15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

127 |

Published by VMT at Jul 20 2022

127 |

Published by VMT at Jul 20 2022

CNC machining is because it has multiple advantages. While CNC machining can guarantee higher productivity and fewer errors than traditional CNC machining, quality inspection is still an integral part of the CNC machining process. Quality control and inspection are carried out at various stages of CNC machining. Also, quality assurance is one of the most important aspects and it is different from quality control. Quality assurance refers to the quality inspection process set by organizations and authorized bodies. This also includes related documents. Therefore, we can say that quality assurance is the establishment of processes and documents, whereas quality control is carried out on a regular basis or as required.

Quality control is the most important aspect of every manufacturing industry - whether it's a product, part, process, tool or machine. No matter what industry you are in, product quality is the most important thing. To meet customer expectations, trade standards and industry regulations, VMT uses different measuring instruments and tools to control the quality of each CNC precision machined part.

This article discusses the importance of such quality checks and methods to CNC machining and quality control methods.

Detect

Detection occurs at three levels, as described below:

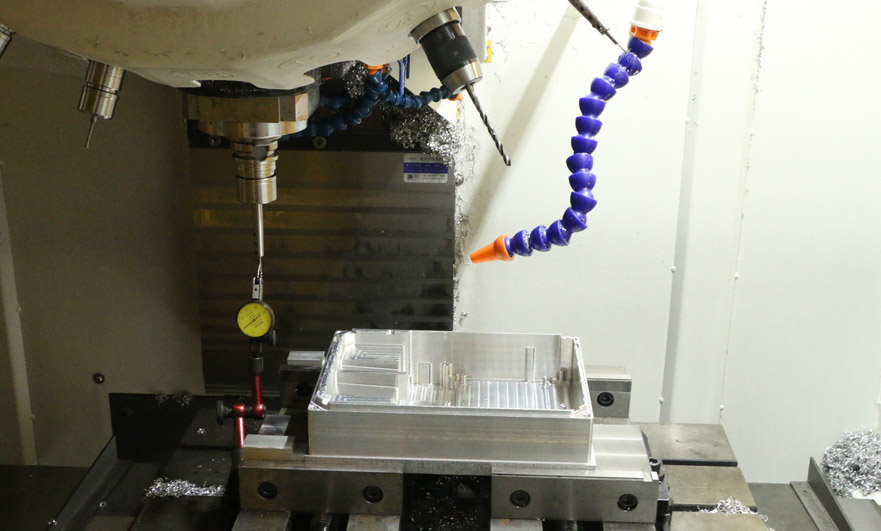

CNC machining machine accuracy test:

In this mode, the alignment and movement accuracy of the machine tool is checked. Check various other parameters such as the orientation of the spindle, support, axis, etc. The spindle should be perpendicular to the table. The angle and curvature of the shaft must be accurate. Check the linear axis.

CNC precision machining parts test:

In this mode, the size and position of CNC precision machined parts are checked. This also includes checking parameters such as positioning, surface finish and shape. Also check for dimensional and geometric tolerances depending on the requirement or application.

Process Monitoring:

This includes reviewing process steps at each stage to avoid process-related errors that could lead to defective products or unnecessary manufacturing delays. There are different stages in the product life cycle, starting from ideation or conceptualization. Then comes design, feasibility study, analysis, pilot production phase, testing, mass production, etc. The quality inspection here involves all levels.

Parameters to be checked during CNC machining quality inspection

The following are some parameters that must be checked during the quality inspection of CNC machine tools:

When CNC precision machining parts, the purpose of rapid prototyping must be achieved. Make sure your machine can make the products and prototypes you need.

Aim for tight tolerances to ensure your machine delivers the precision you need with minimal margin for error.

Check the spindle on CNC machining equipment

Make sure the machine is accurately calibrated, there will be errors over time.

If you do not have well-equipped QC personnel, please seek professional testing service providers.

Document the inspection results and record them for future reference.

Choose an ISO certification level; this provides a certain level of credibility.

If you outsource this function, check the trustworthiness of the CNC machining service manufacturer and maintain open communication with them.

Quality Control

Why is quality control of CNC precision machined parts important?

Quality control is a comprehensive inspection of the product and manufacturing process. In CNC machining, quality control is essential to ensure that manufactured products meet the standards and requirements of businesses, industries and customers. In addition, proper quality control of CNC precision machined parts will avoid the production of defective products, minimize risks, ensure dimensional accuracy and quality, save resources, reduce costs, and improve efficiency. This is good for both the manufacturer and the customer.

Therefore, an effective quality control system should be established starting from the definition and establishment of quality standards for each part. Professional quality control and inspection personnel are also required.

How to carry out quality control?

Customer Communication

Effective customer communication is an essential element in achieving customer satisfaction. It is effective to communicate with customers in a timely manner, no matter in the process of CNC machining and manufacturing or after sending samples. Buyers and customers have clear requirements for product specifications and functions. When we receive an inquiry from a customer, we will contact them as soon as possible and give a free quote as soon as possible. If something goes wrong, we will adjust the solution immediately. If you have special requirements, please let us know in advance.

Understand the design of CNC precision machined parts

When the customer sends the CAD drawing of the final product, the engineer needs to analyze the design in detail, understand the customer's product specifications and requirements, and check every detail before production. We will CNC machine your part using the most cost-effective solution, controlling factors throughout the CNC process to ensure requirements are met.

Product

Monitoring and measurement procedures for all CNC precision machined parts are defined in drawings and specifications, production routers, purchasing documents, and inspection and testing procedures.

Validation of purchased products

All purchased products are visually inspected by receiving inspectors. Selected products are also subject to more detailed technical quality control (QC) checks.

Process inspection

In-process inspections take the form of first article inspections and operator inspections to ensure our quality and deliver completed orders to customers on time.

CNC precision machined parts undergo final QC inspection. First, the inspector confirms that all specified and in-process inspections have been completed. They then perform the remaining inspections and tests to complete the product compliance demonstration. The results of all inspections and tests are recorded and only products that pass the final inspection process are packaged and shipped.

The operator will handle the final part after CNC machining. There are various advanced measurement tools available for many inspection measurements such as size, hardness, color, tolerance, etc.

Machining inspection

All our CNC precision machined parts are quality controlled to ensure high precision and accuracy. We pay attention to detail and customer satisfaction, so an independent inspection department can conduct consistent inspection of each part to ensure products are of high quality and precision.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!