15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

115 |

Published by VMT at Nov 21 2023

115 |

Published by VMT at Nov 21 2023

Precision and Surface Finish Requirements for Aluminum Alloy CNC Machining:

Precision Requirements:

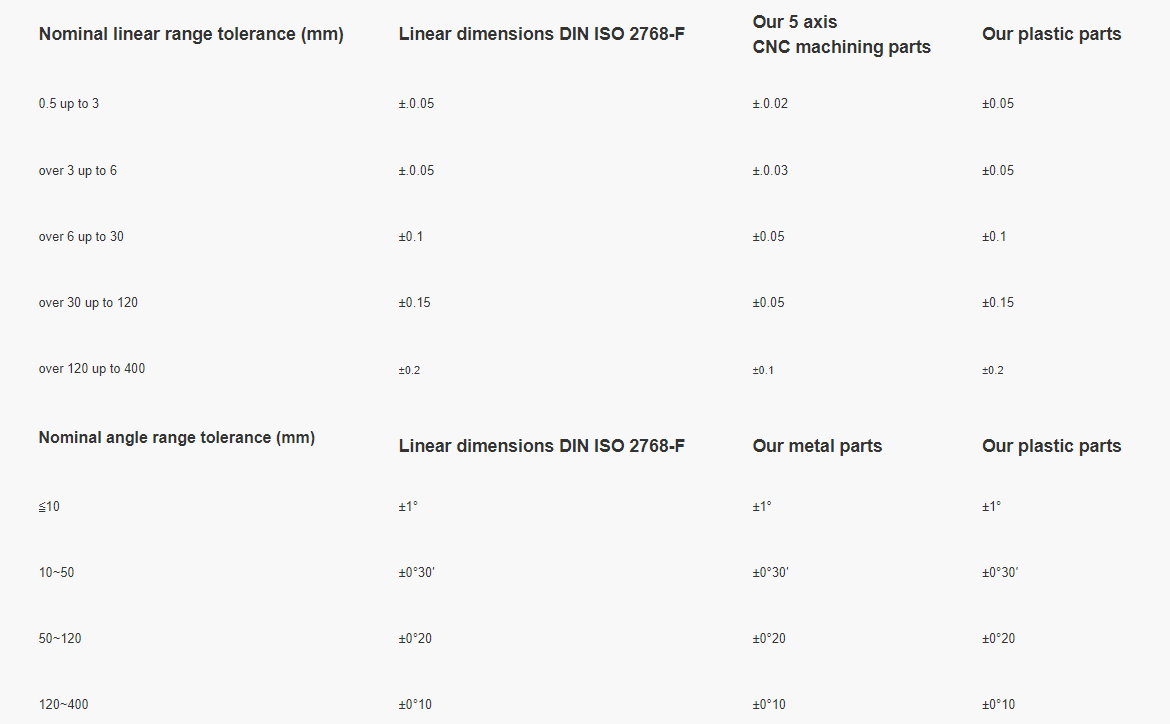

Precision in aluminum alloy CNC machining is often specified in terms of tolerances, which are the allowable deviations from the nominal dimensions. The required precision can vary based on the specific application and the function of the CNC machined part. Commonly, precision is expressed in terms of linear dimensions (e.g., ±0.1 mm) or geometric tolerances (e.g., perpendicularity, parallelism).

Surface Finish Requirements:

Surface finish refers to the quality and smoothness of the machined surface. It is typically measured in terms of Ra, the average roughness value. The surface finish requirement depends on the aesthetic and functional considerations of the application.

Typical Precision Requirements:

Linear Tolerances: ±0.05 mm to ±0.2 mm, depending on the complexity and criticality of dimensions.

Geometric Tolerances: As specified, considering factors like concentricity, symmetry, and positional tolerances.

Typical Surface Finish Requirements:

Ra Values: Commonly in the range of 0.8 μm to 3.2 μm for general applications.

Aesthetic or High-Precision Applications: Ra values below 0.4 μm may be specified for critical surfaces.

Considerations:

Functional Requirements: Precision and surface finish should meet the functional requirements of the part, ensuring proper fit, assembly, and functionality.

Material and Machining Complexity: The type of aluminum alloy and the complexity of the machining process influence precision and surface finish requirements.

Cost and Time Constraints: Tighter tolerances and finer surface finishes may increase production costs and machining time.

Industry Standards: Adherence to industry standards (e.g., ISO standards) can guide precision and surface finish specifications.

It's crucial to collaborate closely with design engineers, machinists, and stakeholders to define appropriate precision and surface finish requirements based on the specific needs of the aluminum alloy CNC machining project. This ensures that the final components meet both functional and aesthetic expectations.

Optimizing Precision and Surface Finish in Aluminum Alloy CNC Machining:

When striving for exceptional results in aluminum alloy CNC machining, additional considerations and optimization strategies play a crucial role in achieving the desired precision and surface finish:

Tool Selection and Condition:

Choosing the right cutting tools is paramount. High-quality, sharp tools contribute to achieving precise dimensions and a smoother surface. Regular tool maintenance and replacement are essential for consistent performance.

Cutting Parameters:

Adjusting cutting parameters, such as cutting speed, feed rate, and depth of cut, influences both precision and surface finish. Optimizing these parameters helps balance the need for efficiency and the achievement of desired results.

Coolant and Lubrication:

Proper coolant and lubrication systems are critical for temperature control during machining. This not only enhances tool life but also contributes to improved surface finish by minimizing heat-induced deformities.

Machine Rigidity and Stability:

Rigidity and stability of the CNC machine are pivotal for precision. A stable machine setup minimizes vibrations, ensuring accuracy in machining operations. This is especially important for achieving tight tolerances.

Post-Machining Processes:

Consideration of post-machining processes, such as deburring and additional surface treatments, can further refine the surface finish. These steps contribute to the removal of sharp edges and enhance the overall aesthetic appeal.

Implementing robust quality assurance measures throughout the machining process is vital. In-process inspections and final quality checks help identify and rectify any deviations from specified tolerances and surface finish requirements.

Understanding the characteristics of the specific aluminum alloy being machined is essential. Some alloys may exhibit different machinability, thermal conductivity, and hardness, influencing the machining strategy for optimal results.

Collaboration and Communication:

Effective communication between design engineers and machinists ensures a clear understanding of precision and surface finish requirements. Collaboration facilitates the exchange of insights, leading to better decision-making throughout the machining process.

By integrating these considerations into the CNC machining workflow, manufacturers can enhance their ability to consistently achieve the desired precision and surface finish in aluminum alloy components. This comprehensive approach aligns machining strategies with the specific characteristics of the material and the expectations set by the project requirements.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!