15 years one-stop China custom CNC machining parts factory

10600 |

Published by VMT at Sep 30 2021

10600 |

Published by VMT at Sep 30 2021

Introduction

In the world of precision CNC machining, ISO 2768 stands as a crucial standard for dimensional tolerances. This comprehensive guide will delve into the intricacies of ISO 2768, its significance in CNC machining.

Precision CNC machining is a highly advanced manufacturing process that utilizes computer numerical control (CNC) machines to produce precise and intricate components. In this article, we will explore the significance of ISO 2768 dimensional tolerance chart in precision CNC machining parts.

The most important thing in the design and manufacture of each high-quality CNC machined part is the tolerance. How to clarify the tolerance value of a specific CNC machined part? This is inseparable from the help of ISO international standards. This article will use ISO 2768 standard and ISO 2768 tolerance chart to introduce you relevant knowledge.

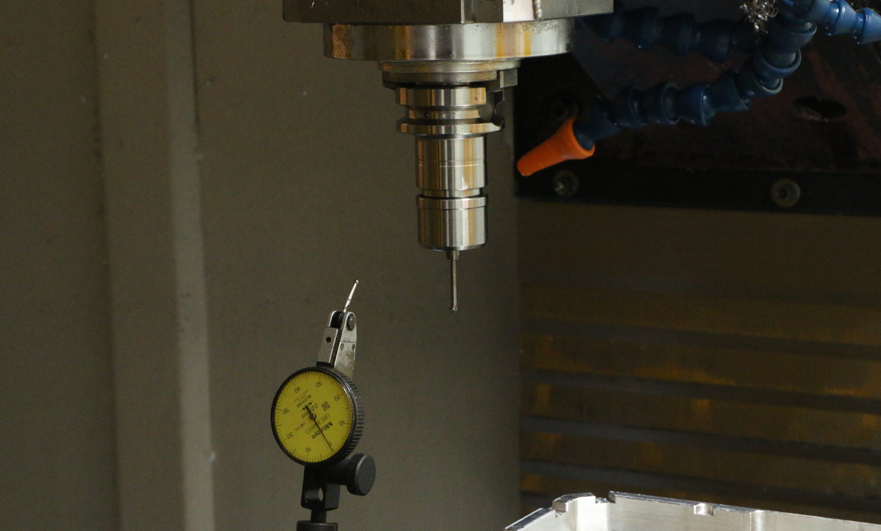

What is Precision CNC Machining?

Precision CNC machining is a manufacturing technique that employs computer-controlled machines to remove material from a workpiece, resulting in the creation of complex and accurate components. This process involves the use of various tools such as mills, lathes, and grinders, all of which are controlled by pre-programmed computer software to achieve precise and intricate designs.

What is the ISO 2768 tolerance standard?

The ISO 2768 tolerance standard is an international tolerance standard specified by the ISO International Organization for Standardization. It is mainly divided into one part and two parts. The international standard ISO2768-1 was drafted by the ISO/TC3 "Limits and Coordination" Technical Committee. ISO 2768-Part One (First Edition) and ISO 2768-Part Two (1989 Edition) replace ISO 2768 (1973 Edition) together.

It provides guidance for general tolerances for linear and angular dimensions for which there is no individual tolerance indication. It provides a framework for specifying acceptable variations in dimension and geometry of machined parts, ensuring their functionality and interchangeability.

The Significance of ISO 2768 Dimensional Tolerance Chart

In precision CNC machining, dimensional tolerance plays a crucial role in ensuring the accuracy and functionality of machined parts. ISO 2768 is an international standard that provides guidelines for general tolerances of linear and angular dimensions without individual tolerance indications. This standard helps manufacturers maintain consistency in the dimensions of machined parts, ensuring compatibility and interchangeability.

Key Elements of ISO 2768 Standard

The ISO 2768 standard comprises several key elements that define its application and usage. These elements include fundamental tolerances, deviations, and surface roughness, which collectively help in establishing the permissible limits of variation for machined parts.

Types of Dimensional Tolerances

ISO 2768 defines various types of dimensional tolerances, such as general tolerances for linear and angular dimensions, form tolerances, and orientation tolerances. Each type serves a specific purpose in determining the allowable variations in size, shape, and orientation of machined components.

Interpreting ISO 2768 Tolerance Codes

ISO 2768 employs a series of tolerance codes that represent different levels of tolerance precision. These codes provide a standardized system for specifying tolerances, facilitating clear communication between designers, manufacturers, and inspectors.

Importance of ISO 2768 in CNC Machining

ISO 2768 plays a critical role in CNC machining by ensuring consistent and accurate production of machined parts. By adhering to the specified tolerances, CNC machines can achieve the desired precision, functionality, and compatibility of components.

Benefits of Using ISO 2768 Dimensional Tolerances

The utilization of ISO 2768 dimensional tolerances offers several benefits for manufacturers and end-users. These advantages include improved interchangeability, enhanced quality control, reduced production costs, and increased efficiency in CNC machining processes.

Understanding Dimensional Tolerance

Dimensional tolerance refers to the allowable variation in the size and geometry of a machined part. It specifies the permissible difference between the desired dimensions and the actual dimensions of the component. The ISO 2768 standard provides a range of tolerances based on the size and complexity of the part, enabling manufacturers to control the quality and precision of the final product.

ISO2768 consists of the following parts under the main heading "General Tolerance":

Part 1: Tolerances for linear and angular dimensions without tolerances, divided into 4 levels (high precision f medium m rough c very rough v)

Part 2: The geometric tolerances of elements without tolerances are divided into 3 different grades of shape and position tolerance (H, K, L)

What do the letters in ISO 2768-mK, ISO 2768-fH, etc. mean?

It is a tolerance standard carried out by the grade of m in the first part and K in the second part. It is usually implemented by the m-level specified in ISO 2768-1 and the K-level tolerance level specified in ISO 2768-2. The same is true for ISO 2768–fH, ISO 2768–ck, ISO 2768–vL, etc.

How to choose tolerance standard?

Regarding this issue, you can determine the tolerance level you need based on your machining needs and the manufacturer's production capacity. Normally, ISO 2768-fH is the ideal choice for CNC machining.

ISO 2768-1 range (general tolerances for linear and angular dimensions)

Suitable for the following sizes:

a) Linear dimensions (such as external dimensions, internal dimensions, step length, diameter, radius, distance, external radius and the height of the chamfer of the hemming);

b) Angular dimensions, including angular dimensions that are not usually indicated, such as right angles (90°). Unless referring to ISO 2768-2 or the angle of a unified polygon;

c) Linear and angular dimensions produced by processing assembled parts.

Not applicable to the following sizes:

a) Refer to the linear and angular dimensions covered by other general tolerance standards;

b) Auxiliary dimensions marked in brackets;

c) The theoretically accurate size shown in the rectangular frame.

ISO 2768-2 tolerance range (geometric tolerance of elements without tolerance)

Suitable for the following sizes:

a) Linear dimensions (such as outer dimensions, inner dimensions, step dimensions, diameter, radius, distance, rounding radius and chamfer height).

b) Angular dimensions, including angle dimensions for which no angle values are usually stated, such as right angles (90) (except for the angles specified in the second part of ISO 2768) or equal polygonal angles.

c) Linear and angular dimensions of the machined assembly.

Not applicable to the following sizes:

a) Linear and angular dimensions of other general CNC machining parts tolerance standard sand

b) Reference size in brackets

c) The theoretical correct size of the rectangular frame

Benefits of Using ISO 2768 Dimensional Tolerances

The utilization of ISO 2768 dimensional tolerances offers several benefits for manufacturers and end-users. These advantages include improved interchangeability, enhanced quality control, reduced production costs, and increased efficiency in CNC machining processes.

Factors Affecting Tolerance Selection

When selecting tolerances according to ISO 2768, several factors come into play, such as the function and purpose of the component, manufacturing capabilities, material properties, and customer requirements. Careful consideration of these factors ensures the appropriate tolerance selection for a given application.

Practical Applications of ISO 2768 in CNC Machining

ISO 2768 finds practical applications in various industries where precision machining is essential. These applications span sectors such as automotive, aerospace, electronics, medical devices, and many more. ISO 2768 enables manufacturers to produce high-quality components that meet the desired specifications and performance requirements.

Challenges and Limitations of ISO 2768

While ISO 2768 provides a standardized framework for dimensional tolerances, it also presents certain challenges and limitations. These include the need for clear communication, the complexity of interpreting tolerance codes, and the consideration of additional factors like material shrinkage and environmental conditions.

ISO2768 -2 tolerance standard table

Table 1 – Linear Dimensions

| Permissible deviations in mm for ranges in nominal lengths | Tolerance Class Designation (Description) | |||

| f (fine) | m (Intermediate) | c (coarse) | v (extremely thick) | |

| 0.5 up to 3 | ± 0.05 | ± 0.10 | ± 0.2 | – |

| over 3 up to 6 | ± 0.05 | ± 0.10 | ± 0.3 | ± 0.50 |

| over 6 up to 30 | ± 0.10 | ± 0.20 | ± 0.50 | ± 1.00 |

| over 30 up to 120 | ± 0.15 | ± 0.30 | ± 0.80 | ± 1.50 |

| over 120 up to 400 | ± 0.20 | ± 0.50 | ± 1.20 | ± 2.50 |

| over 400 up to 1000 | ± 0.30 | ± 0.80 | ± 2.00 | ± 4.00 |

| over 1000 up to 2000 | ± 0.50 | ± 1.20 | ± 3.00 | ± 6.00 |

| over 2000 up to 4000 | – | ± 2.00 | ± 4.00 | ± 8.00 |

Table 2 – External Radii and Chamfer Heights

| Tolerance Class Designation (Description) | ||||

| Permissible deviations in mm for ranges in nominal lengths | f (fine) | m (Intermediate) | c (coarse) | v (extremely thick) |

| 0.5 up to 3 | ± 0.2 | ± 0.2 | ± 0.4 | ±0.4 |

| over 3 up to 6 | ± 0.5 | ± 0.5 | ± 0.1 | ± 0.1 |

| over 6 up to 30 | ± 1.0 | ± 1.0 | ± 2.0 | ± 2.0 |

Table 3 – Angular Dimensions

| Permissible deviations in mm for ranges in nominal lengths | Tolerance Class Designation (Description) | |||

| f (fine) | m (Intermediate) | c (coarse) | v (extremely thick) | |

| up to 10 | ±1º | ±1º | ±1º30′ | ±3º |

| over 10 up to 50 | ±0º30′ | ±0º30′ | ±1º | ±2º |

| over 50 up to 120 | ±0º20′ | ±0º20′ | ±0º30′ | ±1º |

| over 120 up to 400 | ±0º10′ | ±0º10′ | ±0º15′ | ±0º30′ |

| over 400 | ±0º5′ | ±0º5′ | ±0º10′ | ±0º20′ |

#2 General Tolerances ISO 2768-2

Table 4 – General Tolerances on Straightness and Flatness

| Ranges of nominal lengths in mm | Tolerance Class | ||

| H | K | L | |

| up to 10 | 0.02 | 0.05 | 0.1 |

| above 10 to 30 | 0.05 | 0.1 | 0.2 |

| above 30 to 100 | 0.1 | 0.2 | 0.4 |

| above 100 to 300 | 0.2 | 0.4 | 0.8 |

| above 300 to 1000 | 0.3 | 0.6 | 1.2 |

| above 1000 to 3000 | 0.4 | 0.8 | 1.6 |

Table 5 – General Tolerances on Perpendicularity

| Ranges of nominal lengths in mm | Tolerance Class | ||

| H | K | L | |

| up to 100 | 0.2 | 0.4 | 0.6 |

| above 100 to 300 | 0.3 | 0.6 | 1.0 |

| above 300 to 1000 | 0.5 | 0.8 | 1.5 |

| above 1000 to 3000 | 0.5 | 1.0 | 2.0 |

Table 6 – General Tolerances on Symmetry

| Ranges of nominal lengths in mm | Tolerance Class | ||

| H | K | L | |

| up to 100 | 0.5 | 0.6 | 0.6 |

| above 100 to 300 | 0.5 | 0.6 | 1.0 |

| above 300 to 1000 | 0.5 | 0.8 | 1.5 |

| above 1000 to 3000 | 0.5 | 1.0 | 2.0 |

Table 7 – General Tolerances on Circular Run-Out

| Ranges of nominal lengths in mm | Tolerance Class | ||

| H | K | L | |

| 0.1 | 0.2 | 0.5 | |