15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

1347 |

Published by VMT at Sep 29 2021

1347 |

Published by VMT at Sep 29 2021

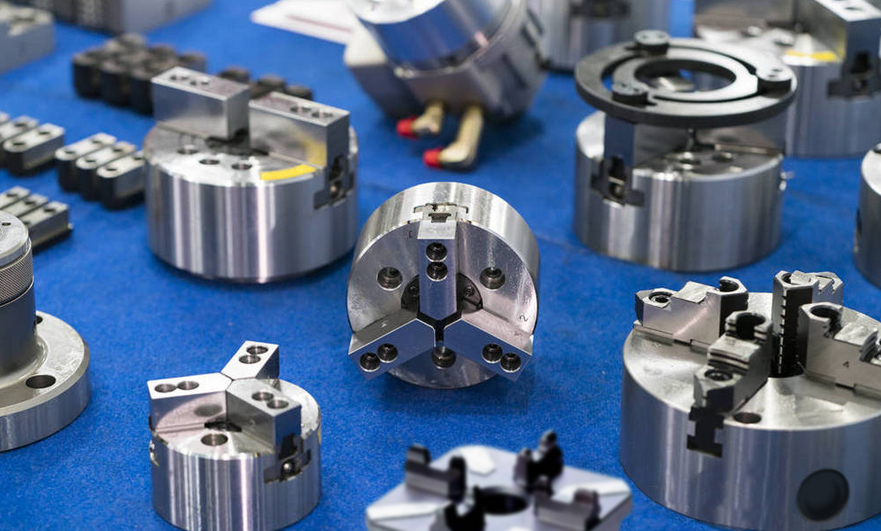

The chuck is an important part of the turning process. As a clamping device, it has the function of fixing and safely clamping the workpiece. The chuck of the lathe has diversity to ensure that the material of the CNC turning parts can be kept stable and precise. This article will focus on the knowledge of the three-jaw chuck.

What is a three-jaw chuck?

The chuck is a fixture that clamps the material of CNC turning parts in a specific position. It is widely used in CNC machining factories. The three-jaw chuck uses the radial movement of three movable jaws evenly distributed on the chuck body to clamp the workpiece And positioning to the machine tool attachment. The three-jaw chuck also refers to the general-purpose chuck. When very fast, reasonable and accurate centering is required, this type is most suitable for clamping round and hexagonal CNC turning parts.

Three-jaw chuck structure

1. Manual three-jaw chuck structure

The three-jaw chuck is composed of a claw body, a small bevel gear, a large bevel gear (the other end is a plane thread) and three jaws. The three jaws are matched with the same thread as the plane thread, and the three jaws are uniformly distributed at 120 in the guide groove in the jaw plate body. The taper hole of the claw body is matched with the outer taper surface of the front end of the lathe spindle, which plays a centering role, and transmits torque through the key. Finally, the chuck body is locked on the spindle with a nut.

2. Power three-jaw chuck structure

The power chuck is a self-centering chuck, which can be combined with different power devices (cylinder, oil cylinder or motor) to form a pneumatic chuck, a hydraulic chuck or an electric chuck. The air cylinder or oil cylinder is installed at the back end of the spindle of the machine tool, and the tie rod or tube passing through the spindle hole is used to push and pull the wedge sleeve in the chuck body at the front end of the spindle. This kind of chuck has rapid movement and small movement of the jaws, which is suitable for the production of large quantities of CNC turning parts.

How does the three-jaw chuck work?

Three-jaw chuck All the jaws of the three-jaw chuck are installed on a scroll, which uses the chuck wrench to rotate any of the three umbrella teeth on the circumference, thereby driving the plane thread to rotate and driving the three jaws Move together to play the role of self-centering and clamping parts. Three-jaw chucks are commonly used in lathes and indexing heads.

Chuck type

| Chuck type | Features | Application |

| Zhongshi Power Chuck | 1. The force of the wedge sleeve is directly transmitted to the claw guide area, so in the process of axial driving force transmission to the claw, 2. The friction loss is small 3. High radial and axial accuracy 4. High clamping force 5. High speed 6. Long jaw guide groove |

High speed |

| Film chuck |

1. The film clamping system has almost no abrasion after long-term use, 2. The HSK installation method becomes the perfect interface for the 3. After combining with HSK, the accuracy of reinstallation after the jaws 4. The medium transmission system can directly spray coolant or compressed |

High-precision grinding or hard turning |

| Rear pull type power chuck | 1. High clamping accuracy. 2. Long guide wedge sleeve. 3. Super long guide support column. 4. Wedge transmission mechanism. 5. The support column with large contact surface has high stability. |

High speed cutting |

| Floating chuck |

1. The centering parts can be replaced, with elastic top and fixed top for |

Shaft workpiece machining |

| Power composite chuck |

1. The 3 power telescopic jaws of the end drive that can transmit limited 2. It has a wide range of use, and different workpiece diameters can be 3. If you are using an end driver with a fixed center, the chuck needs to |

Multi-axis CNC lathe machining |

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!