15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

816 |

Published by VMT at Nov 01 2024 | Reading Time:About 2 minutes

816 |

Published by VMT at Nov 01 2024 | Reading Time:About 2 minutes

Are you looking for ways to strengthen metal components without adding weight? Sheet metal hemming is the answer. This technique improves product quality, ensuring durability and a professional finish.

Sheet metal hemming is a manufacturing process that folds metal edges to reinforce strength and safety. It reduces sharpness and enhances aesthetics, often used in automotive, aerospace, and consumer goods industries.

Let’s explore the complete process, tools, benefits, and challenges of sheet metal hemming.

Sheet metal hemming involves folding the edge of a metal sheet back onto itself. The purpose is to smoothen sharp edges and increase strength. It's widely used in sectors requiring high precision and durable components, such as automotive body panels, electronics, and appliance manufacturing. By combining functionality with aesthetics, hemming ensures product reliability and customer satisfaction.

Sheet metal hemming offers multiple advantages. First, it prevents users from cutting themselves on sharp metal edges. Second, it increases material rigidity without needing additional parts, which reduces manufacturing costs. Third, hemmed components align seamlessly with mating parts, improving assembly quality. Industries like automotive and consumer electronics rely heavily on hemming to maintain performance while reducing defects.

Tools Required

Effective hemming relies on specialized tools:

Sheet Metal: Thin, malleable metal sheets made from aluminum, steel, or copper.

Hemming Tools or Press Brakes: Machines to bend and fold metal sheets accurately.

Flattening Tools: Equipment such as rollers or pliers to compress hems evenly.

Finishing Tools: Hammers or sandpaper to smoothen the folded metal edge.

Quality Inspection Tools: Micrometers and calipers ensure hem precision.

Material Selection

Choosing the right material is crucial for effective hemming:

Stainless Steel: Corrosion-resistant and suitable for automotive parts.

Cold Rolled Steel: Ideal for structural applications due to its strength.

Aluminum: Lightweight, making it a favorite in aerospace and electronics.

Copper and Brass: Used for decorative purposes due to their visual appeal.

Design and Preparation

Before hemming, proper planning ensures efficiency:

Marking Bend Lines: Precision is critical; marking lines guides the bend for accuracy.

Setting Up the Machine: Operators need to calibrate press brakes to match the material thickness.

Pre-Hemming Procedures: Some metals may require heat treatment to avoid cracking.

Hemming Procedures

Hemming methods vary depending on the application and equipment available:

Traditional Die Hemming: Uses a press die to bend the sheet edge. Suitable for thick materials.

Roller Hemming: Ideal for continuous production lines, where rollers fold edges gradually.

Initial Bend

The first step is forming a 90-degree bend along the marked line. This initial bend establishes the path for the hem, ensuring alignment during further processing.

Forming the Hem

The folded edge is flattened using rollers or a press brake. Careful control of pressure prevents metal deformation, ensuring a consistent fold.

Finishing and Inspection

Post-hem, components undergo finishing processes, such as polishing or coating, to enhance their appearance. Quality control checks ensure that the hem meets size and strength specifications.

Flat or Closed Hem: Common in automotive manufacturing, where the edge is folded flat against the sheet.

Open Hem: Leaves a small gap, often used in ductwork for flexibility.

Teardrop Hem: Creates a curved, aesthetically pleasing edge.

Rope Hem: Used for reinforced strength in heavy-duty applications.

Hemming with Sealant: Adds adhesive between layers for waterproofing or insulation.

Die Hemming Process: Suitable for heavy sheets, providing precise results but requiring expensive dies.

Rolling Hemming Process: Cost-effective for mass production, although it requires constant machine calibration.

Increased Strength and Stiffness: Reinforces structural integrity without added weight.

Enhanced Appearance: Smooth, rounded edges offer an aesthetically pleasing finish.

Better Functionality: Prevents sharp edges and improves assembly alignment.

More Resistance to Damage: Hemmed edges reduce the risk of dents or fractures.

Time-Consuming: Complex hems require multiple stages of processing.

Requires Skilled Labor: Precision is essential, demanding experienced operators.

Potential Deformation: Incorrect pressure can warp or crack the sheet metal.

Material Selection: Choose metals suitable for the intended use and hemming process.

Accurate Preparation and Measurement: Ensure bend lines are marked precisely.

Use of Appropriate Tools: Different hemming processes require specific equipment.

Proper Alignment: Misalignment can compromise the hem’s strength and appearance.

Quality Control: Regular inspections prevent defects.

Progressive Bending Techniques: Minimize stress by bending in stages.

Sheet metal hemming is integral to the production of car body panels, HVAC systems, appliance casings, and electronic enclosures. It offers an ideal balance of strength and design, making it indispensable across industries.

Automotive Industry: Hemming is frequently used for body panels, door frames, and structural components, where strength and aesthetics are critical.

Appliance Manufacturing: Hemmed edges provide a polished look for appliances such as refrigerators, washing machines, and ovens.

HVAC Systems: Hemming is used in the manufacturing of ductwork and other HVAC components to ensure a clean and functional design.

Hemming is often compared to other metal forming processes, each offering unique advantages and applications. Understanding these differences can help manufacturers select the best method for their needs.

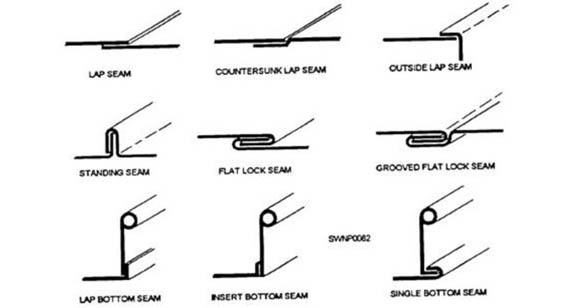

Sheet Metal Hemming vs. Seaming: While hemming folds the edge, seaming joins two metal sheets together. While both processes involve joining two pieces of metal, hemming focuses on creating a finished edge, whereas seaming typically involves overlapping edges without the need for a clean finish.

Sheet Metal Bending vs. Sheet Metal Hemming: Bending alters the sheet's shape, whereas hemming reinforces its edge. Bending involves altering the shape of the metal sheet without necessarily creating a finished edge. In contrast, hemming specifically addresses the edges of the metal for enhanced strength and appearance.

At VMT, we specialize in custom CNC machining, including sheet metal CNC machining parts. With advanced press brakes and rolling systems, our factory delivers high-precision hemming for CNC prototype machining and batch production. Contact us for customized solutions at VMT Sheet Metal.

Sheet metal hemming is a vital process in metal fabrication, providing enhanced strength, aesthetics, and functionality to metal components. By understanding the technology, techniques, and applications of hemming, manufacturers can make informed decisions that lead to high-quality results. Whether you are in the automotive industry, appliance manufacturing, or any other sector, incorporating sheet metal hemming into your processes can significantly improve the quality and performance of your products.

Sheet metal hemming ensures product durability, safety, and functionality across industries. With precise tools and techniques, manufacturers can achieve professional-quality results efficiently.

How to make a hem on sheet metal?

Mark the bend lines, apply an initial bend, and use a press or roller to flatten the edge.

What are the common applications for sheet metal hemming?

Hemming is used in automotive panels, HVAC systems, and electronic enclosures.

How does a sheet metal hem differ from a seam?

A hem folds the edge, while a seam joins two sheets.

Is sheet metal hemming expensive?

It depends on material, labor, and equipment costs.

What is the allowance for sheet metal hemming?

Typically, 2-3 times the material thickness is allowed for hemming.

What is the minimum hemming length of sheet metal?

The minimum length depends on the material but usually measures around 5 mm.

What is the recommended length of sheet metal hemming?

Optimal hem lengths ensure alignment and prevent buckling, generally 10 mm or more.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!