15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

125 |

Published by VMT at Jul 21 2022

125 |

Published by VMT at Jul 21 2022

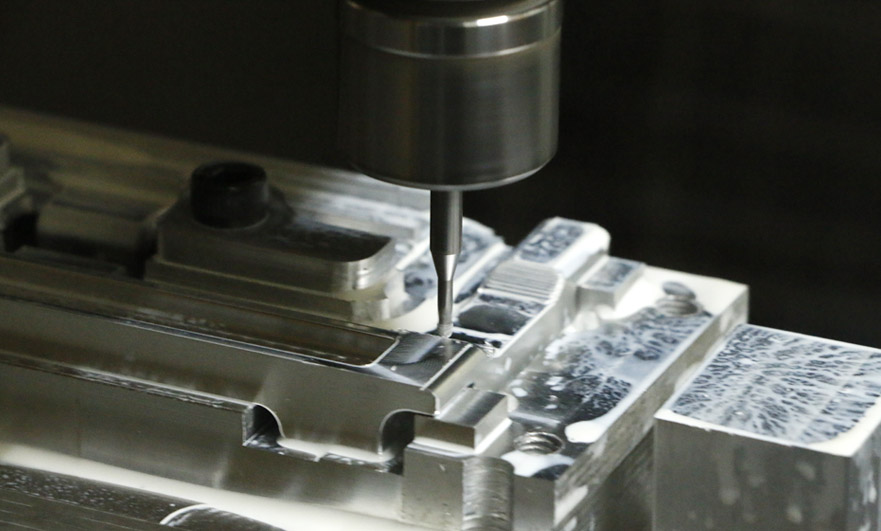

CNC precision machining parts can be cut according to production needs, and then some small parts can be cut by gong or CNC processing, while CNC precision machined parts must be punched, then welded, then sanded and sprayed. After the accessories is made. It should be reminded that small parts also need to be electroplated or sprayed on the surface after grinding. There are many cases of batch processing of CNC precision machined parts. Therefore, the accuracy of CNC machined parts determines the quality of the product. The more precise CNC machined parts are, the higher the accuracy requirements will be. So why does the precision of CNC precision machined parts deteriorate?

1. The machining accuracy of CNC precision machining parts itself is poor. Generally speaking, if the dynamic error between the shafts is not adjusted properly during installation, or because the shaft transmission chain changes due to wear, the accuracy of CNC precision machining parts will be affected. Generally speaking, the accuracy deviation caused by this type of error can be solved by readjusting the compensation amount. If the error is too large or even if an alarm occurs, it is necessary to check the servo motor to observe whether its speed is too high.

2. The overshoot of the machine tool will also affect the accuracy of CNC precision machining parts during operation. It may be because the acceleration and deceleration time is too short, and the change time should be appropriately extended. Of course, it is also very likely because the connection between the screw and the servo motor is loose.

3. Because the roundness caused by the linkage of the two axes is out of tolerance, the machine is not adjusted well to form the axial deformation of the circle, the screw clearance of the axis is not compensated correctly, or the axis positioning is offset, which may affect the accuracy of CNC precision machined parts. influences.

CNC precision machining parts process:

1. The CNC machining process route has great uncertainty. A precision CNC machining part or product can have a variety of processes, and the production process requires a wide variety of machinery and equipment and fixtures.

2. As manufacturers of CNC precision machining parts are mainly scattered, the quality and productivity of products depend to a large extent on the technical level of workers, and the degree of automation is mainly at the unit level, such as CNC machine tools, flexible manufacturing systems, etc.

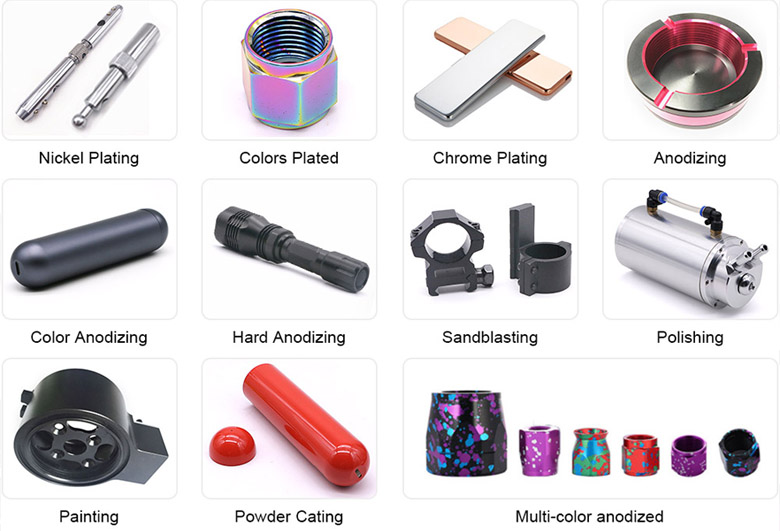

3. CNC precision machining parts generally adopt a combination of self-made and external processing. For example, special processes such as electroplating, sandblasting, oxidation, and silk-screen laser engraving will be entrusted to external manufacturers for processing.

4. There are many CNC precision machining parts required. The workshop site often needs to fill in a large number of material requisitions and will see "one-line" production orders. If there is process management, a large number of process transfer orders need to be filled in.

VMT has been focusing on CNC precision machining parts service for 13 years, our business has spread to 62 countries around the world, covering different fields, such as military, medical, semiconductor, and automotive fields. Provide free service design, project review and DFM analysis. In order to ensure the quality of parts, we passed the ISO9001 quality system and SGS On-site factory audit in 2015.No matter how complicated your part structure is, or if you encounter technical problems with your product, we can provide you with professional services!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!