15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

65 |

Published by VMT at Nov 22 2023

65 |

Published by VMT at Nov 22 2023

Yes, CNC machining manufacturers commonly offer both sample production and small batch manufacturing services to cater to a wide range of customer needs. Here's an overview of these services:

Sample Production:

CNC machining manufacturers often provide sample production services, allowing customers to receive a small quantity of prototypes or test parts before committing to larger-scale production.

Samples are valuable for evaluating the design, fit, and functionality of the machined components. They help identify any potential issues or improvements needed before full-scale manufacturing.

Small Batch Production:

Many CNC machining facilities specialize in small batch production, offering the flexibility to produce limited quantities of parts or components.

Small batch production is beneficial for customers who require a moderate quantity of machined parts without the need for large-scale manufacturing. It is a cost-effective solution for various industries and applications.

Benefits of These Services:

Cost-Effective Prototyping: Sample production allows customers to prototype their designs without the expenses associated with full-scale production runs. It's an efficient way to test and refine concepts.

Flexible Manufacturing: Small batch production offers flexibility in meeting varying production volume requirements. It accommodates orders that fall between prototype quantities and larger production runs.

Reduced Lead Times: CNC machining, with its computerized automation, enables efficient and timely production, leading to shorter lead times for both samples and small batches.

Customization and Adaptability:

CNC machining manufacturers can easily adapt to different design specifications, making it feasible to customize samples and small batches according to specific customer requirements.

This adaptability is particularly advantageous for industries with evolving design needs or those producing specialized components.

Reputable CNC machining manufacturers maintain rigorous quality control processes, ensuring that both samples and small batches meet the required standards. This commitment to quality extends to larger production runs as well.

In summary, CNC machining manufacturers are well-equipped to provide sample production for prototyping and small batch manufacturing services. These offerings empower customers with the flexibility to test designs, validate concepts, and obtain small quantities of high-quality machined parts before scaling up production.

Scalable Solutions for Diverse Needs: CNC Machining Manufacturers at Your Service

In addition to sample production and small batch services, CNC machining manufacturers offer a continuum of solutions to meet the diverse needs of their clientele:

Medium to Large-Scale Production:

Beyond samples and small batches, CNC machining facilities are fully equipped to handle medium to large-scale production runs. This scalability is advantageous for industries with growing demands or projects requiring a higher volume of precision-engineered components.

Multi-Axis Machining Capabilities:

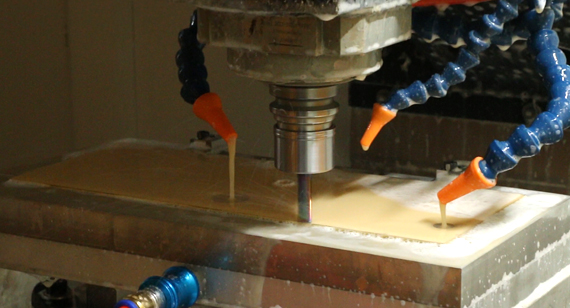

Many CNC machining manufacturers boast advanced multi-axis machining capabilities. This technological edge enhances their capacity to produce intricate parts with complex geometries, ensuring precision and efficiency across various production volumes.

CNC machining supports a wide range of materials, including metals, plastics, and composites. Manufacturers are adept at working with diverse materials to meet the specific requirements of different industries, applications, and end-use scenarios.

Rapid prototyping is a hallmark of CNC machining manufacturers. Leveraging the speed and precision of computer-controlled machining, manufacturers can quickly produce prototypes for evaluation, testing, and validation, facilitating an agile product development process.

Value-Added Services:

Beyond machining, manufacturers often provide value-added services such as surface finishing, coating, and assembly. These services add an extra layer of customization and convenience for clients seeking comprehensive solutions.

Collaborative Partnerships:

CNC machining manufacturers thrive on collaboration with clients. By engaging in open communication, manufacturers can better understand the unique requirements of each project, ensuring that the final products align perfectly with the intended application.

Quality Assurance and Certification:

To uphold industry standards and meet regulatory requirements, CNC machining manufacturers prioritize quality assurance. Many facilities are certified to international standards, underscoring their commitment to delivering precision, reliability, and consistency in every production batch.

In conclusion, CNC machining manufacturers serve as versatile partners capable of adapting to the evolving needs of their clients. Whether it's prototyping, small batches, or large-scale production, these manufacturers leverage cutting-edge technology and expertise to deliver high-quality, precision-engineered components across a spectrum of volumes and complexities.

Find a reliable CNC machining partner

Do you know how to choose the right CNC machining manufacturer for your project? VMT has 15 years of experience in surface treatment experts and engineers to choose the appropriate processing technology and surface treatment for you to improve the surface texture and performance of CNC parts.

We provide custom CNC metal machining services for stainless steel, aluminum, titanium, copper and more. Whether it's prototyping or low-volume production of parts, our team of professional engineers can select the right surface treatment to meet your needs to a high standard. Then, simply upload your CAD files to our email: inquiry@vimetal.com.cn to get a project quote.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!