15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

142 |

Published by VMT at Jul 30 2021

142 |

Published by VMT at Jul 30 2021

In recent years, people's requirements for metal precision machined parts have become higher and higher. While people are pursuing quality, they are also pursuing aesthetics. Therefore, metal precision machined parts surface treatment is essential.

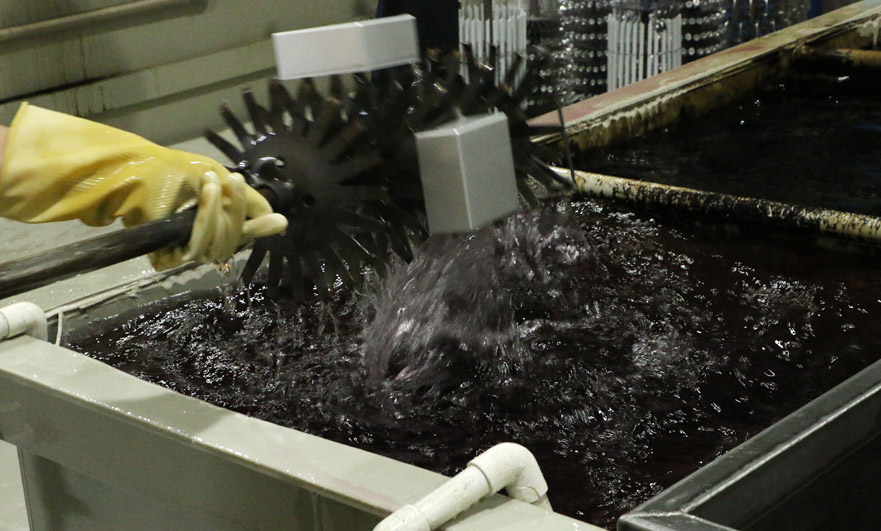

No matter what material it is, it is inseparable from the processing process. It is a variety of surface treatment processes, such as metal precision machined parts shell surface treatment processes including sandblasting, electroplating, PVD, spraying, anodizing and so on.

However, the yield problem has always plagued most people. Today I will talk to you about how to improve the yield of anodizing precision machined parts.

Yield rate refers to the ratio of the number of precision machined parts that finally pass the test to the theoretical production number of input materials on the production line. The number of good products that have gone through all the processes is the final yield.

How to improve the yield of anodized precision machined parts?

1. Cleaning: It needs to be cleaned before anodized, reduce bruises and bad stains after anodized.

2. Sandblasting: sandblasting one by one to avoid not comprehensive, placed one by one after sand blasting, and can not be stacked.

3. Oxidation: Control the time, in order to control the precision machined parts brightness and matt, to ensure the same color.

4. Coloring: When dyeing, swing the hanger at a constant speed to make the dyeing even and control the dyeing time.

5. Finish: When finished, you need to carefully remove the product to avoid scratches by the hanger.

Summarize

The precision machined parts yield is the ratio of online production input to output. We need to pay attention to details and avoid unnecessary costs.VMT helps you select the ideal surface finish.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!