15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

240 |

Published by VMT at Oct 19 2021

240 |

Published by VMT at Oct 19 2021

Centerless Grinding has a long history. As early as the Stone Age, humans began to use abrasives to grind and process various stones, animal bones, shells and other tools used for hunting and living. Centerless grinding is a high-productivity precision machining method, which is an outer diameter grinding process.

Centerless grinding has attracted people’s attention because it has more advantages than other processes in other industries, such as: fast processing (time saving), smaller loading time (about 3 seconds per part, saving time again), It can process multiple diameters and a huge number of parts. This article mainly describes the relevant knowledge of centerless grinder.

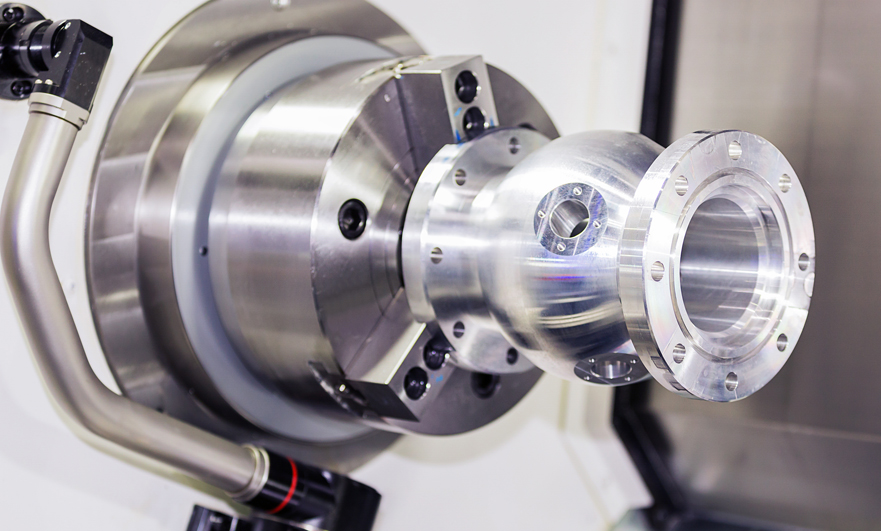

What is centerless grinding?

Centerless grinding is also called OD grinding. Centerless grinding is a very important machining method for machining cylindrical rod workpieces. This machining method does not require clamping and positioning of the workpiece. Instead, it uses guide wheels, pallets and grinding wheels. Guided rotation for grinding, the guide wheel drives the cylindrical workpiece to rotate on the shim, rotating in the same direction and at different speeds, and the material is removed by the grinding wheel.

Advantages of Centerless Grinding:

1. Higher efficiency and accuracy

The automatic loading and unloading system shortens the time between manual handling of the workpiece and the starting point of production. The docking system has been integrated into the process instead of treating them as separate operations.

2. Cost saving

Loading system automation can save your business costs. Less manpower required during storage and handling. Fewer people means less labor costs.

3. Improve safety in the workplace

The automatic loading system can be said to have doubled the safety of the workplace. These machines can be installed on many safety devices to reduce collisions and to a large extent reduce the occurrence of manual errors.

4. Wide processing range

Since there is no additional pressure on both ends of the workpiece, the centerless grinder is very suitable for processing fragile workpieces and fragile materials. By supporting the workpiece linearly, it is also possible to grind soft or fragile materials because these machines operate through a low-tension process. There is no need to prepare a fixed workpiece for the grinder, so as to eliminate the failure caused by the fixation. In addition, smaller machines can handle long workpieces.

Application of Centerless Grinding

Parts machined by centerless grinding are used in many industries such as the automotive industry, aerospace, bearings, consumer products, and so on. Machining parts include shafts, balls, bearings, bolts, bushings, camshafts, carbide rods, compressor shafts, forming rollers, cylinders, drill bits, gear shafts, etc.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!