15 years one-stop China custom CNC machining parts factory

539 |

Published by VMT at Sep 13 2025 | Reading Time:About 5 minutes

539 |

Published by VMT at Sep 13 2025 | Reading Time:About 5 minutes

Choosing the right aluminum alloy can be overwhelming when balancing performance, cost, and processing needs. Many manufacturers struggle with materials that crack, corrode, or limit design flexibility. ADC12 aluminum alloy solves these challenges with excellent castability, strength, and corrosion resistance, making it a go-to choice for die casting projects.

ADC12 aluminum alloy is a die-casting material known for excellent machinability, high corrosion resistance, dimensional stability, and good strength. It is widely used in automotive, electronics, and industrial applications where lightweight, durable, and cost-effective parts are required.

Let’s explore ADC12 aluminum alloy in detail—its characteristics, benefits, and where it outperforms other aluminum alloys in CNC machining and die-casting applications.

ADC12 aluminum alloy is a high-quality die-casting material widely used in automotive, consumer electronics, and industrial equipment. It offers an excellent balance of strength, corrosion resistance, and dimensional stability, making it one of the most common aluminum alloys for die casting and CNC machining parts.

The term DC12 aluminum is often confused with ADC12. In most cases, “DC12” is simply a shorthand or mislabeling of ADC12 aluminum alloy. Internationally, ADC12 corresponds to several equivalent grades, such as A383 (U.S. standard) and Al-Si9Cu3 (European standard). These equivalents share similar composition and properties, making them interchangeable in die casting applications.

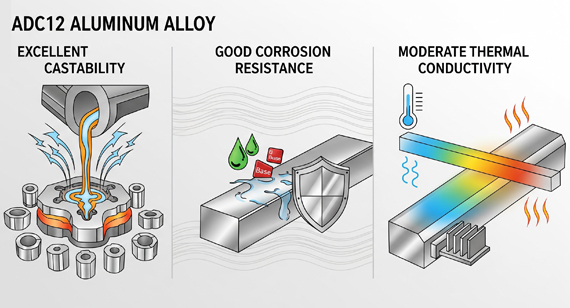

Manufacturers choose ADC12 aluminum alloy because it combines excellent castability, corrosion resistance, and mechanical strength at a reasonable cost. Its ability to flow into thin-walled molds makes it ideal for complex die-cast CNC machining parts. Compared with other alloys, ADC12 offers a balance of performance and affordability, making it a preferred option for high-pressure die casting.

The performance of ADC12 aluminum alloy comes from its carefully balanced chemical composition. Each element—whether copper, silicon, or magnesium—plays a role in defining properties such as strength, corrosion resistance, and castability. Understanding these characteristics helps engineers and designers select ADC12 for reliable die-cast CNC machining parts and cost-efficient production.

ADC12 Aluminum Alloy: Composition

The strength and versatility of ADC12 aluminum alloy are defined by its chemical makeup. It is primarily aluminum but contains copper, silicon, magnesium, and trace elements like zinc, iron, and nickel. Each element contributes unique benefits that improve casting performance and mechanical properties.

Copper

Copper increases strength and hardness in ADC12 aluminum casting. However, too much copper can reduce corrosion resistance.

Zinc

Zinc enhances strength but may lower corrosion resistance if added in excess. Its controlled presence ensures ADC12 maintains durability without sacrificing stability.

Tin

Tin is typically present in very small amounts. It improves machinability but has minimal effect on mechanical strength.

Iron

Iron improves wear resistance and reduces shrinkage during die casting. Excessive iron, however, can cause brittleness.

Magnesium

Magnesium improves strength and corrosion resistance. It also enhances hardness, making ADC12 suitable for high-strength parts.

Manganese

Manganese helps reduce the negative effects of iron and improves overall strength. It also enhances corrosion resistance in humid environments.

Nickel

Nickel increases toughness and resistance to high-temperature deformation. It is especially useful for automotive and machinery applications.

Silicon

Silicon is the most important alloying element in ADC12. It enhances castability, fluidity, and wear resistance while lowering shrinkage defects.

Aluminum

As the base element, aluminum ensures lightweight properties, good corrosion resistance, and excellent thermal conductivity. It provides the foundation for the alloy’s balance of performance and cost.

ADC12 Aluminum Alloy: Composition Table

| Element |

Typical Content (%) |

Role in ADC12 Aluminum Alloy |

| Aluminum (Al) |

Balance (~80–85%) | Provides lightweight base, corrosion resistance, and thermal conductivity. |

| Silicon (Si) |

9.6–12% | Improves castability, reduces shrinkage, enhances wear resistance, lowers machining costs. |

| Copper (Cu) |

1.5–3.5% | Increases strength and hardness, but too much lowers corrosion resistance. |

| Magnesium (Mg) |

≤0.3% | Improves strength, hardness, and corrosion resistance. |

| Zinc (Zn) |

≤1.0% | Adds strength but excessive levels reduce corrosion resistance. |

| Iron (Fe) |

≤1.3% | Improves wear resistance and reduces shrinkage; excess can cause brittleness. |

| Manganese (Mn) |

≤0.5% | Balances iron effects, enhances corrosion resistance, adds strength. |

| Nickel (Ni) |

≤0.5% | Improves toughness and resistance to high-temperature deformation. |

| Tin (Sn) |

≤0.3% | Improves machinability, minimal effect on strength. |

Physical Properties of ADC12 Aluminum Alloy

The physical properties of ADC12 aluminum alloy determine how it performs during die casting, machining, and end use. Key factors such as density, conductivity, and corrosion resistance explain why ADC12 is widely chosen for lightweight yet durable CNC machined parts.

Density

ADC12 has a density of about 2.75 g/cm³, making it significantly lighter than steel while maintaining good strength. This lightweight feature reduces fuel consumption in automotive parts and simplifies handling in manufacturing.

Melting Point

The melting range of ADC12 is around 570–590°C. Its relatively low melting point allows easy die casting and reduces energy consumption during production.

Crack Resistance

ADC12 exhibits good crack resistance thanks to its balanced silicon and magnesium content. This prevents defects during cooling and improves part reliability.

Thermal Conductivity

The alloy has high thermal conductivity (around 96 W/m·K), making it suitable for electronic housings, heat sinks, and automotive engine components.

Electrical Conductivity

While not as conductive as pure aluminum, ADC12 offers moderate electrical conductivity. This is enough for electronic housings where conductivity is required but strength is equally important.

Coefficient of Thermal Expansion

ADC12 has a coefficient of thermal expansion of approximately 22.2 × 10⁻⁶/K. This means it expands with heat but maintains dimensional stability in most operating environments.

Corrosion Resistance

ADC12 shows excellent corrosion resistance due to its aluminum base and protective oxide layer. It performs well in humid environments and resists rusting better than many other metals.

Physical Properties of ADC12 Aluminum Alloy Table

| Property |

Typical Value |

Description / Importance |

| Density |

~2.75 g/cm³ | Lightweight compared to steel, ideal for reducing weight in automotive and machinery parts. |

| Melting Point |

570–590 °C | Low melting range enables efficient die casting and energy savings. |

| Crack Resistance |

Good | Reduces defects during cooling, ensures dimensional stability in thin-walled castings. |

| Thermal Conductivity |

~96 W/m·K | Excellent for heat dissipation in electronics and engine components. |

| Electrical Conductivity |

Moderate (~23% IACS) | Adequate for housings and components needing balanced strength and conductivity. |

| Coefficient of Thermal Expansion |

22.2 × 10⁻⁶/K | Stable expansion with temperature changes, prevents warping in most environments. |

| Corrosion Resistance |

Excellent | Natural oxide layer protects against rust and degradation in humid or outdoor conditions. |

Mechanical Properties of ADC12 Aluminum Alloy

The mechanical properties of ADC12 aluminum alloy determine its strength, durability, and suitability for CNC machining and die casting. These values guide engineers in choosing ADC12 for applications that demand reliability and performance under stress.

| Property |

Typical Value |

Description / Importance |

| Hardness (Brinell) |

~80–100 HB | Provides good wear resistance and durability in automotive and industrial parts. |

| Yield Strength |

~160–170 MPa | The stress level at which ADC12 begins to deform permanently. |

| Tensile Strength |

~310 MPa | Indicates the maximum load ADC12 can withstand before breaking. |

| Modulus of Elasticity |

~71 GPa | Measures stiffness, ensuring dimensional stability under load. |

| Elongation at Break |

~1–3% | Low elongation means less ductility, so parts are strong but not highly flexible. |

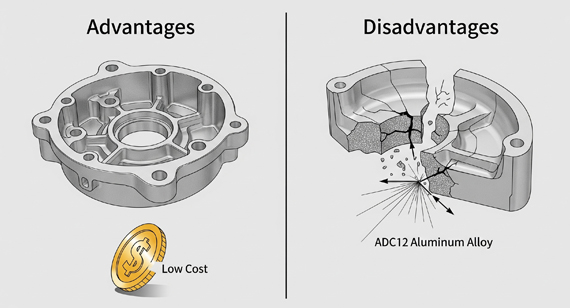

Like all materials, ADC12 aluminum alloy has both strengths and limitations. Its advantages make it a top choice for die casting and CNC machining, while its disadvantages must be considered to avoid costly design or production issues.

Advantages of ADC12 Aluminum Alloy

ADC12 is widely used because it balances performance, castability, and cost. Below are the main benefits:

Good Machinability

Tip: Good machinability means lower costs, but confirm tool coatings are optimized for aluminum to maximize efficiency.*

Excellent Castability

Tip: Excellent castability lowers scrap rates, reducing project costs.*

Excellent Corrosion Resistance

Tip: For extreme environments, consider additional coatings to boost resistance further.*

Excellent Dimensional Stability

Tip: Dimensional stability reduces rework, saving both time and cost.*

Good Flowability

Tip: Good flowability allows more design flexibility, reducing assembly needs.*

Excellent Thermal Conductivity

Tip: High thermal conductivity can eliminate the need for extra cooling systems, lowering design costs.*

Disadvantages of ADC12 Aluminum Alloy

Despite its advantages, ADC12 has limitations:

Tip: Before choosing ADC12 aluminum alloy casting, evaluate mechanical requirements. If higher ductility or heat-treatable properties are essential, alternatives like 6061 or 7075 may reduce long-term costs.

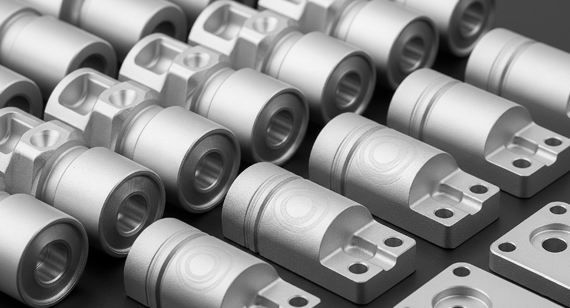

ADC12 aluminum alloy is one of the most popular choices for high-pressure die casting because it combines excellent fluidity, low shrinkage, and reliable mechanical strength. It performs well in thin-walled and complex-shaped parts, making it ideal for automotive housings, electronic enclosures, and machinery components. Compared with other alloys, ADC12 balances performance, cost, and availability, which is why many CNC machining factories recommend it.

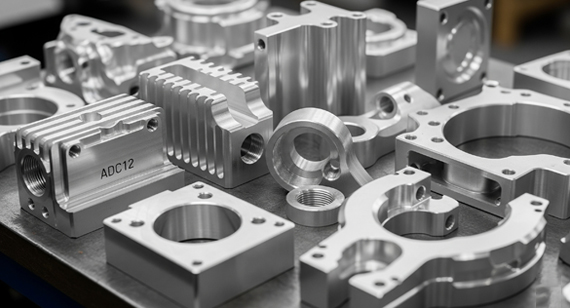

The versatility of ADC12 aluminum alloy makes it suitable for a wide range of industries. Its excellent castability, dimensional stability, and corrosion resistance allow manufacturers to produce reliable, lightweight, and cost-effective die-cast CNC machining parts across multiple sectors.

ADC12 is widely used in automotive parts such as engine housings, transmission cases, and structural components. Its lightweight properties help reduce vehicle weight, improving fuel efficiency without compromising strength.

Machinery

In machinery, ADC12 aluminum alloy casting is used for housings, brackets, and structural supports. Its good strength and wear resistance make it reliable under continuous operation.

Consumer Electronics

ADC12 is popular for electronic device housings, heat sinks, and connectors because of its thermal conductivity and ability to form thin, complex shapes.

Home Appliances

From washing machine parts to microwave housings, ADC12 aluminum casting ensures strength and stability while keeping products lightweight and durable.

Industrial Equipment

In heavy-duty industrial tools and equipment, ADC12 aluminum alloy CNC machining parts provide strength, corrosion resistance, and heat dissipation for reliable long-term use.

ADC12 Aluminum: Applications and Uses

| Industry |

Typical Applications |

Key Benefits of Using ADC12 |

| Automotive |

Engine housings, transmission cases, brackets, structural parts | Lightweight, strong, reduces fuel consumption, excellent dimensional stability |

| Machinery |

Gear housings, brackets, supports, covers | Good wear resistance, strength under continuous operation, cost-effective production |

| Consumer Electronics |

Device housings, heat sinks, connectors | High thermal conductivity, thin-walled casting ability, corrosion resistance |

| Home Appliances |

Washing machine parts, microwave housings, compressor covers | Lightweight, stable, reduces vibration and noise |

| Industrial Equipment |

Power tool casings, pump housings, heavy-duty enclosures | Strength, corrosion resistance, excellent heat dissipation for long-term durability |

Comparing ADC12 aluminum alloy with other aluminum grades helps manufacturers select the right material for die-cast CNC machining parts. Differences in composition, mechanical properties, and thermal behavior determine suitability for automotive, electronics, and industrial applications. This comparison highlights where ADC12 excels and where other alloys may be preferred.

ADC12 Aluminum vs. 6061 Aluminum

While ADC12 is a die-casting alloy, 6061 aluminum is a heat-treatable wrought alloy. Both are widely used in CNC machining, but they differ in composition, strength, corrosion resistance, and suitable applications. Understanding these differences ensures the best choice for cost, performance, and manufacturability.

Elemental Composition Comparison

| Element |

ADC12 |

6061 |

Notes |

| Aluminum (Al) |

~80–85% | ~97.9% | 6061 is mostly pure aluminum, ADC12 contains more alloying elements. |

| Silicon (Si) |

9.6–12% | 0.4–0.8% | High Si in ADC12 improves castability; 6061 is lower for wrought strength. |

| Copper (Cu) |

1.5–3.5% | 0.15–0.4% | ADC12 has more copper, increasing hardness but reducing corrosion resistance slightly. |

| Magnesium (Mg) |

≤0.3% | 0.8–1.2% | Higher Mg in 6061 allows heat treatment strengthening. |

| Others (Fe, Mn, Zn, Ni, Sn) |

≤2% combined | Trace | ADC12 has more alloying diversity for castability and flow; 6061 focuses on weldability. |

Mechanical Property Comparison

| Property |

ADC12 |

6061 |

Notes |

| Tensile Strength |

~310 MPa | 290–310 MPa | Similar strength, but ADC12 is brittle; 6061 is more ductile. |

| Yield Strength |

~160–170 MPa | 240 MPa | 6061 can sustain higher stress before permanent deformation. |

| Elongation |

1–3% | 10–12% | 6061 is much more ductile, ADC12 is more brittle. |

| Hardness (HB) |

80–100 | 95–105 | Comparable, but ADC12 hardness comes from Si-Cu alloying. |

Physicochemical Property Comparison

| Property |

ADC12 |

6061 |

Notes |

| Density |

2.75 g/cm³ | 2.70 g/cm³ | ADC12 slightly heavier due to alloying. |

| Melting Point |

570–590°C | 582–652°C | ADC12 easier to die-cast; 6061 requires higher temperature for casting/welding. |

| Corrosion Resistance |

Excellent | Excellent | 6061 slightly better in marine environments. |

| Thermal Conductivity |

96 W/m·K | 167 W/m·K | 6061 conducts heat better, ADC12 still sufficient for most applications. |

Application Comparison

| Application |

ADC12 |

6061 |

| Die-cast CNC parts |

Excellent | Not suitable for high-pressure die casting |

| Automotive |

Engine housings, brackets | Structural frames, chassis |

| Electronics |

Housings, heat sinks | Structural support, casings |

| Industrial |

Machinery covers, fittings | High-strength components |

ADC12 vs. A380 Aluminum

A380 aluminum is another widely used die-casting alloy. Comparing it with ADC12 highlights differences in composition, strength, and suitability for CNC machining and die-cast parts. Both alloys are popular in automotive and electronics, but ADC12 offers slightly better corrosion resistance, while A380 is easier to cast for very complex shapes.

Elemental Composition Comparison

| Element |

ADC12 |

A380 |

Notes |

| Aluminum (Al) |

~80–85% | ~78–80% | A380 has slightly less aluminum, more alloying elements. |

| Silicon (Si) |

9.6–12% | 7–9% | ADC12 has higher silicon, improving corrosion resistance and wear properties. |

| Copper (Cu) |

1.5–3.5% | 3–4.5% | A380 is stronger due to higher Cu content but less corrosion-resistant. |

| Magnesium (Mg) |

≤0.3% | ≤0.3% | Similar levels, minor impact on properties. |

| Zinc (Zn) |

≤1% | ≤1% | Comparable. |

| Iron (Fe) |

≤1.3% | ≤1.3% | Similar, contributes to wear resistance. |

| Others (Mn, Ni, Sn) |

≤1% combined | ≤1% combined | Trace elements similar, minor effect. |

Mechanical Property Comparison

| Property |

ADC12 |

A380 |

Notes |

| Tensile Strength |

~310 MPa | ~290 MPa | ADC12 slightly stronger overall. |

| Yield Strength |

~160–170 MPa | ~130 MPa | ADC12 better for load-bearing thin-walled parts. |

| Elongation |

1–3% | 1–2% | Both alloys are brittle; ADC12 slightly more ductile. |

| Hardness (HB) |

80–100 | 75–95 | ADC12 harder due to higher silicon content. |

Physicochemical Property Comparison

| Property |

ADC12 |

A380 |

Notes |

| Density |

2.75 g/cm³ | 2.68–2.72 g/cm³ | A380 is slightly lighter. |

| Melting Point |

570–590°C | 560–580°C | Both suitable for die casting; A380 slightly lower for easier mold filling. |

| Corrosion Resistance |

Excellent | Good | ADC12 resists corrosion better, ideal for outdoor parts. |

| Thermal Conductivity |

96 W/m·K | 90 W/m·K | ADC12 conducts heat slightly better. |

Application Comparison

| Application | ADC12 | A380 |

| Automotive | Engine covers, brackets | Gear housings, wheels, structural parts |

| Electronics | Housings, heat sinks | Electrical enclosures |

| Industrial | Machinery fittings, covers | Small industrial housings |

| Die Casting Complexity | Moderate to high | Excellent for very complex shapes |

ADC12 Aluminum vs. 7075 Aluminum

7075 aluminum is a high-strength, heat-treatable alloy commonly used in aerospace and high-stress applications. Comparing it with ADC12 highlights differences in strength, ductility, corrosion resistance, and suitability for die-cast CNC machining parts. While ADC12 excels in castability and corrosion resistance, 7075 provides superior mechanical strength.

Elemental Composition Comparison

| Element |

ADC12 |

7075 |

Notes |

| Aluminum (Al) |

~80–85% | 87–91% | 7075 is mostly aluminum with carefully balanced alloying for high strength. |

| Zinc (Zn) |

≤1% | 5.1–6.1% | 7075’s high Zn content provides exceptional strength. |

| Copper (Cu) |

1.5–3.5% | 1.2–2% | Both alloys contain copper, but 7075 relies on it for heat-treatable strength. |

| Magnesium (Mg) |

≤0.3% | 2.1–2.9% | Higher Mg in 7075 improves strength and heat-treatable properties. |

| Silicon (Si) |

9.6–12% | ≤0.4% | ADC12’s high Si improves castability; 7075 is low Si for wrought strength. |

| Others (Fe, Mn, Ni, Sn) |

≤2% combined | Trace | Minor effect on mechanical properties. |

Mechanical Property Comparison

| Property |

ADC12 |

7075 |

Notes |

| Tensile Strength |

~310 MPa | 505–572 MPa | 7075 is much stronger, suitable for high-stress components. |

| Yield Strength |

~160–170 MPa | 435–505 MPa | ADC12 is weaker; 7075 can handle heavier loads. |

| Elongation |

1–3% | 5–11% | 7075 is more ductile, while ADC12 is brittle. |

| Hardness (HB) |

80–100 | 150–180 | 7075 is significantly harder, ideal for high-wear applications. |

Physicochemical Property Comparison

| Property |

ADC12 |

7075 |

Notes |

| Density |

2.75 g/cm³ | 2.81 g/cm³ | 7075 slightly heavier but still lightweight. |

| Melting Point |

570–590°C | 477–635°C | 7075 requires heat treatment, ADC12 is suited for die casting. |

| Corrosion Resistance |

Excellent | Good | ADC12 resists corrosion better; 7075 may require coatings. |

| Thermal Conductivity |

96 W/m·K | 130 W/m·K | 7075 conducts heat better, useful in high-stress environments. |

Application Comparison

| Application |

ADC12 |

7075 |

| Die-Cast CNC Parts |

Excellent | Not suitable for high-pressure die casting |

| Automotive |

Engine covers, brackets | Structural frames, aerospace components |

| Electronics |

Housings, heat sinks | Load-bearing high-strength components |

| Industrial |

Machinery fittings, covers | Aerospace, defense, and high-stress tooling |

ADC12 vs. Cast Aluminum

| Property |

ADC12 |

Generic Cast Aluminum |

Notes |

| Composition |

Al-Si-Cu-Mg | Al-Si (variable) | ADC12 has controlled composition for die casting. |

| Tensile Strength |

~310 MPa | 200–300 MPa | ADC12 generally stronger. |

| Elongation |

1–3% | 1–4% | Similar, ADC12 slightly more ductile. |

| Corrosion Resistance |

Excellent | Moderate | ADC12 better in humid environments. |

| Application |

Die-cast CNC parts, automotive | General castings | ADC12 is preferred for precision parts. |

ADC12 Aluminum Alloy vs. Zinc Alloy

| Property |

ADC12 |

Zinc Alloy (e.g., Zamak 3) |

Notes |

| Density |

2.75 g/cm³ | 6.7–7.1 g/cm³ | ADC12 is much lighter, reducing part weight. |

| Tensile Strength |

~310 MPa | 210 MPa | ADC12 stronger and stiffer. |

| Corrosion Resistance |

Excellent | Good | ADC12 better for outdoor applications. |

| Die-Castability |

Excellent | Excellent | Both suitable, zinc easier for very thin parts. |

| Applications | Automotive, electronics | Small housings, fittings | ADC12 preferred for structural parts; zinc for small detailed components. |

ADC12 vs. 2024 Aluminum

| Property |

ADC12 |

2024 |

Notes |

| Composition |

Al-Si-Cu-Mg | Al-Cu-Mg | 2024 lacks high silicon; better for wrought applications. |

| Tensile Strength |

~310 MPa | 470 MPa | 2024 much stronger, heat-treatable. |

| Elongation |

1–3% | 10–20% | 2024 is more ductile. |

| Corrosion Resistance |

Excellent | Moderate | ADC12 superior in corrosion-prone environments. |

| Applications |

Die-cast parts | Aerospace, structural parts | ADC12 suited for castings; 2024 for high-strength sheets and machined parts. |

ADC12 vs. LM6 Alloy

| Property |

ADC12 |

LM6 (Al-Si) |

Notes |

| Silicon |

9.6–12% | 10–13% | Both high-silicon, good for casting. |

| Copper |

1.5–3.5% | 0.5% | ADC12 stronger due to higher Cu. |

| Tensile Strength |

~310 MPa | 250–280 MPa | ADC12 stronger, suitable for load-bearing parts. |

| Corrosion Resistance |

Excellent | Good | ADC12 better for outdoor exposure. |

| Applications |

Die-cast CNC parts, automotive | General die casting | LM6 often used for engine blocks; ADC12 preferred for precision die-cast parts. |

ADC12 aluminum alloy cannot be significantly strengthened through heat treatment like 6061 or 7075. Its high silicon content prevents major hardening, meaning its mechanical properties—tensile strength, hardness, and ductility—remain largely unchanged after heating. ADC12 is designed for high-pressure die casting, where its as-cast properties already meet most performance requirements.

Processing ADC12 aluminum alloy requires understanding its unique die-casting characteristics and machinability. Proper casting, CNC machining, and surface treatments ensure high-quality, durable parts with precise dimensions, suitable for automotive, electronics, and industrial applications.

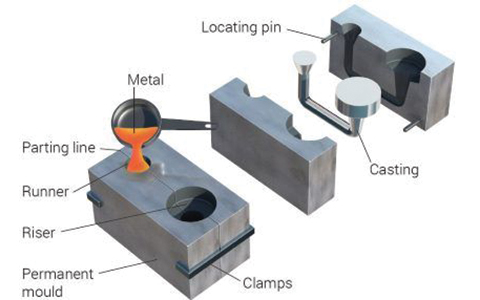

ADC12 is ideal for high-pressure die casting. The molten alloy is injected into precision steel molds under high pressure, producing complex shapes with thin walls and excellent dimensional accuracy. Its high silicon content ensures good flowability, minimal shrinkage, and low porosity.

Processing ADC12 Aluminum Alloy

Once cast, ADC12 parts can undergo CNC machining to achieve tight tolerances and intricate features. Drilling, milling, tapping, and turning are all possible due to its good machinability. Special cutting tools and lubricants optimized for aluminum reduce wear and prevent surface damage.

Surface Treatment and Coating

ADC12 surfaces can be enhanced with anodizing, powder coating, or painting to improve corrosion resistance, appearance, and wear protection. The alloy’s natural oxide layer supports these coatings, ensuring long-lasting results for both indoor and outdoor applications.

ADC12 aluminum alloy is recognized under multiple national and international standards, ensuring consistency in composition and properties for die-cast CNC machining parts. Understanding these standards helps manufacturers source compliant materials and maintain quality across industries.

National and International Standards

Equivalent Grades

| Standard |

Equivalent Grade |

Notes |

| JIS H5302 |

ADC12 | Original Japanese standard, widely adopted in Asia. |

| GB / Chinese Standard |

ZG-AlSi12Cu | Common in China for die-cast automotive parts. |

| ASTM B85 |

A383 / A384 | Internationally recognized casting alloy standard. |

| ISO |

AlSi12Cu | For global sourcing and quality assurance. |

ADC12 aluminum alloy is ideal for high-pressure die casting due to its excellent combination of flowability, dimensional stability, and corrosion resistance. Its high silicon content improves fluidity, allowing molten metal to fill intricate molds quickly and uniformly. The alloy’s low shrinkage reduces defects, while its natural hardness and strength support thin-walled, complex shapes.

Key Advantages for High-Pressure Die Casting:

Tip: ADC12 is preferred in automotive, electronics, and industrial components because it balances castability, strength, and corrosion resistance, making die-cast CNC machining parts cost-effective and reliable.

A leading automotive parts manufacturer approached VMT CNC Machining to produce high-precision engine brackets using ADC12 aluminum alloy. They required parts with complex geometry, tight tolerances, and excellent corrosion resistance for long-term reliability.

Challenge

Solution

VMT leveraged its expertise in die-cast ADC12 aluminum alloy CNC machining parts to:

Result

Tip: Selecting ADC12 aluminum for die-cast CNC machining parts ensures high-quality, durable, and cost-effective solutions for automotive and industrial applications. Early collaboration with experienced CNC machining factories helps avoid defects and reduces overall project costs.

VMT CNC Machining specializes in producing high-quality ADC12 aluminum alloy die-cast CNC machining parts. With advanced equipment, skilled engineers, and strict quality control, VMT delivers precision components for automotive, electronics, industrial, and consumer applications.

Services Offered

Why Choose VMT

Tip: Partnering with a skilled CNC machining factory like VMT ensures your ADC12 aluminum parts meet stringent performance requirements while keeping production efficient and cost-effective.

ADC12 aluminum alloy is a versatile, cost-effective material ideal for high-precision die-cast CNC machining parts. Its combination of excellent castability, corrosion resistance, dimensional stability, and good machinability makes it suitable for automotive, electronics, industrial equipment, and consumer applications.

While ADC12 has limitations, such as lower ductility and moderate heat-treatable strength, its advantages—lightweight, thermal conductivity, and precision casting—make it a preferred choice for mass production. By understanding its properties, applications, and comparisons with other alloys, manufacturers can make informed decisions that optimize performance, reduce production costs, and ensure long-term reliability.

1. What is the difference between 6061 and ADC12?

6061 is a heat-treatable wrought aluminum alloy known for high strength and ductility, while ADC12 is a die-cast aluminum alloy optimized for casting complex shapes. ADC12 has higher silicon for better fluidity, but it is more brittle than 6061.

2. What is the difference between ADC12 and A380?

ADC12 has higher silicon content and better corrosion resistance, making it ideal for durable, precision die-cast parts. A380 has slightly higher copper content, making it easier to cast very complex shapes but less resistant to corrosion.

3. Which is stronger, 6061 or 6063 aluminum?

6061 is stronger due to higher magnesium and silicon content and its heat-treatable properties. 6063 is more ductile and easier to extrude but has lower tensile strength.

4. Which is lighter, 6061 or 7075 aluminum?

6061 aluminum is slightly lighter (2.70 g/cm³) compared to 7075 (2.81 g/cm³), but 7075 is much stronger, making it preferable for high-stress applications.

5. What is 1350 grade aluminum?

1350 aluminum is a commercially pure alloy with excellent corrosion resistance and high electrical conductivity, commonly used in electrical and chemical applications.

6. What is ADC12 cast aluminum?

ADC12 cast aluminum is a high-silicon Al-Si-Cu die-cast alloy, widely used for automotive, electronics, and machinery parts that require precision, corrosion resistance, and good thermal conductivity.

7. Which is stronger, 5052 or 6061 aluminum?

6061 is stronger because it is heat-treatable and has higher magnesium content. 5052 is more corrosion-resistant and ductile but has lower tensile and yield strength.

8. What is the difference between ADC12 and AL6063?

ADC12 is designed for die casting with excellent fluidity and dimensional stability, while AL6063 is primarily an extruded alloy, known for good corrosion resistance and smooth finishes. 6063 is not suitable for high-pressure die casting.

9. What grade of ADC12 steel is used?

ADC12 is an aluminum alloy, not steel. Its standard grade is JIS H5302 ADC12, also equivalent to GB/ZG-AlSi12Cu or ASTM B85 Al-Si-Cu die-cast alloys.

10. Which aluminum grade is cheaper?

Die-cast alloys like ADC12 and A380 are generally more cost-effective for mass production of complex shapes. Wrought alloys such as 6061 or 7075 are more expensive due to machining and heat treatment.

11. What is the difference between 5754 aluminum and 5083 aluminum?

Both are marine-grade alloys with excellent corrosion resistance. 5083 has higher strength and better performance in extreme environments, while 5754 is easier to form and more cost-effective for lighter-duty applications.