15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

102 |

Published by VMT at Nov 30 2023

102 |

Published by VMT at Nov 30 2023

Swiss CNC Machining: Precision Engineering at its Zenith

Swiss CNC machining, originating in Switzerland, is a cutting-edge precision CNC machining technique known for its unparalleled accuracy and efficiency. Unlike conventional machining methods, Swiss CNC machining revolves around a sliding headstock lathe that holds and rotates the workpiece. Here's an overview:

Specialized Design:

The hallmark of Swiss CNC machining lies in its specialized design featuring a sliding headstock and guide bushing. This design ensures precise control and stability during the machining process.

Reduced Vibration and Flexibility:

The rotating guide bushing minimizes vibration and supports the workpiece, enabling the machining of long and slender parts with exceptional accuracy.

Simultaneous Machining:

Swiss CNC machines excel in simultaneous machining with multiple tools operating on the workpiece. This multifunctionality accelerates production while maintaining precision.

Ideal for Small, Complex Parts:

Swiss CNC machining is particularly suitable for manufacturing small, intricate parts with tight tolerances. This makes it a preferred choice in industries such as medical, aerospace, and electronics.

Materials Versatility:

The technique accommodates a wide range of materials, including metals, plastics, and composites, offering versatility in manufacturing various components.

Automation Integration:

Many Swiss CNC machines incorporate automation features, further enhancing efficiency by reducing manual intervention and ensuring consistent quality.

Reduced Lead Times:

The simultaneous machining capabilities and reduced setup times contribute to shorter lead times, making Swiss CNC machining a time-efficient solution.

Applications Across Industries:

While initially developed for watchmaking in Switzerland, Swiss CNC machining has evolved to become a cornerstone in industries requiring high-precision CNC machining components, such as medical device manufacturing and aerospace.

In essence, Swiss CNC machining represents the pinnacle of precision and efficiency, offering manufacturers a competitive edge in producing intricate parts with exceptional accuracy.

Swiss CNC Machining Centers: Tailored Solutions for Medical Device Components

Swiss CNC machining centers, with their precision and versatility, are particularly well-suited for crafting a wide range of medical device components. These machines excel in producing intricate and high-precision CNC machining parts crucial for the healthcare industry. Here are some medical device components ideally processed using Swiss CNC machining:

Orthopedic Implants:

Swiss CNC machining is employed for crafting orthopedic implants, ensuring precise shapes and dimensions for joint replacements and orthopedic devices.

Surgical Instruments:

The production of surgical instruments benefits from Swiss CNC machining, delivering precision in the manufacturing of tools used in various medical procedures.

Dental Components:

Dental applications leverage Swiss CNC machining for manufacturing dental implants, abutments, crowns, and other precision components used in dentistry.

Microfluidic Devices:

For medical diagnostics and research, Swiss CNC machining is crucial in creating microfluidic devices, enabling precise control of fluids on a microscopic scale.

Endoscopic Components:

Swiss CNC machining ensures the intricate and precise manufacturing of endoscopic components, contributing to advancements in minimally invasive surgical procedures.

Prosthetic Devices:

Crafting prosthetic devices demands high precision, and Swiss CNC machining delivers accuracy in creating components for artificial limbs and prosthetics.

Cardiac Implant Components:

The production of components for cardiac implants, such as pacemakers and defibrillators, benefits from the precision offered by Swiss CNC machining.

Neurosurgical Tools:

Swiss CNC machining plays a crucial role in crafting neurosurgical tools, including components for devices used in delicate brain and spinal procedures.

Ophthalmic Instruments:

Components for ophthalmic instruments, such as those used in eye surgeries and treatments, are manufactured with precision using Swiss CNC machining.

Diagnostic Equipment Parts:

Precision components for diagnostic equipment, including imaging devices and analysis tools, are efficiently produced using Swiss CNC machining.

The inherent capabilities of Swiss CNC machining, including multi-axis simultaneous machining and tight tolerance control, make it an ideal choice for the intricate and demanding requirements of medical device manufacturing. These machines contribute significantly to the advancement of healthcare technology by ensuring the production of high-quality and precise CNC machining components.

Ideal Applications for Swiss CNC Machining: Precision Beyond Boundaries

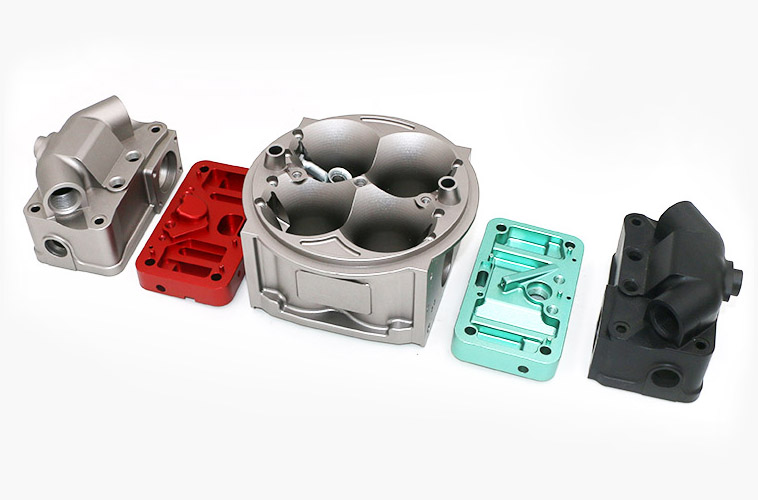

Swiss CNC machining is renowned for its exceptional precision and efficiency, making it a preferred choice for various industries. Here are the types of parts that Swiss CNC machining excels in producing:

Small and Complex Components:

Swiss CNC machining is tailor-made for the production of small and intricate parts that demand high precision. This includes components with intricate geometries and tight tolerances.

The medical industry benefits significantly from Swiss CNC machining, especially for crafting surgical instruments, implantable devices, and other intricate components crucial for healthcare applications.

Aerospace Components:

Swiss CNC machining finds extensive use in aerospace for manufacturing precision components like turbine parts, connectors, and aerospace fasteners, where accuracy and reliability are paramount.

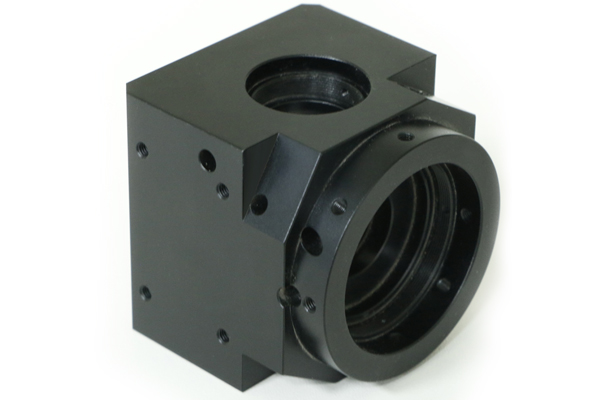

Electronics and Microtechnology:

The electronic industry leverages Swiss CNC machining for crafting intricate parts such as connectors, sensors, and other microtechnology components where precision and miniaturization are essential.

Watchmaking and Timepieces:

Originating in watchmaking, Swiss CNC machining remains indispensable for crafting the intricate components of watches, ensuring accuracy in timekeeping mechanisms.

In the automotive sector, Swiss CNC machining is employed for the production of precision components like fuel injectors, connectors, and intricate parts within engines and transmissions.

Defense and Firearms:

The defense industry benefits from Swiss CNC machining for manufacturing firearm components, optics, and other critical parts requiring precision and reliability.

Swiss CNC machining is instrumental in crafting optical components such as lenses, camera parts, and other precision optics where meticulous accuracy is crucial.

Dental Implants and Instruments:

Dental applications benefit from the precision of Swiss CNC machining, producing dental implants, prosthetics, and precision instruments used in dentistry.

Customized Fasteners:

The production of customized, high-precision fasteners for various industries, ensuring reliability and stability in assemblies.

In summary, Swiss CNC machining's versatility and precision make it an ideal choice for manufacturing small, intricate, and high-precision components across a diverse range of industries.

Swiss CNC Machining: Achieving Minimal Tolerances with Precision Excellence

Swiss CNC machining is renowned for its capability to achieve incredibly low tolerances, a crucial factor in industries demanding utmost precision. The minimum achievable tolerances with Swiss CNC machining typically range from:

Diameter Tolerances:

Swiss CNC machining excels in achieving diameter tolerances as low as a few micrometers, ensuring precise control over the size of cylindrical components.

Length Tolerances:

The length tolerances with Swiss CNC machining can be minimized to fractions of a millimeter, providing accuracy in the production of small and intricate parts.

Surface Finish Tolerances:

Achieving exceptional surface finishes is a forte of Swiss CNC machining, with tolerances reaching down to the sub-micron level. This is vital for applications where smooth and flawless surfaces are imperative.

Positional Tolerances:

Swiss CNC machining ensures precise positioning of features, with positional tolerances often measured in fractions of a millimeter or even finer, facilitating the creation of complex and accurately aligned components.

Angular Tolerances:

The angular tolerances achievable with Swiss CNC machining are remarkable, allowing for the production of components where angular accuracy is critical.

Concentricity and Symmetry:

Swiss CNC machining can achieve high levels of concentricity and symmetry, ensuring that rotating components and assemblies meet stringent standards.

Multi-Axis Simultaneous Machining:

The multi-axis capabilities of Swiss CNC machines contribute to achieving minimal tolerances by allowing simultaneous machining from different angles, enhancing precision in complex geometries.

Repeatability:

Swiss CNC machining offers exceptional repeatability, ensuring that each part produced adheres consistently to the specified tolerances over multiple production runs.

The exact minimum tolerances achievable may vary based on factors such as material, part complexity, and machine specifications. However, Swiss CNC machining stands out for its ability to consistently deliver precision at levels that meet or exceed the stringent requirements of industries like medical, aerospace, and electronics. This precision is a testament to the meticulous engineering and advanced technology embedded in Swiss CNC machining centers.

Learn about Swiss CNC machining services Whether you are in the development phase or looking to optimize production, you can take advantage of the precision and versatility that Swiss CNC machining offers, making it ideal for manufacturing small, complex and high-precision CNC machining parts across a variety of industries.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!