15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

117 |

Published by VMT at Dec 02 2023

117 |

Published by VMT at Dec 02 2023

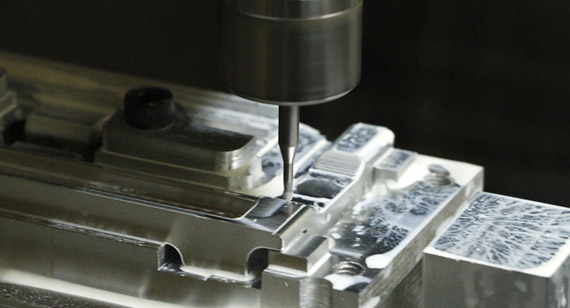

Understanding the High Manufacturing Cost of Titanium CNC Machined Parts

The elevated manufacturing cost of titanium CNC machined parts can be attributed to several factors that collectively contribute to the overall expense. Here's an overview of why the production cost of titanium CNC machined parts tends to be high:

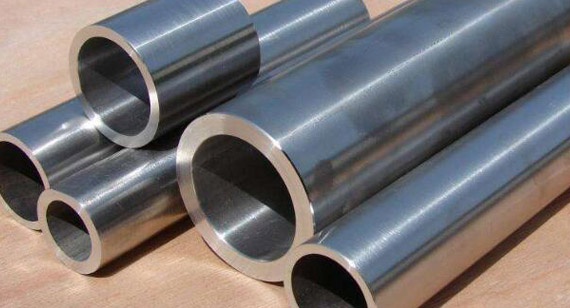

Material Cost:

Titanium is an expensive material compared to more common metals like aluminum or steel. The raw material cost significantly influences the overall manufacturing expense.

Material Hardness:

Titanium is known for its high strength and hardness. Machining this material requires specialized tools and cutting techniques, leading to increased tool wear and replacement costs.

Tool Wear and Tool Replacement:

CNC Machining titanium is abrasive, causing faster wear and tear on cutting tools. Frequent tool changes and the use of high-performance tooling contribute to increased production costs.

Low Machinability:

Titanium has lower machinability compared to some other metals. Its propensity to work-harden during machining necessitates careful consideration of cutting parameters, slowing down the CNC machining process.

Energy Consumption:

Titanium's resistance to deformation and high melting point require more energy during the CNC machining process. This increased energy consumption contributes to higher operating costs.

Coolant and Lubrication Requirements:

Titanium machining often requires extensive use of coolants and lubricants to dissipate heat generated during cutting. Managing these fluids adds to the operational costs.

Specialized Equipment:

Titanium CNC machining demands robust and specialized CNC machines with features designed to handle the challenges posed by this material. The investment in such equipment adds to the overall manufacturing cost.

Post-Processing:

Titanium CNC machining parts often require additional post-processing steps, such as heat treatment or surface finishing, to meet specific performance and aesthetic requirements. These additional steps contribute to the overall cost.

Scrap and Waste:

The difficulty in CNC machining titanium increases the likelihood of scrap and waste during the manufacturing process. Minimizing waste requires precision and meticulous control, adding complexity and cost.

Expertise and Skilled Labor:

Machining titanium demands a high level of expertise. Skilled machinists who understand the intricacies of working with titanium are essential, and their expertise often comes at a premium, contributing to labor costs.

Order Size

The order quantity will also affect the cost of titanium CNC machining parts. This is very simple. The greater the purchase quantity, the greater the cost savings! There is no MOQ requirement in VMT, we treat it equally whether it is a small batch or a large batch.

While titanium offers exceptional qualities, including high strength-to-weight ratio and corrosion resistance, its challenging machinability and associated costs make it a more expensive material to work with compared to others. Despite the higher CNC machining manufacturing costs, the unique properties of titanium often justify its use in critical applications where its specific attributes are indispensable.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!