15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

146 |

Published by VMT at Apr 23 2022

146 |

Published by VMT at Apr 23 2022

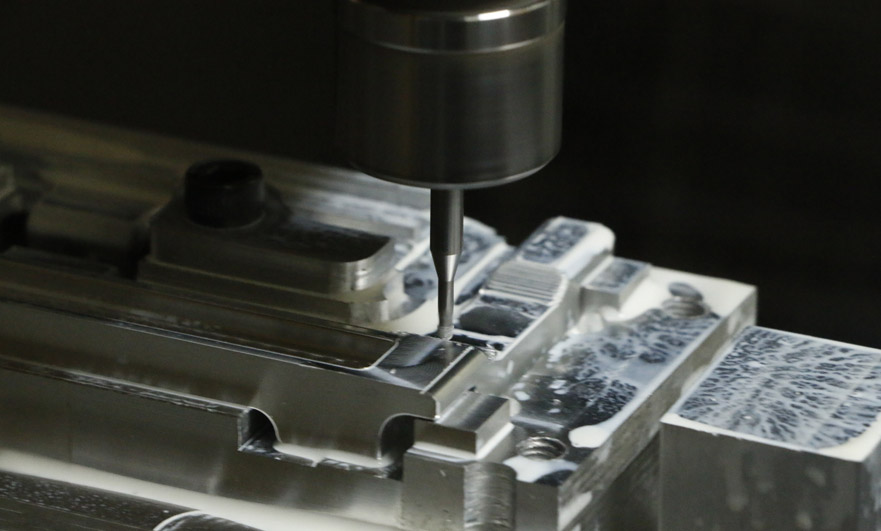

CNC machining: directly machining samples that meet the requirements from raw materials. The CNC machining speed is fast, and the surface quality of the samples is good. After the surface spraying, silk screen printing and electroplating processes are completed, the products are even more splendid than the products produced by opening the mold. Numerical control technology is applicable to a wide range of materials, and can use ABS, POC, PA, metal and other materials to process samples to meet different customer needs.

The feed route of CNC machining and finishing is basically carried out along the contour sequence of its CNC machined parts. Therefore, the focus of determining the feed route is to determine the feed route of rough machining and idle travel. Especially the samples processed with high quality and good density (unit: g/cm3 or kg/m3) engineering materials have unparalleled strength and toughness.

Demand for Small Batch CNC Machining

1. Product usage: For research projects, gift customization, souvenirs and other series of products, only a dozen or a few hundred sets are required, and there is no need to open molds for small batch CNC production, which can save costs and shorten cycle;

2. The market demand for the product is undetermined: For example, the newly developed CNC machining parts product has not been able to predict the market demand;

3. Product immaturity: if a CNC machining part product has just been developed, the product structure or appearance design is not reasonable enough;

4. Cost problem: In response to some companies or individuals encountering capital turnover problems or market risks in the early stage, there is no way to invest in mass production first, so they can only process small batches of CNC;

5. Product process problems: If the structure and size of a certain product is special, there is no way to open the mold, but there is a market, so it must be processed by CNC. CNC machining greatly reduces the number of tooling, and CNC machining parts with complex shapes do not require complex tooling. If you want to change the shape and size of the part, you only need to modify the CNC machining part program, which is suitable for new product development and modification.

CNC machining refers to machining with CNC machining tools.

CNC index-controlled machine tools are programmed and controlled by CNC machining language, usually G code. The CNC machining G code language tells the CNC machine tool which Cartesian position coordinates the machining tool adopts, and controls the feed rate and spindle speed of the tool, as well as functions such as tool changer and coolant.

VMT CNC Machining Manufacturer has 12 years of experience in manufacturing CNC machined parts and provides expertise in small batch custom CNC machined parts. All our precision CNC machining operations are subject to strict quality standards and our company is ISO9001 quality system, 16949 certified and SGS On-site factory audit.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!