15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

502 |

Published by VMT at Jul 06 2024

502 |

Published by VMT at Jul 06 2024

Introduction

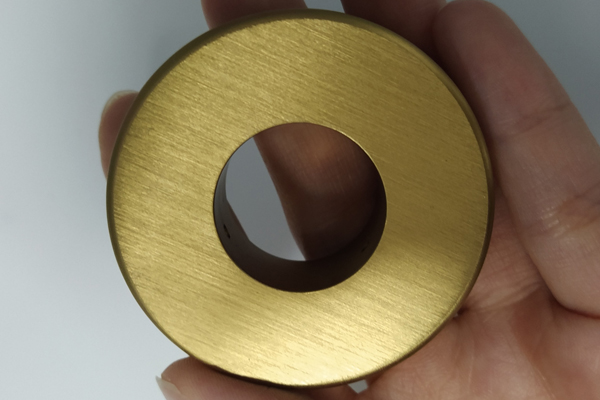

In the field of CNC machined parts manufacturing, brass is a favored metal material due to its excellent machinability, corrosion resistance, and aesthetic appeal. Among them, brushed brass stands out in various applications due to its unique surface texture and tactile feel. This article aims to delve into all aspects of brushed brass, from the brushing process, factors affecting surface finish, the brushing process itself, typical applications, the pros and cons of its use in CNC machining, to custom techniques and common FAQs in VMT's CNC machining manufacturing services, providing you with comprehensive knowledge and insights.

Brushing Process

Overview of Brushing Process

The brushed brass process is a mechanical treatment that creates fine grooves on the surface of brass. This process is mainly achieved through a brushing machine, which scrapes the metal surface to form fine grooves in a specific direction, thereby increasing the surface friction coefficient, corrosion resistance, and hardness. Additionally, this process endows the brass surface with a unique texture and feel, enhancing its decorative effect.

Factors Affecting the Surface Finish of Brushed Brass

Several factors influence the surface finish of brass during the brushing process, with the type of brush being a critical factor. Common brushes include standard brushes, wire brushes, and electric brushes, each with its specific application scenarios and effects.

Standard Brushes: Suitable for initial cleaning and deburring but limited in creating fine texture effects.

Wire Brushes: More effective at removing surface roughness and forming more uniform fine grooves but require controlled force to avoid scratching the surface.

Electric Brushes: Powered by electricity, highly automated, capable of quickly and uniformly treating large surface areas but require stable operation to prevent excessive brushing.

Brushing Process Steps

The brushing process for brass typically includes material preparation, polishing, initial brushing, intermediate brushing, and final brushing. Each step requires precise control to ensure the quality and appearance of the final product.

Material Preparation: Process the brass material to the required specifications, ensuring no cracks or inclusions on the surface.

Polishing: Improve the flatness and smoothness of the brass surface through polishing, laying a good foundation for subsequent brushing treatment.

Initial Brushing: Use a brushing machine to initially treat the brass surface, forming basic fine grooves, typically about 0.2mm in width.

Intermediate Brushing: Further deepen the surface grooves to create more refined textures, with a groove width controlled between 0.05-0.15mm.

Final Brushing: The final processing step, further deepening and refining the surface grooves, improving hardness and oxidation resistance, with a groove width controlled between 0.02-0.04mm.

Typical Applications of Brushed Brass

Brushed brass technology has a wide range of applications, primarily in deburring, edge blending, cleaning, and roughening.

Deburring: Brushing effectively removes burrs and small protrusions on brass parts, improving the overall smoothness of the product.

Edge Blending: Brushing the edges of parts makes them smoother, reducing sharpness and improving safety.

Cleaning: The brushing process removes dirt and oxide layers from the surface, enhancing the cleanliness and aesthetics of brass parts.

Roughening: In some applications, increasing the surface roughness of brass to enhance adhesion or anti-slip performance is required, which brushing technology can achieve.

Pros and Cons of Brushed Brass CNC Machined Parts

Pros:

Improved Surface Texture: Brushing imparts a unique texture and feel to the brass surface, enhancing the product's aesthetics and grade.

Enhanced Physical Properties: Brushing increases the surface friction coefficient, corrosion resistance, and hardness of the brass.

Excellent Machinability: Brass is one of the easiest alloys to machine in CNC processes, with 100% cutting efficiency and high processing efficiency.

Cons:

Higher Costs: Compared to ordinary brass parts, brushed brass parts have higher processing costs, including material costs, processing time, and equipment wear and tear.

Processing Difficulty: The brushing process requires precise control, with high technical requirements for operators and equipment accuracy.

Surface Susceptibility to Damage: The brushed brass surface is relatively fragile and can be easily damaged during transportation and installation.

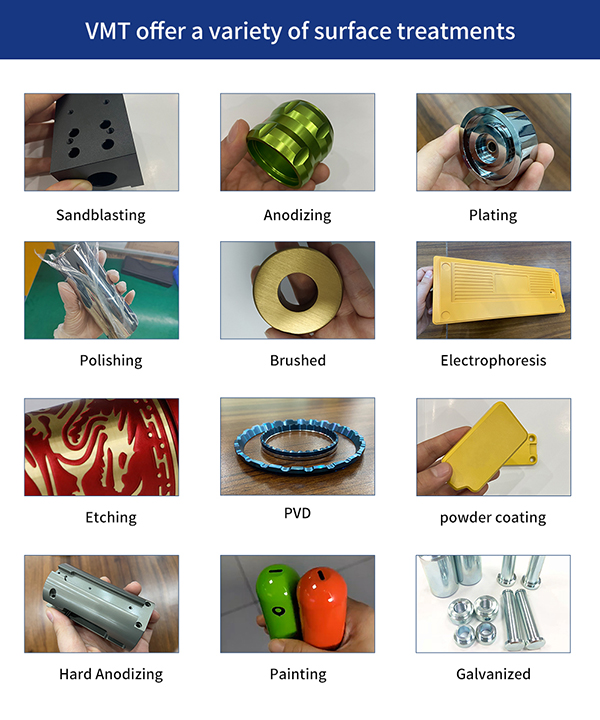

VMT CNC Machining Manufacturing Services: Metal Surface Treatment Experts

As a professional metal surface treatment expert, VMT offers custom CNC brass parts surface brushing services. With advanced machining equipment and extensive experience, we can customize brushed brass parts of various specifications and textures according to customer needs. We focus on quality control and technological innovation, committed to providing customers with high-quality, efficient processing services.

Custom Techniques for Brushed CNC Brass Parts

Use the Highest Possible Safe Speed: Increase processing speed as much as possible without compromising quality to improve production efficiency and reduce costs.

Understand Brush Types: Select the appropriate brush type based on the surface condition of the parts and processing requirements to achieve the best brushing effect.

Avoid Single-Direction Brushing: Avoid single-direction brushing during the process to prevent forming visible texture directions that affect aesthetics.

Heat-Treated and Oil-Tempered Wire Brushes Provide Best Results: Choose wire brushes that have undergone appropriate heat treatment and oil tempering to maintain brush hardness and toughness, reduce brush wire breakage, and ensure the uniformity and delicacy of the brushed brass surface.

Keep Stainless Steel Brushes Clean: Regularly clean and replace worn brushes to prevent metal debris or impurities on the brush from scratching the brass surface, maintaining the stability and consistency of the brushing effect.

Precisely Control Brushing Depth: Precisely control the feed and pressure of the brushing machine according to the specific requirements and design of the parts to ensure uniform brushing depth and avoid uneven surfaces due to excessive or insufficient brushing.

Use Appropriate Coolant: Reasonable use of coolant during brushing can lower processing temperatures, reduce the impact of thermal stress on brass materials, and help wash away metal debris generated during processing, keeping the working area clean.

Common FAQs about Brushing

Which CNC Machined Metal Parts Are Suitable for Brushed Surface Treatment?

Almost all CNC machined metal parts, including brass, stainless steel, aluminum alloys, etc., are suitable for brushed surface treatment. Due to the different physical and chemical properties of different metals, brushing processes and parameters need to be adjusted accordingly.

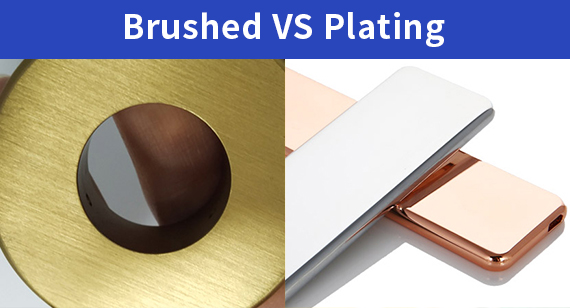

Is Brushed Finish Better than Electroplated Finish?

Brushed and electroplated finishes have their advantages and disadvantages, and it is not simple to declare one better than the other. Brushed finishes create unique textures and tactile feels on the metal surface through physical means without additional chemical treatment, making them environmentally friendly and relatively low-cost. They also increase the friction coefficient and corrosion resistance of the metal, suitable for applications requiring anti-slip or durability. On the other hand, electroplated finishes enhance the corrosion resistance and decorative appeal of the metal surface through a chemical deposition process, covering it with a layer of metal or alloy. However, electroplating can be more costly and may involve environmental issues. Therefore, choosing a surface treatment method should consider the specific needs and application scenarios of the product.

What Is the Difference Between Brushed Brass and Polished Brass?

Brushed brass and polished brass differ significantly in their surface treatment processes and final effects. Brushed brass creates fine grooves and textures on the surface through mechanical brushing, giving it a unique texture and visual effect. In contrast, polished brass removes surface roughness and scratches through polishing, making the surface smooth and mirror-like, with high gloss and reflectivity. Each has its own merits in aesthetics and physical properties, and users can choose based on their actual needs.

Conclusion

As an important material in CNC machined parts manufacturing, brushed brass stands out for its unique surface texture and tactile feel in various fields. By understanding the brushing process, influencing factors, process control, and custom techniques, we can better master the processing technology and quality control methods of brushed brass. Moreover, considering the pros and cons of brushed brass CNC machined parts and comparing them with other surface treatment methods helps us make more informed decisions. As a professional metal surface treatment expert, VMT is committed to providing high-quality brushed brass CNC machining services to meet the diverse needs of customers. In the future, we look forward to working with more customers to jointly promote the progress and development of CNC machining technology.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!