspection record should be filled in truthfully.

③Process product quality inspection (FQC): It is the quality verification after the product is completed to determine whether the batch of products can flow into the next process, which is a fixed-point inspection or acceptance inspection.

a) Inspection items: appearance, size, physical and chemical properties, etc.;

b)Inspection method: sampling inspection is generally adopted;

c) Disqualification treatment;

d)Record.

④ Standard basis: "Operation Regulations", "Process Inspection Standards", "Process Inspection and Test Regulations", etc.

3. Final inspection control: finished product shipment inspection. (Outgoing Q.C)

4. Feedback and handling of abnormal quality:

①If you can judge by yourself, directly notify the operator or the workshop to deal with it immediately;

② If you cannot judge by yourself, please submit the bad model to the supervisor for confirmation, and then notify you to correct or deal with it;

③Record the abnormal situation truthfully;

④ Confirm corrective or improvement measures, and track the treatment effect;

⑤ The inspection of semi-finished products and finished products should be clearly marked, and the relevant departments should be supervised and stored separately.

5. Quality records: Provide objective evidence for the completed quality operation activities and results.

a) Must: be accurate, timely, clear, complete and affixed with an inspection seal or signature.

b) It must also be done: timely sorting and filing, and storing in a suitable environment.

This is our quality inspection process. Our goal is to provide high-quality parts that meet your requirements and expectations. If you want to know more, please contact the VMT precision metal parts machining website for details.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!