15 years one-stop China custom CNC machining parts factory

888 |

Published by VMT at Jul 05 2024

888 |

Published by VMT at Jul 05 2024

Introduction

In the field of CNC machining and component manufacturing, brass is a popular metal material due to its excellent machining properties and attractive golden appearance. However, achieving the desired smoothness and aesthetics for brass CNC machined parts requires effective polishing techniques. This article provides a comprehensive guide to polishing brass, covering the preparation of polishing tools, pre-polishing cleaning, the polishing process, different types of polishing surface treatments along with their advantages and disadvantages, applications of polished brass CNC machined parts, and answers to common questions. The goal is to offer a thorough and professional guide for polishing brass.

How to Perform Brass Surface Polishing?

Preparing Polishing Tools

Before starting the polishing process for brass, a set of essential tools must be prepared to ensure a smooth operation. Here’s a basic checklist of tools required for polishing brass:

Soft Cloth: For initial wiping of dust and dirt from the brass surface.

Brush: To clean hard-to-reach crevices and grooves.

Wet Abrasives: Choose sandpaper or sanding discs of various grits depending on the initial condition of the brass surface.

Polishing Compound: Commercial brass polishing agents or homemade polishing solutions for the final polishing of the brass surface.

Rubber Gloves: To protect hands from polishing agents and chemicals.

Safety Goggles: To prevent eye injury from debris during the polishing process.

Mild Detergent: For cleaning oil and stains from the brass surface.

Bowl or Container: For holding polishing agents and washing brass parts.

Pre-Polishing Cleaning of Brass

Removing Dust and Dirt: Wipe the brass surface with a soft cloth and mild detergent to remove dust, oil, and other contaminants. For stubborn stains, use a brush.

Removing Rust: If there is rust on the brass surface, use a rust remover or sandpaper to gently remove it, taking care not to damage the brass substrate.

Thorough Drying: After cleaning, dry the brass surface thoroughly with a clean cloth to ensure no moisture remains.

Polishing Brass

Polishing Process

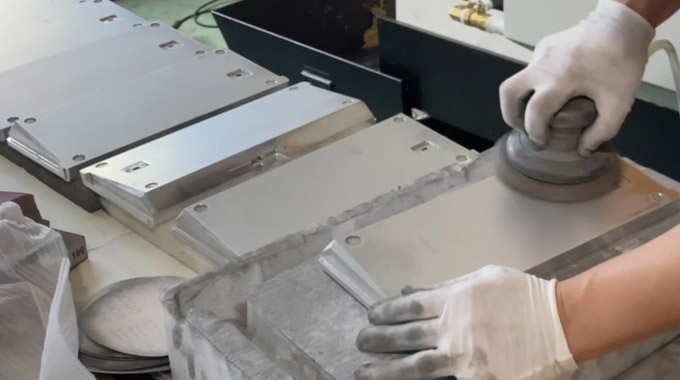

Before polishing, it is usually necessary to sand the brass surface to remove imperfections and scratches. Choose suitable sandpaper or sanding discs based on the initial condition of the brass surface. Follow a coarse-to-fine sanding approach, gradually increasing the grit of the abrasives until the surface becomes smooth.

Choosing the Right Polishing Compound

Commercial Brass Polishing Compounds: There are various commercial brass polishing agents available that are efficient and easy to use. Follow the instructions on the product label to ensure effective and safe polishing.

Homemade Polishing Solutions: For special needs or cost control, you can create your own polishing solution. Homemade solutions usually contain common chemical ingredients such as acetic acid or citric acid. By mixing these ingredients and adjusting ratios, you can make a suitable polishing solution for brass. However, creating a homemade solution requires some chemical knowledge and experimental experience to ensure safety and effectiveness.

Polishing Process

Rough Processing: Use wet abrasives for initial rough processing to remove visible scratches and surface imperfections. Control the sanding force and angle to avoid damaging the brass substrate.

Choosing Your Tools: Depending on the polishing stage, select appropriate tools. For rough processing, use sandpaper or sanding discs; for fine processing and final polishing, use soft cloths, sponge wheels, or polishing machines.

Applying Polishing Compound: Evenly apply the polishing agent or compound on the brass surface, ensuring full coverage for optimal polishing results.

Polishing the Brass Surface: Use the selected polishing tool to polish the brass surface. Maintain uniform pressure and movement speed to avoid over-polishing or damaging the surface.

Brightening: After achieving a shiny, golden surface, clean off any remaining polishing compound with water and a clean cloth. The brass surface should now have a uniform, bright metallic luster.

Protecting and Maintaining Shine: To maintain the brass surface's luster, apply a brass protector or coating to form a protective layer against oxidation and corrosion.

Different Types of Polishing Surface Treatments and Their Advantages and Disadvantages

Mechanical Polishing

Advantages:

Effective Polishing: Provides a good polish and removes surface imperfections and scratches.

Versatile: Suitable for various shapes and sizes of brass parts.

Controlled Process: Allows adjustment of polishing force and angle as needed.

Disadvantages:

Slow Process: Requires more time for processing.

Heat and Dust: May generate heat and dust, requiring protective measures.

Chemical Polishing

Advantages:

Fast Process: Quickly removes surface oxides and stains.

Easy Operation: Suitable for bulk processing of brass parts.

Consistent Results: Achieves a uniform polishing effect.

Disadvantages:

Environmental Impact: Requires chemical agents that need proper disposal.

Post-Polishing Wash: Requires thorough rinsing to remove chemical residues.

Limited Suitability: Not suitable for all brass alloys; pre-testing is recommended.

Electrolytic Polishing (Electropolishing)

Advantages:

High Efficiency: Achieves mirror-like finishes quickly.

No Mechanical Contact: Prevents scratches on the brass surface.

Complex Shapes: Suitable for intricate parts and difficult geometries.

Disadvantages:

High Cost: Requires specialized equipment and has a higher initial investment.

Technical Expertise: Requires precise control of current, voltage, and time.

Post-Polishing Care: Needs immediate washing and drying to prevent corrosion.

Mechanical Polishing vs. Electrolytic Polishing: Which is Better for Brass CNC Machined Parts?

When choosing between mechanical polishing and electrolytic polishing, consider the following aspects:

Cost:

Mechanical Polishing: Lower equipment costs but higher labor and time costs, especially for large or complex parts.

Electrolytic Polishing: Higher initial investment but can significantly reduce labor and time costs in a fully automated production line.

Advantages:

Mechanical Polishing: Flexible, adjustable for various parts.

Electrolytic Polishing: High efficiency, achieves high gloss and uniform surface.

Smoothness:

Both methods can achieve high smoothness, but electrolytic polishing might achieve a finer finish in certain cases due to the lack of mechanical contact.

Corrosion Resistance:

Post-polishing protection is crucial for both methods, with no significant differences in corrosion resistance between mechanical and electrolytic polishing.

Wear Resistance:

Both methods provide similar wear resistance improvements depending on the final treatment and brass alloy composition.

Applications of Polished Brass CNC Machined Parts

Polished brass CNC machined parts are widely used in various fields such as decoration, construction, electronics, and machinery. The high gloss and aesthetic appeal of polished brass make it a valuable element for enhancing product quality and visual appeal. For example:

In Construction: Polished brass fittings like door handles and railings add a touch of luxury.

In Electronics: Polished brass parts are used for high-end product housings and components.

In Machinery: Polished brass parts improve the appearance and corrosion resistance of machinery.

Advantages and Disadvantages of Polished Brass Surface Finish

Advantages of Polished Brass Surface Treatment

Enhanced Aesthetics: A smooth, shiny brass surface enhances visual appeal with a metallic sheen.

Increased Corrosion Resistance: Polishing removes oxides and contaminants, creating a protective layer.

Improved Texture: Provides a smooth, refined touch for better user experience.

Disadvantages of Polished Brass Surface Treatment

Higher Cost: Requires specialized equipment and processes, increasing production costs.

Environmental Impact: Chemical and electrolytic polishing processes may generate waste that needs proper management.

Maintenance: Polished surfaces require regular maintenance to keep their luster.

VMT's CNC Machining Manufacturing Services and Solutions

VMT offers comprehensive solutions for polishing brass CNC machined parts. With advanced CNC machining equipment and a professional polishing team, VMT provides high-precision, high-quality brass parts tailored to client needs. Our solutions cover the entire process from design and machining to polishing, ensuring each brass part meets client expectations.

Tips for Custom CNC Brass Part Surface Polishing

Select Appropriate Tools: Choose tools and materials based on the part's shape, size, and surface condition.

Control Polishing Force and Speed: Avoid over-polishing and maintain moderate polishing speed for efficiency.

Follow Polishing Sequence: Progress from coarse to fine processing to achieve the desired polishing effect.

Clean and Dry: Remove dust and residues promptly to prevent corrosion.

Protective Treatment: Apply a protective coating to enhance corrosion and wear resistance.

Common Questions about Polishing Brass Surface Finish

What is the Main Purpose of the Polishing Process?

The main purpose of polishing is to remove surface imperfections, scratches, oxides, and contaminants from brass to achieve a smooth, even, and shiny surface. This enhances the brass part’s appearance, corrosion resistance, and overall performance, making it suitable for various applications in decoration, construction, electronics, and machinery.

What is the Difference Between Polishing and Sanding?

Purpose: Sanding removes rough layers and major imperfections; polishing refines the surface to achieve high gloss and smoothness.

Method: Sanding uses coarse abrasives; polishing uses finer abrasives or compounds for detailed finishing.

Effect: Sanding leaves a smooth surface but may still have fine scratches; polishing creates a high-gloss, mirror-like finish.

What is a Polishing Compound?

A polishing compound is a chemical or material used to refine and smooth the surface of a material. It typically contains abrasives, lubricants, and surfactants. Polishing compounds vary by application, such as metal, plastic, or glass polishing agents. For brass, common polishing compounds include commercial brass polishes and homemade solutions, which remove oxides, stains, and scratches to restore metallic shine.

Conclusion

Polishing brass is a crucial process in CNC machining and component manufacturing that significantly improves the appearance, corrosion resistance, and wear resistance of brass parts. By selecting the right polishing tools, controlling process parameters, choosing suitable compounds, and applying protective treatments, you can achieve the ideal polishing results. Each type of polishing method has its own set of advantages and disadvantages, and the choice depends on specific requirements and conditions. With ongoing advancements in CNC machining technology and polishing techniques, the quality and performance of polished brass CNC machined parts will continue to evolve, offering high-quality and efficient solutions for various industries.