15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

141 |

Published by VMT at Jan 29 2022

141 |

Published by VMT at Jan 29 2022

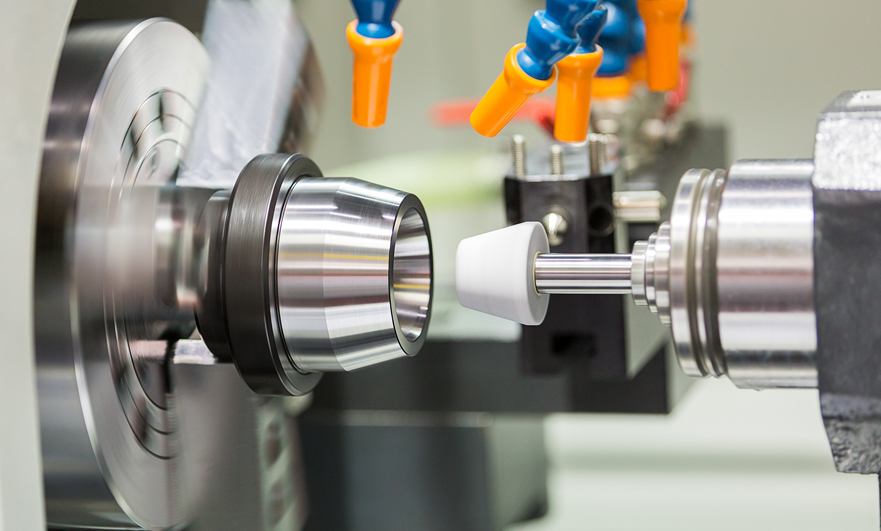

The grinding of super-hard abrasive micro-powder grinding wheel can be carried out on CNC precision parts machining grinding machine. For precision grinding, it should be carried out on the corresponding CNC precision parts machining grinding machine.

Abrasives are the particles in the grinding wheel that are responsible for grinding and cutting, and are usually sharp and hard. The earliest abrasives can be divided into natural abrasives and artificial abrasives according to their origin. However, natural abrasives are replaced by artificial abrasives in many applications due to their unstable properties.

Definition of superabrasive

The term superabrasive comes from a polycrystalline diamond (PCD) material for cutting tools developed by General Electric (GE) in the 1970s. At the time, this hard and brittle material was considered a major improvement in cutting tools.

At present, diamond and cubic boron nitride (CBN) are generally used as superabrasive particles in industry, while WA (white alumina), A (brown alumina), GC (green silicon carbide), etc. are called ordinary abrasive particles. In terms of hardness, diamond is the highest grade of silicon carbide, while CBN is the highest grade of alumina.

The main reason for superabrasives to dominate the abrasives industry is that in order to improve the performance of key components, the manufacturing industry continues to improve the structure of metal alloy materials, making these materials increasingly difficult.

In order to polish another material, one material has to be harder than it is, so general abrasives get progressively weaker and harder superabrasives stand out.

Grinders must have sufficient stiffness, high stability and low vibration. The stiffness of the machine tool will affect the quality and anti-vibration performance of the abrasive socks, which in turn affects the durability and service life of the superabrasive wheel, as well as the quality of the grinding process. Generally, the stiffness of ordinary grinders is required to be increased by about 50%.

When grinding superabrasive wheels, lower vibration is required. The machine tool should be installed on an anti-vibration foundation, and corresponding anti-vibration and vibration isolation measures should be taken. For example, grinding wheels should be finely trimmed and balanced, and anti-vibration pads should be added to the contact between the machine and the ground.

The grinder should have high precision. In terms of the rotation accuracy of the grinding wheel spindle, the radial runout should be less than 0.001 mm, and the axial runout should be less than 0.005 mm. The main shaft bearing should be a dynamic pressure bearing or a dynamic and static combined bearing, and a hydrostatic bearing can also be used. Ensure the machining accuracy required for precision CNC machining grinding.

It requires high precision feed system, uniform and stable speed, wide speed range, high speed, to ensure productivity requirements, and low speed to ensure grinding size, shape accuracy and surface roughness requirements. In general, the minimum longitudinal feed rate should be 0.1m/min or less, and the minimum transverse feed (grinding depth) should be 0.001~0.0005 mm/8t (st^single stroke). For the grinding of micro powder grinding wheel, the horizontal feed rate of the grinding machine should be considered to match the size of the abrasive grains.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!