15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

264 |

Published by VMT at Jul 25 2022

264 |

Published by VMT at Jul 25 2022

What are the reasons for the poor accuracy of CNC machining parts? OEM CNC machining parts manufacturers answer some of the questions that often arise in actual CNC machining.

1. The dimensional changes caused by the system are not stable.

Causes of failure: unreasonable parameter setting of CNC machining system; unstable working voltage; system is disturbed by outside, causing the system to lose synchronization; increased capacitance, but the impedance between the system and the driver does not match, resulting in loss of useful signals; The signal transmission between the two is abnormal; the CNC machining system is damaged or inside.

Solution: The CNC machining speed and acceleration time are too large, whether the spindle speed and cutting speed are reasonable, and whether the operator's parameter modification causes the system performance to change; Interference absorption capacitor; select the appropriate capacitor type; check whether the signal connection between the system and the driver is shielded, whether the connection is reliable, and whether the system pulse signal is lost or increased.

2. CNC machining parts produce taper dimensions.

Causes of failure: The level of the CNC machine tool is not adjusted well, one is high and the other is low, and the placement is unstable; when CNC turning the long axis, the feeding is relatively hard, and the tool eats the knife deeper, resulting in the phenomenon of cutting knife; the tailstock thimble is not concentric with the spindle.

Solution: Use a spirit level to adjust the level of the machine, lay a solid foundation, and fix the machine to improve its toughness; choose a reasonable CNC machining process and appropriate cutting feed to avoid the tool being forced to make the tool; adjust the tailstock.

3. The drive phase light is normal, and the size of CNC machining parts is large or small.

Cause of failure: long-term high-speed operation of machine tool frame leads to wear of lead screw and bearing; repeated positioning accuracy of tool post is deviated during long-term use; trolley can accurately return to the starting point of CNC machining every time, but the size of CNC machining parts will still change. This phenomenon is generally caused by the spindle. The high-speed rotation of the spindle causes serious bearing wear, resulting in changes in CNC machining dimensions.

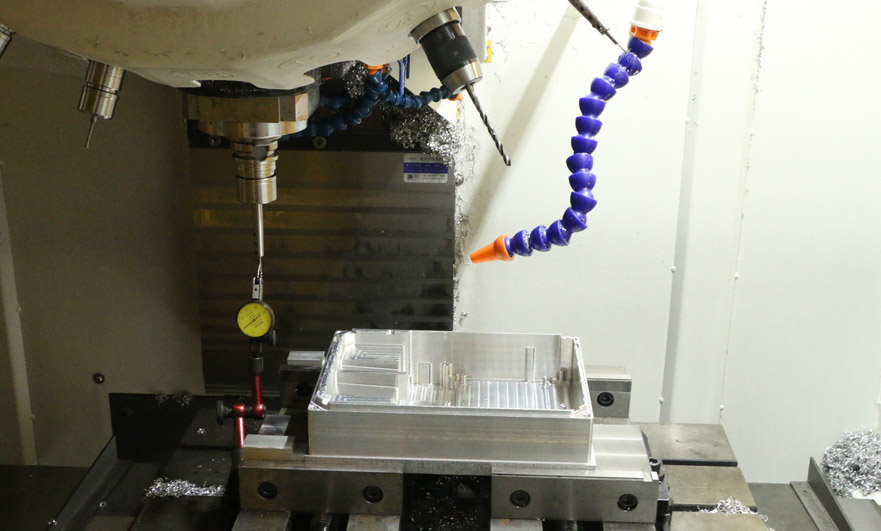

Solution: use a dial indicator against the bottom of the tool holder, edit the canned cycle program through the system, check the repeat positioning accuracy of the trolley, adjust the lead screw gap, and replace the bearing; use a dial indicator to check the repeat positioning accuracy of the tool holder. Adjust the CNC machining machine or replace the tool holder; use a dial indicator to check whether the CNC machining part is accurately returned to the starting point of the program. If possible, repair the spindle and replace the bearings.

4. The size of CNC machined parts differs from the actual size by a few millimeters, or there is a large change in one of the axes.

Causes of failure: The fast positioning speed is too fast, and the driver and motor have no response; after long-term friction loss, the mechanical lead screw and the bearing are stuck too tightly; after the tool change, the tool holder is too loose, and the locking is not tight; the editing program is wrong, the head and tail are not Reaction or no cancellation tool completed; electronic gear ratio or step angle of the system is set incorrectly.

Solution: If the fast positioning speed is too fast, adjust the speed appropriately. Cutting acceleration and deceleration and time will make the drive and motor work normally at the rated operating frequency. When the CNC machining machine is worn, the trolley and screw crane bearings will be too tight. The repair must be re-adjusted. If the tool holder is too loose after the tool change, check whether the reversing time of the tool holder is satisfied, check whether the worm gear in the tool holder is worn, whether the gap is too large, whether the installation is too loose, etc. If it is caused by the program, the program must be modified, according to the requirements of CNC machining parts drawings, select a reasonable CNC machining process, and write the correct program according to the instructions in the manual.

The above are the 4 reasons and solutions for the poor precision of CNC machined parts. The influence of various aspects will lead to differences in the precision of the final CNC machined parts. Therefore, we must start with the machining accuracy of each aspect to produce the best results. CNC machined parts. If you have any questions, please contact us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!