15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

763 |

Published by VMT at Jun 10 2022

763 |

Published by VMT at Jun 10 2022

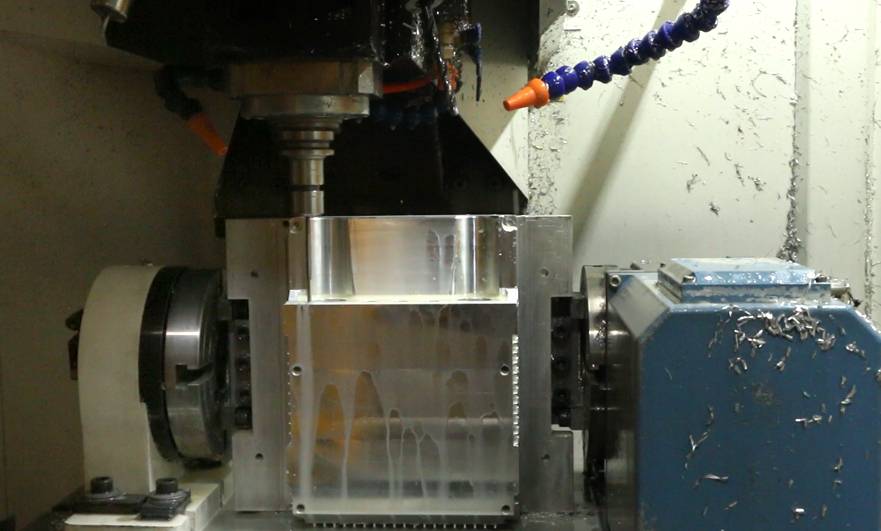

In the actual CNC machining production process, there are five main factors that affect the CNC machining accuracy.

1. The machine tool is heated up

In the process of operation, the CNC machine tool itself will generate a certain amount of heat, such as motor operation, component friction and other factors, which will cause the temperature of the machine tool to continue to rise, resulting in adverse effects on components and structural systems due to thermal effects, such as tool shift in the machine tool. , CNC machining parts wear, thermal expansion of components, line burning and other phenomena, resulting in reduced CNC machining accuracy of parts. In addition, the installation of machine tools is mostly in unventilated places, and external environmental conditions such as limited heat dissipation conditions will also cause the temperature to rise. This will increase the burden of machine tool operation, reduce the accuracy of CNC machining parts, and in severe cases may cause mechanical failures, which directly affect the efficiency and quality of CNC machining.

2. The error and wear of the tool itself

The tool in the machine tool is also one of the CNC machining parts. In its own production and machining process, there are geometric errors that affect the accuracy due to the limitation of CNC machining conditions. In the process of tool installation, human operation will also affect the machining accuracy. In the process of use, due to the long-term contact between the tool and the CNC machined parts, the deformation caused by friction and high temperature and other factors will also cause the tool to wear to varying degrees. Of course, when the wear accumulates to a certain extent, it will also have a significant impact on the CNC machining accuracy.

3. CNC machining position error

CNC machining parts all have basic error requirements such as surface, shape, radian, relative relationship, etc. CNC machining must complete the design requirements of the parts and meet the machining performance and quality requirements. In the process of CNC machining, due to the influence of various factors such as transmission parts, rotating shafts, and frictional forces of parts, the accuracy of the appearance, size, and relative relationship of CNC machined parts is deviated, which reduces the accuracy of parts machining. For example, in the process of CNC machining, the swing angle of the CNC machining axis will be wrong, which will cause the shape of the CNC machined parts to be deformed, the accuracy will be reduced, and even cause the CNC machined parts to be scrapped in batches, which will bring great economic losses to the enterprise.

4. Error of CNC machining system

The machine tool machining system of CNC machine tools is the part that directly implements parts machining. It is a whole that is composed of multiple subsystems and sub-components in a certain way and operates together. The operation of each component will affect the CNC machining of the entire machining system. Accuracy has an impact. Therefore, the system error is constantly generated by multiple components in the process of installation and operation, and the error of the machining system can only be minimized by means of technological progress and improvement of construction progress.

5. Deformation error

During the long-term use of CNC machining, CNC machine tools will be affected by external forces, such as clamping force, gravity, friction, etc., which will cause deformation, loosening, elastic deformation, displacement and other deformation phenomena of the CNC machining system of the machine tool, resulting in machine tool failure. Production accuracy and production efficiency decline. Under the influence of external force, the machine tool will not only reduce the precision of production CNC machining, but also cause damage to the machine tool in severe cases, affecting the service life. Therefore, it is necessary to pay attention to the research on the influence factors of external force on CNC machine tools to reduce the influence on the machine tools.

If you want to know more about CNC machining knowledge and problems, please contact us, we can help you solve it.

VMT is a professional CNC machining manufacturer with 13 years of experience in precision custom CNC machining production. With professional CNC machining and production equipment, and through a complete quality control system, CNC machining manufacturers provide one-stop services such as CNC machining, sandblasting, oxidation, silk screen printing, and laser engraving.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!