15 years one-stop China custom CNC machining parts factory

247 |

Published by VMT at Aug 09 2023 | Reading Time:About 3 minutes

247 |

Published by VMT at Aug 09 2023 | Reading Time:About 3 minutes

Brass, bronze, and red copper are three distinct copper-based alloys, each with unique characteristics and applications. These alloys play crucial roles in various industries and artistic endeavors due to their specific properties and versatility. Let's delve into the differences between Brass, bronze, and red copper, shedding light on their compositions, appearances, and uses.

Brass is an alloy composed primarily of copper and zinc, with the zinc content typically ranging from 15% to 40%. The addition of zinc imparts a golden-yellow hue to the alloy. Brass is valued for its workability, corrosion resistance, and aesthetic appeal, making it a popular choice for decorative items, musical instruments, and plumbing components.

Properties of Brass:

Bronze is an alloy primarily made up of copper and tin, although other elements like aluminum, manganese, and nickel can also be added. The exact composition of bronze can vary significantly, leading to a wide range of bronze alloys with varying properties. Bronze's reddish-brown color, strength, and durability have historically made it a favored material for sculptures, coins, and various industrial applications.

Properties of Bronze:

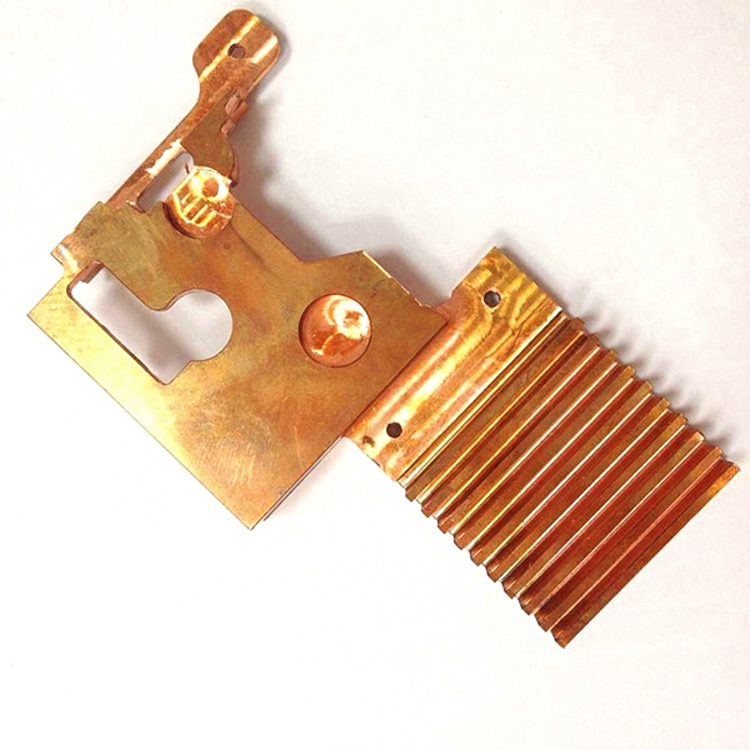

Red copper, also known as pure copper, is the elemental form of the metal. It consists of nearly 100% copper, often with trace amounts of impurities. Red copper is characterized by its distinct reddish-orange color and exceptional electrical and thermal conductivity. It's commonly used in electrical wiring, plumbing, and heat exchange applications where its conductivity and malleability are critical.

Properties of Copper:

Bronze, Brass, and red copper are distinct copper-based alloys, each with unique characteristics and applications. These alloys vary in composition, appearance, and properties, making them suitable for different purposes. Let's explore the differences between bronze, Brass, and red copper.

Composition:

Bronze: Bronze is primarily composed of copper and tin, with additional elements like aluminum, manganese, and nickel potentially added for specific properties. It typically contains 88-95% copper and 5-12% tin.

Brass: Brass consists of copper and zinc, with varying ratios. The zinc content ranges from 15% to 40%, affecting the alloy's properties and appearance.

Red Copper: Red copper, also known as pure copper, contains almost entirely copper, usually over 99%, with only trace impurities.

Color and Appearance:

Bronze: Bronze exhibits a characteristic reddish-brown color, although specific shades can vary based on alloy composition.

Brass: As the name suggests, Brass has a bright golden-yellow appearance due to its copper-zinc composition.

Red Copper: Red copper's hue is a distinct reddish-orange, a result of its elemental copper composition.

Properties and Uses:

Bronze: Bronze is valued for its strength, durability, and historical significance. It's often used in sculptures, coins, bearings, and marine components due to its load-bearing capabilities.

Brass: Brass combines corrosion resistance, malleability, and an attractive appearance. It's used in decorative items, musical instruments, and plumbing components.

Red Copper: Red copper's exceptional electrical and thermal conductivity makes it essential for electrical wiring, heat transfer systems, and plumbing applications.

Applications:

Bronze: Bronze finds use in artistic creations, historical artifacts, architectural elements, and various industrial components where strength and durability are required.

Brass: Brass is favored for decorative items, architectural details, and musical instruments, thanks to its corrosion resistance and aesthetic appeal.

Red Copper: Red copper's conductivity makes it indispensable in electrical systems, electronics, and heat exchangers.

Corrosion Resistance:

Bronze: The corrosion resistance of bronze depends on its composition, with some types offering excellent resistance, especially in marine environments.

Brass: Brass provides good corrosion resistance, making it suitable for outdoor and marine applications.

Red Copper: Red copper is susceptible to corrosion without protective coatings but can develop a green patina over time.

Conclusion:

In summary, bronze, Brass, and red copper are versatile copper-based alloys, each with distinct properties and applications. The choice between them depends on factors such as strength requirements, conductivity, corrosion resistance, and aesthetics. Understanding their differences empowers individuals in various industries to select the most appropriate alloy for their specific needs.

Bronze, Brass, and red copper come in various material grades, each with distinct characteristics that suit specific applications. Let's explore the material grades and their features for each of these copper-based alloys.

Bronze:

Phosphor Bronze (UNS C51000): This alloy contains copper, tin, and a small percentage of phosphorus. It offers excellent corrosion resistance and durability, making it suitable for springs, electrical connectors, and marine components.

Aluminum Bronze (UNS C61400): Aluminum bronze contains copper, aluminum, and sometimes other elements like iron and nickel. It has high strength, corrosion resistance, and wear resistance. It's commonly used in marine applications, heavy-duty equipment, and aerospace components.

Silicon Bronze (UNS C65500): Silicon bronze contains copper, silicon, and small amounts of other elements. It has good weldability, corrosion resistance, and is often used in architectural applications, sculptures, and artistic creations.

Brass:

Cartridge Brass (UNS C26000): Cartridge brass is a common type of Brass with excellent cold-working properties. It's used in ammunition casings, plumbing fittings, and musical instruments.

Naval Brass (UNS C46400): Naval brass is known for its corrosion resistance in marine environments. It contains copper, zinc, and sometimes tin, making it ideal for marine hardware, propellers, and valves.

Free-Cutting Brass (UNS C36000): Free-cutting brass has added lead, which enhances machinability. It's used for components requiring intricate machining, such as electrical connectors and fittings.

Red Copper:

Copper (UNS C11000): This is the purest form of copper, known for its excellent electrical and thermal conductivity. It's used in electrical wiring, heat exchangers, and plumbing systems.

Oxygen-Free Copper (UNS C10200): Oxygen-free copper has reduced oxygen content, enhancing its conductivity and reducing susceptibility to hydrogen embrittlement. It's used in high-conductivity applications like electrical conductors.

Deoxidized Copper (UNS C12200): Deoxidized copper is often used in brazing and soldering applications due to its minimized oxygen content, preventing oxidation during heating.

Each material grade within bronze, Brass, and red copper alloys offers specific advantages tailored to its intended applications. Understanding these grades and their characteristics enables engineers, manufacturers, and artisans to choose the most suitable alloy for their projects.

When it comes to selecting between bronze, Brass, and red copper, several factors, including pricing and specific requirements, play a crucial role. Let's explore the considerations for pricing and making the right choice among these copper-based alloys.

Pricing Considerations:

Bronze: The pricing of bronze varies depending on factors such as alloy composition, rarity of elements used, and market demand. Alloys with higher tin content tend to be more expensive due to the cost of tin. However, bronze's durability and historical significance often justify its cost for specific applications.

Brass: Brass is generally more cost-effective compared to bronze. The availability of copper and zinc, the primary components, contributes to its affordability. Brass's corrosion resistance, workability, and aesthetic appeal make it a practical choice for various applications.

Red Copper: Red copper's pricing is influenced by the purity of copper used and any processing it undergoes. It tends to be more cost-effective compared to alloys like bronze due to its elemental composition. Red copper's exceptional conductivity and malleability make it valuable for specific applications.

Choosing the Right Alloy:

Bronze: Choose bronze when strength, durability, and historical significance are essential. It's suitable for sculptures, bearings, marine components, and applications requiring load-bearing capabilities.

Brass: Opt for Brass when corrosion resistance, malleability, and an attractive appearance are important. It's used in decorative items, architectural details, and musical instruments.

Red Copper: Select red copper for applications requiring exceptional electrical and thermal conductivity. It's essential for electrical wiring, heat transfer systems, and plumbing.

Consider Your Project's Requirements:

Strength and Durability: If your project demands high strength and durability, consider bronze or specific brass alloys with added strength.

Corrosion Resistance: For outdoor or marine applications, Brass or certain bronze alloys with superior corrosion resistance might be the best choice.

Electrical and Thermal Conductivity: If your project involves electrical or heat transfer applications, red copper's outstanding conductivity makes it a prime candidate.

Budget and Aesthetics:

Budget: If cost is a significant factor, Brass or red copper might be more budget-friendly choices compared to bronze.

Aesthetics: If visual appeal is crucial, Brass's golden hue can resemble gold, making it an attractive option for decorative elements.

Ultimately, your choice between bronze, Brass, and red copper should align with your project's specific requirements, budget constraints, and desired aesthetics. Careful consideration of these factors will lead to the selection of the most suitable copper-based alloy for your needs.

Bronze, Brass, and red copper are versatile copper-based alloys that find a wide range of applications across various industries. Their unique properties make them valuable materials for diverse purposes. Let's explore the applications of each of these alloys:

Bronze Applications:

Sculptures and Art: Bronze's ability to hold intricate details and its reddish-brown color make it a favored choice for sculptures, statues, and artistic creations.

Coins and Commemorative Medals: Historically, bronze was used to mint coins due to its durability and distinct appearance. It's also employed for crafting commemorative medals.

Marine Components: Bronze's corrosion resistance makes it ideal for marine applications such as propellers, ship fittings, and underwater structures.

Bearings and Bushings: Bronze's self-lubricating properties make it suitable for bearings and bushings in machinery, reducing friction and wear.

Historical Restoration: Bronze's historical significance and durability make it a preferred material for restoring historical artifacts, architectural elements, and monuments.

Brass Applications:

Architectural Details: Brass's corrosion resistance and attractive golden-yellow color make it suitable for architectural accents, doorknobs, and hardware.

Musical Instruments: Many musical instruments, including trumpets, trombones, and saxophones, are crafted from Brass due to its resonance and workability.

Plumbing Components: Brass's corrosion resistance and malleability make it a common choice for plumbing fittings, valves, and connectors.

Decorative Items: Its vibrant color and versatility make Brass ideal for decorative items like lamps, picture frames, and ornaments.

Jewelry: In jewelry-making, Brass can be used as an affordable alternative to gold, offering a similar warm color.

Red Copper Applications:

Electrical Wiring: Red copper's exceptional electrical conductivity makes it an essential material for electrical wiring and power distribution systems.

Heat Transfer Systems: Red copper's high thermal conductivity makes it suitable for heat exchangers, radiators, and HVAC components.

Plumbing and Piping: Its malleability and corrosion resistance make red copper a preferred material for plumbing pipes and fittings.

Electronics: Red copper's conductivity and ability to dissipate heat are valuable in electronics, including circuit boards and heat sinks.

Roofing and Flashing: Red copper's durability and corrosion resistance make it a premium choice for roofing materials, flashing, and gutter systems.

These alloys cater to a wide array of industries and applications, showcasing their versatility and importance in modern manufacturing, artistry, and technology. The distinct properties of bronze, Brass, and red copper make them invaluable materials that contribute to various aspects of our lives.

Brass, bronze, and red copper are three copper-based alloys, each with its own unique set of advantages that make them valuable materials in various applications. Let's explore the benefits of each of these alloys:

Advantages of Brass:

Corrosion Resistance: Brass offers good corrosion resistance, making it suitable for outdoor and marine applications where exposure to moisture is a concern.

Aesthetic Appeal: Its bright golden-yellow color resembles gold, adding an attractive and luxurious touch to decorative items, architectural details, and jewelry.

Malleability: Brass's malleability allows for easy shaping and forming, making it suitable for intricate designs and artistic creations.

Workability: It is easy to machine, weld, and fabricate, making it a preferred choice for components that require precise manufacturing processes.

Affordability: Brass is often more cost-effective compared to other copper-based alloys, making it a practical choice for various projects.

Advantages of Bronze:

Strength and Durability: Bronze is known for its exceptional strength and durability, making it suitable for load-bearing applications and components subjected to mechanical stress.

Historical Significance: With a history dating back to ancient civilizations, bronze carries a sense of legacy and historical significance, making it favored for artistic and commemorative purposes.

Aesthetic Value: Its reddish-brown color and ability to hold intricate details make bronze a preferred material for sculptures, statues, and architectural accents.

Versatility: The addition of various alloying elements allows for the creation of bronze alloys tailored to specific applications, enhancing its versatility.

Longevity: Bronze's resistance to corrosion and wear ensures that items made from it can withstand the test of time, contributing to their longevity.

Advantages of Red Copper:

Exceptional Conductivity: Red copper's unparalleled electrical and thermal conductivity make it essential for applications in electrical systems, electronics, and heat transfer.

Malleability: Red copper is highly malleable, allowing for easy shaping and forming into intricate designs, especially in applications like plumbing and roofing.

Durability: Its resistance to corrosion and atmospheric degradation ensures its longevity, making it a reliable choice for various functional and structural components.

Heat Transfer: Red copper's excellent thermal conductivity makes it valuable for heat exchangers, radiators, and other heat transfer systems.

Sustainability: Its recyclability contributes to its sustainability, as red copper can be reused and repurposed, minimizing environmental impact.

Each of these alloys offers a unique combination of properties that cater to specific needs and applications. Whether it's the corrosion resistance of Brass, the strength of bronze, or the conductivity of red copper, these advantages make these alloys indispensable materials in a wide range of industries.

Do you know these metal materials? Do you know how to choose metal materials? VMT has professional material experts and material testing rooms to provide you with competitive advantages and select the most suitable project materials.

We also provide one-stop CNC machining prototyping services, including CNC machining, CNC turning, Swiss CNC machining, 5-axis CNC machining, die-casting, extrusion, etc. Contact us now, send your design files to our email: inquiry@vimetal.com.cn, and get your quotation immediately. Let us start your project!

Curious about the distinctions between brass, bronze, and copper? Here are some frequently asked questions that shed light on these copper-based alloys:

1. What are the main differences between brass, bronze, and copper?

Brass is an alloy of copper and zinc, often with a yellow-gold color. Bronze, on the other hand, is a copper-tin alloy, with a reddish-brown appearance. Copper is the pure elemental form of the metal, distinguished by its characteristic reddish-orange hue.

2. What are the key applications for each alloy?

Brass is used in decorative items, plumbing fittings, and musical instruments. Bronze finds its place in sculptures, marine components, and historical artifacts. Copper is vital for electrical wiring, heat exchangers, and plumbing systems.

3. Which alloy is best for artistic creations?

Bronze's strength, durability, and ability to hold intricate details make it a favored choice for sculptures and artistic projects.

4. Are these alloys environmentally friendly?

Yes, these alloys are highly recyclable, contributing to their sustainability and minimizing their impact on the environment.

5. Can these alloys be combined in a single project?

Absolutely, projects often involve using multiple alloys based on their specific strengths and characteristics.

6. Are there health considerations when working with these alloys?

Safety precautions should be taken when working with any metal alloys, especially considering potential impurities and coatings.

7. Are these alloys suitable for outdoor applications?

Yes, brass and specific bronze alloys are corrosion-resistant and can be used in outdoor environments, especially when proper maintenance is applied.

8. Can these alloys be alloyed with other metals?

Yes, brass and bronze can be further alloyed with other elements to achieve specific properties tailored to different applications.

9. Which alloy is best for applications requiring conductivity?

Red copper's exceptional electrical and thermal conductivity makes it an optimal choice for applications where conductivity is crucial.

10. Can these alloys be used in modern industries?

Absolutely, these alloys have a wide range of applications in industries including manufacturing, construction, electronics, and art.

Embrace the unique qualities of brass, bronze, and copper, and choose the alloy that best fits your project's needs. Each alloy offers a distinctive set of properties and advantages that cater to a variety of applications and industries.

11. Brass and Bronze: Which is More Affordable?

Between brass and bronze, brass is generally more affordable compared to bronze. Brass is primarily composed of copper and zinc, which are widely available and cost-effective materials. The zinc content in brass contributes to its corrosion resistance and malleability.

On the other hand, bronze is an alloy of copper and tin, often with additional elements like aluminum, manganese, or nickel. The inclusion of tin, which tends to be pricier than zinc, can contribute to the relatively higher cost of bronze compared to brass.

12. Bronze, Brass, and Copper: Which is Magnetic?

Among bronze, brass, and copper, none of these copper-based alloys are inherently magnetic. Copper and its alloys, including bronze and brass, are generally considered non-magnetic materials. This non-magnetic property is due to the absence of significant magnetic elements in their compositions.

While some variations of these alloys may contain trace amounts of magnetic elements, such as iron, these amounts are usually negligible and do not result in significant magnetic properties. Therefore, in most practical applications, bronze, brass, and copper are not considered magnetic materials.