15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

136 |

Published by VMT at Jul 21 2022

136 |

Published by VMT at Jul 21 2022

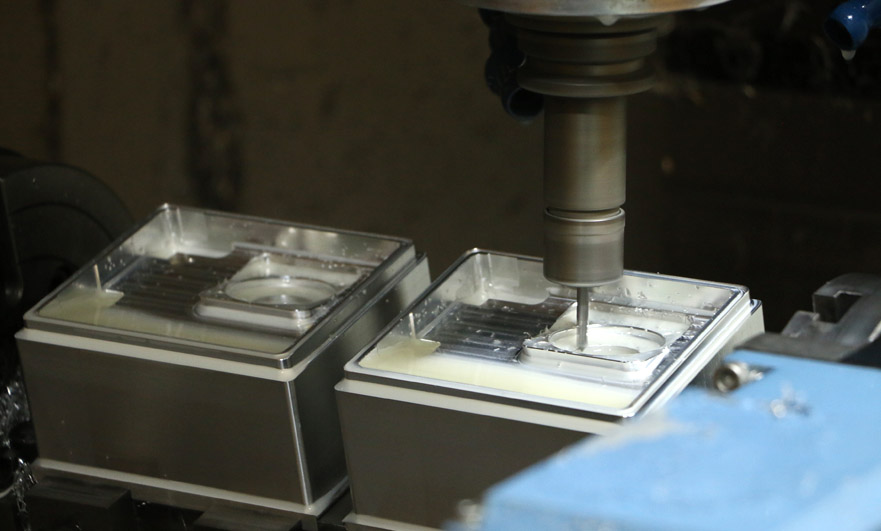

Why is CNC machining manufacturer proofing so expensive? I believe that many friends who do not know CNC machining parts manufacturers will have this question, so today I will talk to you, what is the reason why CNC machining parts proofing is so expensive? Here's my answer to why:

The cost of fees

First of all, we must understand the composition of the cost, CNC machining cost = material cost + processing cost + labor cost + surface treatment cost + tax. Among them, the CNC processing fee is an important factor leading to the disparity in the cost. So the main reason for the high and low processing fees is whether the CNC machining technology is reasonable? For example, it is difficult to process a feature with a CNC machine tool, and the CNC machining time is long, but wire cutting can be easily solved. If you insist on using a CNC machine tool to process it, it will undoubtedly increase the time cost and labor cost, and the cost will naturally increase. Therefore, CNC machining manufacturers do not combine multiple processes or do not make reasonable arrangements for the product process before processing, which will increase a lot of unnecessary costs.

No professional CNC machining manufacturer found

I did not find a professional professional CNC machining manufacturer, because the selected machine is different, the CNC machining cost will be different, such as the price and cost of 3-axis CNC machining, 4-axis CNC machining and 5-axis CNC machining. There is no CNC machining manufacturer who has done similar materials. He needs to buy materials to make a CNC machining part, and the cost of a whole piece of material will definitely be high. There is no cost advantage.

CNC machining method

Each CNC machining manufacturer chooses different CNC machining methods, and the cost is definitely different. Some use simple fixtures for CNC machining in several times, and some use professional fixtures to complete the machining at one time, so the processing time is definitely different, and the cost is also different. Not the same, the proofing price will be high and low.

Small workshop CNC machining manufacturer

A small workshop CNC machining manufacturer has no marginal cost advantage, and the processing cost is definitely high. A large-scale CNC machining factory has a scale effect, so it has more advantages in cost.

The cost of proofing for CNC machining manufacturers is divided into: material cost, fixture cost, tool cost, and processing cost. If there are advantages in these aspects, the cost will be reduced.

When choosing a CNC machining manufacturer, it is very important whether the CNC machining equipment is complete and flexible. If you are still looking for CNC machining manufacturers, you may wish to know about VMT, VMT has been focusing on CNC precision machining parts service for 13 years, our business has spread to 62 countries around the world, covering different fields, such as military, medical, semiconductor, and automotive fields. Provide free service design, project review and DFM analysis. In order to ensure the quality of parts, we passed the ISO9001 quality system and SGS On-site factory audit in 2015. No matter how complicated your part structure is, or if you encounter technical problems with your product, we can provide you with professional services! Save you 15% time cost and communication cost!

The above points hope to help you choose a low-cost CNC machining proofing manufacturer for reference!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!