15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

490 |

Published by VMT at Dec 17 2023

490 |

Published by VMT at Dec 17 2023

CNC turning services: widely used to improve manufacturing efficiency and precision

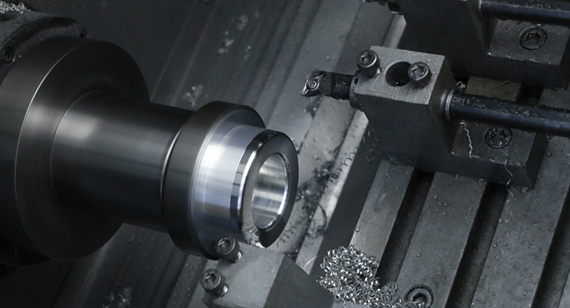

In today's era of high mechanical automation, CNC turning, as an important processing method, is widely used in various industries and fields. CNC turning service, that is, computer numerical control turning service, achieves high-precision and high-efficiency turning machining through precise digital control. This service has a wide range of applications in manufacturing, aerospace, medical equipment and other fields.

CNC turning service is a service that uses computer numerical control machine tools to perform turning processing. Through preset programs, CNC lathes can precisely control the movement of the turning tool to achieve the processing of complex shapes. This kind of service has the advantages of high precision, high efficiency, high flexibility, etc., and is widely used in various machinery manufacturing fields.

Manufacturing: CNC turning services are most widely used in the manufacturing industry. From automobile parts to precision instruments, almost all mechanical manufacturing processes are inseparable from CNC turning. This service can realize high-precision machining of complex shapes such as internal and external circles, cones, and curved surfaces, and improve product quality and performance.

Aerospace: The aerospace industry requires extremely high precision and performance of components, and CNC turning services can meet these requirements. Through the processing of lightweight and high-strength materials such as aluminum alloy and titanium alloy, parts that meet strict requirements can be manufactured to improve the performance and safety of aircraft.

Medical Equipment: The medical equipment industry also has very high requirements for precision and safety, and CNC turning services can meet these needs. By processing materials such as stainless steel and titanium alloys, ergonomic medical devices such as artificial joints and dental implants can be manufactured.

Application areas for CNC turning services include the manufacturing and machining of various parts. Here are some common CNC turned parts:

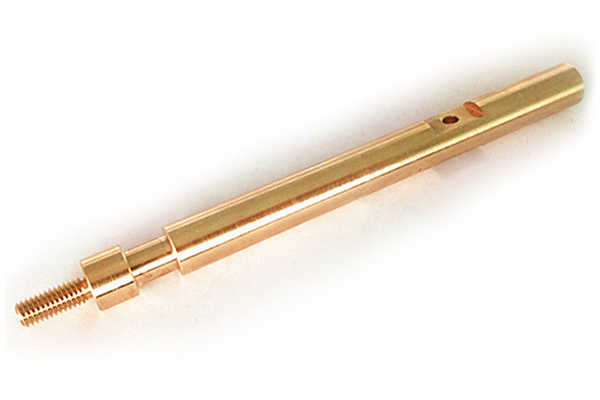

Shaft parts: CNC turning can be used to process various shaft parts, such as spindles, motor shafts, transmission shafts, etc. These parts usually require high precision and rigidity, and CNC turning can achieve high-precision machining through precise CNC programming and advanced tool materials.

Disc parts: Disc parts usually have the characteristics of thin wall and large diameter, such as flywheels, pulleys, etc. CNC turning can achieve high-efficiency processing through high-speed and high-feed speed processing, while ensuring the accuracy and quality of parts.

Sleeve parts: Sleeve parts usually require processing of the inner hole and outer circle, such as hydraulic cylinders, air cylinders, etc. CNC turning can achieve high-precision inner hole and outer circle processing through precise CNC programming and advanced tool materials, while ensuring the accuracy requirements such as coaxiality and cylindricity of parts.

Complex curved surface parts: Complex curved surface parts usually require multi-axis simultaneous processing, such as propellers, blades, etc. CNC turning can achieve efficient processing of complex curved surface parts through multi-axis linkage processing, while ensuring the accuracy and quality of the parts.

High-precision parts: For parts that require high-precision processing, such as precision instruments, aerospace parts, etc., CNC turning can achieve high-precision processing through precise CNC programming and advanced tool materials while ensuring the stability and reliability of the parts.

In short, CNC turning services are widely used in the manufacturing and processing of parts in various fields. They can achieve high-precision, high-efficiency, and high-flexibility processing requirements, improve product quality and performance, and reduce production costs and risks.

High precision: CNC turning services can achieve micron-level machining accuracy, ensuring minimal size and shape errors of parts and improving product performance and quality.

High efficiency: CNC lathes have a high degree of automation, which can reduce the time and energy of manual operations and improve production efficiency. At the same time, by optimizing processing parameters and programs, fast turning and efficient processing can be achieved.

High flexibility: CNC lathes can process different types and shapes by changing tools and converting programs. This makes CNC turning services highly flexible and able to adapt to different market demands and production conditions.

Reduce costs: CNC turning services are highly automated, which can reduce labor costs and production costs. At the same time, by optimizing the processing process and improving production efficiency, cost reduction and benefit maximization can be achieved.

Improve competitiveness: In today's fierce market competition, by using advanced CNC turning technology, companies can produce high-quality, high-performance products and increase their market share and competitiveness.

As an advanced processing method, CNC turning services are widely used in manufacturing, aerospace, medical equipment and other fields. Through the characteristics of high precision, high efficiency and high flexibility, CNC turning services provide enterprises with better manufacturing solutions, improve product quality and performance, and reduce production costs and risks. With the continuous development of technology, the future of CNC turning services will be broader and more flexible, providing more opportunities and support for the development of all walks of life.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!