15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

123 |

Published by VMT at Jan 31 2022

123 |

Published by VMT at Jan 31 2022

What is aluminum profile?

As the name suggests, aluminum profiles are extruded profiles of aluminum profiles.

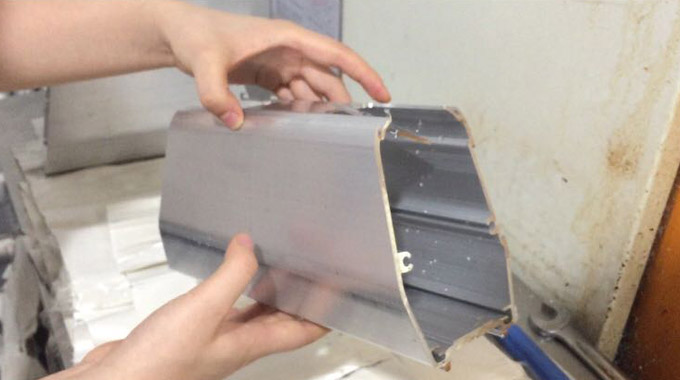

The process of extruding aluminum profiles can be understood as an indenter, which pushes the aluminum alloy material through a specific die to extrude the aluminum profile from the die opening.

The significance of industrial aluminum profiles

Aluminum profile system, also known as industrial aluminum profile, industrial aluminum alloy profile, is an alloy material with aluminum as the main component. But the proportion of the added amount is different. The mechanical properties and application fields of the industrial aluminum profiles produced are also different. The implementation standard is GB/T 5237-2008. Industrial aluminum profiles generally refer to various aluminum profiles other than building doors and windows, curtain walls, interior and exterior decoration, and building structures.

Industrial aluminum alloy profiles are extremely versatile and widely used, and have the advantages of environmental protection, easy disassembly and assembly, saving time and money, etc. There are many kinds of industrial aluminum profiles with complete specifications, which are suitable for all kinds of machinery and equipment. No need for welding, convenient size adjustment, convenient structure adjustment. Tight dimensional tolerance requirements and high surface finish requirements. The assembly work is convenient and fast, and the production efficiency is high. The surface is anodized, anti-corrosion, no spray, beautiful, and improves the added value of the product. Aluminum profile CNC machining parts.

Applicable to: production assembly line, assembly line operation table, office partition, screen, industrial fence, various frames, display racks, shelves, mechanical dust cover, etc.

After oxidation treatment, the surface of industrial aluminum profiles has a very beautiful appearance. It resists dirt and once oiled and grime is applied, it is easy to clean. When assembling into products, use profiles of different specifications according to different bearing weights, and use matching aluminum profile accessories. No welding is required, it is more environmentally friendly, and it is very convenient to install, disassemble, carry and move.

1. Industrial aluminum profile is a new type of product. In the field of industrial manufacturing, it is mainly manifested in automated machinery and equipment, assembly line conveyor belts, elevators, dispensing machines, testing equipment, shelves, electronic machinery industry and clean rooms.

2. The production line is a large-scale conveying equipment. The aluminum profile can be reasonably planned in the area to play a protective role. We often call it aluminum profile guardrail, aluminum profile protective cover, etc.

3. The warehouse department of the factory is also essential, such as material racks, mobile trolleys, stair treads, etc. are also made of industrial aluminum profiles.

4. Aluminum profiles have the advantages of light weight and corrosion resistance, and are especially suitable for medical equipment such as stretch frames, medical equipment, and medical beds.

5. Aluminum profiles are light in weight and strong in bearing capacity. The special profile structure is convenient for the installation and connection of electrical equipment, and it also has its own position in the field of automobile manufacturing. These five fields summarize the application range of industrial aluminum profiles, of which the most extensive is undoubtedly the aluminum profile frame, which has a variety of assembly forms and is generally designed according to customer requirements.

Compared with iron and stainless steel, extruded aluminum profiles have the following advantages:

1. Non-toxic and environmentally friendly, aluminum is highly recyclable.

2. The extrusion process has low cost, simple process and convenient installation and disassembly.

3. A wide range of aluminum profile products, excellent processing performance of aluminum profiles, flexible production (customized aluminum profiles).

4. Various surface treatment effects (such as electrophoretic coating, powder coated abrasive cloth, etc.). to meet different needs.

5. Strong corrosion resistance, extruded aluminum profiles are more durable. Aluminum exhibits excellent corrosion resistance under most environmental conditions.

electrical frame

Aluminum profiles are becoming more and more popular as frames for household appliances. These frames are usually aluminium extruded profiles. Some examples are refrigerator frames and TV frames.

light box frame

The most representative of this type is the open-type ultra-thin light box frame aluminum profile.

The advantage of this aluminum frame is that the billboard can be easily opened and replaced during installation.

some other frames

Aluminum frame for some glass products, aluminum frame with heat dissipation function, such as poster frame, whiteboard frame, blackboard frame, etc.

All aluminum furniture

In this era of diversified development, all-aluminum furniture home customization is becoming more and more popular.

The use of aluminum alloy profiles to customize cabinets, etc., has the advantages of being beautiful, durable and recyclable.

This material can be reused

Since mechanical parts using industrial aluminum profiles do not require heat welding during the entire production process, the parts are easily disassembled and all materials and accessories can be reused. In contrast, traditional materials are rarely reused due to high cutting deformation and disassembly costs.

save time

Due to the simple production process, higher labor costs are saved. Especially the rework caused by production errors saves several times the time compared to traditional materials.

High precision

Since the CNC machining manufacturing process does not undergo thermal welding, the material is not deformed and the assembly precision is high. Traditional thermal welding materials are bound to deform, which affects the final assembly accuracy.

nice looking

The appearance of industrial aluminum profile equipment is more modern, and its unique anodized film is more stable than existing aluminum plating methods.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!