15 years one-stop China custom CNC machining parts factory

1285 |

Published by VMT at Sep 28 2021

1285 |

Published by VMT at Sep 28 2021

The term "Citizen Swiss Automatic Lathe" refers to a type of precision lathe manufactured by Citizen Instruments Inc., a Japanese company known for its expertise in watchmaking and precision engineering. The Citizen Swiss Automatic Lathe combines Swiss watchmaking technology with Japanese precision manufacturing to create a high-quality automatic lathe.

Designed for precision machining applications, the Citizen Swiss Automatic Lathe is known for its exceptional accuracy, reliability, and efficiency. It incorporates advanced features and technologies that enable it to produce intricate components with tight tolerances and excellent surface finishes.

The Citizen Swiss Automatic Lathe is widely used in the watchmaking industry for manufacturing watch components such as watch cases, dials, hands, and movement parts. Its precise movements and ability to work with various materials, including metals and synthetic materials, make it a versatile tool for creating intricate and finely crafted watch components.

The integration of Swiss and Japanese engineering expertise in the Citizen Swiss Automatic Lathe ensures the highest level of quality and performance. With its advanced capabilities, this lathe plays a crucial role in the production of high-end watches, where precision and craftsmanship are paramount.

Citizen Swiss CNC machining involves the use of a Swiss-type lathe, which differs from conventional lathes in several ways. The key feature of a Swiss-type lathe is the addition of a guide bushing located close to the cutting tool. This guide bushing provides support and stability to the workpiece, allowing for precise machining operations.

The Swiss CNC machining process is particularly suitable for long and slender parts, where maintaining tight tolerances and high surface finishes are critical. It is commonly used in industries such as medical, aerospace, watchmaking, and electronics, where intricate and small parts are required.

Swiss CNC machining offers several advantages that make it a preferred choice for the production of small and complex parts:

Precision and Accuracy: The incorporation of a guide bushing and the ability to control multiple rotating tools result in exceptional precision and tight tolerances, ensuring high-quality and consistent parts.

Versatility: Swiss CNC machines can perform a wide range of machining operations, including turning, milling, drilling, and threading, in a single setup. This versatility eliminates the need for multiple machines and reduces production time.

Enhanced Surface Finish: The combination of precise tooling and the support provided by the guide bushing allows for excellent surface finishes, reducing the need for additional finishing processes.

Material Savings: Swiss CNC machines excel in minimizing material waste due to their ability to perform close-tolerance machining near the guide bushing, reducing scrap and material costs.

Efficiency and Productivity: The integration of bar feeders enables uninterrupted production, leading to increased efficiency and productivity. Swiss CNC machines can also handle high-volume production runs with ease.

Complex Geometry: Swiss CNC machining is well-suited for creating parts with intricate geometries, such as threads, cross-holes, and small-diameter features.

The Swiss CNC machining process typically involves the following steps:

Material Loading: A long bar of raw material is loaded into the bar feeder, which automatically feeds the material into the machine.

Workpiece Preparation: The bar is clamped by the collet in the sliding headstock, ensuring stability and precision during machining.

Tool Setup: Rotating tools, such as drills, end mills, and thread taps, are set up in the tool stations according to the machining requirements.

Machining Operations: The Swiss CNC machine begins the machining process, with the rotating tools performing various operations such as turning, milling, drilling, and threading. The guide bushing provides support and stability to the workpiece, ensuring accurate and precise machining.

Simultaneous Operations: One of the key advantages of Swiss CNC machining is the ability to perform simultaneous operations on different parts of the workpiece. While the main spindle rotates and performs primary machining, the rotating tools can perform secondary operations on the workpiece simultaneously.

Chip Control: Swiss CNC machines incorporate efficient chip control mechanisms to ensure the uninterrupted flow of chips away from the workpiece. High-pressure coolant is often employed to assist in chip evacuation, keeping the machining area clean and preventing chip buildup.

Quality Control: Throughout the machining process, quality control measures are implemented to ensure that the parts meet the specified tolerances and quality standards. This may involve in-process inspections, dimensional measurements, and surface finish evaluations.

While Swiss Automatic Lathes offer numerous advantages, they also have a few limitations or considerations to keep in mind. Here are some of the potential drawbacks of using a Citizen Swiss Automatic Lathe or similar machines:

Higher Initial Cost: Swiss Automatic Lathes are generally more expensive compared to traditional lathes. Their advanced technology, precision components, and sophisticated control systems contribute to the higher initial investment required. Therefore, the cost of acquiring and setting up a Swiss Automatic Lathe can be a significant consideration for smaller businesses or those with limited budgets.

Complex Programming and Setup: Operating a Swiss Automatic Lathe requires specialized knowledge and skills. Programming these machines can be complex, especially for intricate parts with multiple axes of movement. The setup process, including tooling, workpiece positioning, and synchronization of various machining operations, demands expertise and experience. Training and expertise in programming and operating Swiss Automatic Lathes are necessary to fully utilize their capabilities.

Limited Workpiece Size: Swiss Automatic Lathes are optimized for machining smaller to medium-sized parts. The sliding headstock design and the close proximity of cutting tools to the workpiece limit the maximum diameter and length of the components that can be machined. Larger workpieces may require alternative machining methods or different types of lathes.

Higher Maintenance Requirements: The precision and complexity of Swiss Automatic Lathes often translate to more demanding maintenance requirements. Regular maintenance, including lubrication, calibration, and inspection of critical components, is essential to ensure optimal performance and accuracy. Adequate maintenance and a well-trained maintenance staff are necessary to keep the machines in optimal working condition.

Production Volume Considerations: While Swiss Automatic Lathes are highly efficient for high-volume production, they may not be as cost-effective for low-volume or prototyping applications. The setup and programming time required for each unique part can make them less efficient for small batch sizes. Other machining methods, such as manual lathes or CNC milling, may be more suitable for low-volume or one-off production.

Material Limitations: Although Swiss Automatic Lathes can handle a wide range of materials, there may be limitations in terms of the hardness, toughness, or heat resistance of certain materials. Some exotic or highly abrasive materials may require specialized tooling or additional considerations to achieve the desired machining results.

While these limitations exist, they can be mitigated or outweighed by the significant advantages offered by Swiss Automatic Lathes. Careful consideration of these factors, along with an understanding of the specific production requirements, can help determine the suitability and cost-effectiveness of using a Swiss Automatic Lathe for a particular application.

Citizen Swiss Automatic Lathes and conventional lathes (also known as general-purpose lathes) have distinct differences in terms of design, functionality, and applications. Here are the key differences between Citizen Swiss Automatic Lathes and conventional lathes:

Design and Construction: Citizen Swiss Automatic Lathes feature a sliding headstock design, where the workpiece remains stationary, and the cutting tools are mounted on sliding tool holders that move along the length of the workpiece. In contrast, conventional lathes have a fixed headstock, and the workpiece rotates while the cutting tools remain stationary or move manually.

Automation and Precision: Swiss Automatic Lathes are designed for high precision and often incorporate advanced automation features. They have CNC (Computer Numerical Control) capabilities, allowing for precise control of cutting tool movements, automated tool changes, and sophisticated programming options. Conventional lathes, on the other hand, are manually operated or have simpler controls, which may require more manual intervention and rely on the operator's skill for precision.

Complexity of Machining: Swiss Automatic Lathes excel in machining complex and intricate parts. With their sliding headstock design and multi-axis capabilities, they can perform simultaneous machining operations, such as turning, milling, drilling, and threading, in a single setup. Conventional lathes are generally better suited for simpler turning operations and may require additional setups or equipment for secondary machining processes.

Suitability for Small Parts: Swiss Automatic Lathes are highly suitable for machining small parts with tight tolerances, often found in industries like watchmaking and medical device manufacturing. The sliding headstock design allows for precise machining of intricate features on small workpieces. Conventional lathes, while capable of machining small parts, may not offer the same level of precision and efficiency for intricate components.

Production Volume and Efficiency: Swiss Automatic Lathes are designed for high-volume production and can achieve efficient and continuous machining processes. They excel in reducing setup times, minimizing material waste, and optimizing production throughput. Conventional lathes are more versatile and can handle a wide range of machining tasks but may require more manual intervention, making them better suited for low to medium production volumes or prototyping.

Cost Considerations: Swiss Automatic Lathes are generally more expensive than conventional lathes due to their advanced technology, precision components, and automation capabilities. The higher initial investment of Swiss Automatic Lathes may be justified for high-volume production and complex machining requirements. Conventional lathes offer a more cost-effective solution for simpler turning operations or lower production volumes.

In summary, Citizen Swiss Automatic Lathes offer advanced automation, precision, and versatility for machining small, complex parts with high efficiency and accuracy. Conventional lathes are more versatile and suitable for a broader range of machining tasks but may not provide the same level of precision and automation capabilities as Swiss Automatic Lathes. The choice between the two depends on the specific machining requirements, production volume, and budget considerations.

Citizen Swiss Automatic Lathes are particularly well-suited for machining small, intricate, and high-precision components. Here are some types of parts that are commonly processed using Citizen Swiss Automatic Lathes:

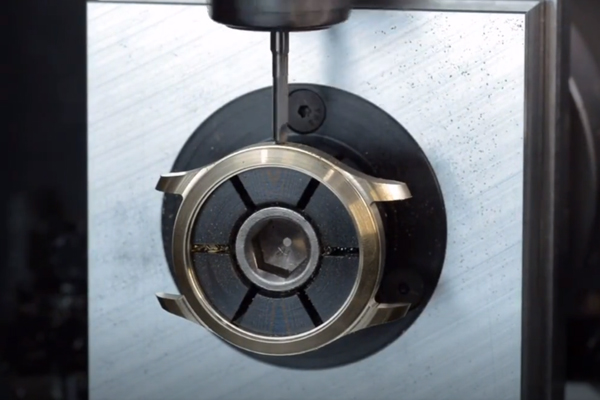

Watch Components: Swiss Automatic Lathes have a strong historical association with the watchmaking industry. They are ideal for manufacturing various watch components, such as watch cases, bezels, crowns, dials, hands, and gears. The precise machining capabilities of Swiss Automatic Lathes enable the creation of intricate details and tight tolerances required for watch movements.

Medical and Dental Implants: The medical and dental industries demand highly precise and intricate parts, such as orthopedic implants, dental implants, bone screws, and surgical instruments. Swiss Automatic Lathes excel in machining these complex components with precise dimensions, intricate features, and smooth surface finishes.

Electronics and Connectors: Swiss Automatic Lathes are widely used in the production of electronic components, including connectors, pins, sockets, and terminals. The machines can achieve precise machining of small features, such as threads, grooves, and contact points, required for reliable electrical connections.

Automotive Parts: Citizen Swiss Automatic Lathes are also employed in the automotive industry for manufacturing various components, including fuel injectors, connectors, sensors, valves, and piston pins. The machines' ability to handle complex geometries and tight tolerances ensures the production of high-quality automotive parts.

Aerospace Components: The aerospace industry requires components with exceptional precision, reliability, and resistance to harsh environments. Swiss Automatic Lathes play a crucial role in machining aerospace parts such as turbine blades, fuel system components, hydraulic fittings, and aerospace connectors. The machines' accuracy and capability to work with challenging materials make them well-suited for aerospace applications.

Precision Mechanical Components: Citizen Swiss Automatic Lathes are widely used for machining precision mechanical parts, including screws, nuts, bolts, shafts, and bushings. These components often require tight tolerances, fine threads, and intricate features, all of which can be achieved using the precision capabilities of Swiss Automatic Lathes.

These are just a few examples of the types of parts that can be effectively machined using Citizen Swiss Automatic Lathes. Their ability to handle small workpieces, achieve high precision, and perform multiple machining operations in a single setup makes them an excellent choice for industries that require intricate and high-quality components.

Swiss Automatic Lathes are renowned for their exceptional precision in machining. The accuracy and tolerances that can be achieved depend on various factors, including the machine's design, the quality of components, the cutting tools used, and the expertise of the operator. Here are some general guidelines regarding the precision that can be achieved with Swiss Automatic Lathes:

Dimensional Accuracy: Swiss Automatic Lathes can achieve dimensional accuracy within microns (μm) or even sub-micron levels. With proper setup, calibration, and tooling, these machines can consistently hold tight tolerances, ensuring precise dimensions and geometries of machined parts.

Surface Finishes: Swiss Automatic Lathes can produce excellent surface finishes on machined parts. The use of high-quality cutting tools, appropriate machining parameters, and proper toolpath strategies contribute to achieving smooth and fine surface finishes. Depending on the material and machining parameters, surface finishes in the range of Ra 0.4 to Ra 0.8 micrometers can often be achieved.

Positioning Accuracy: Swiss Automatic Lathes incorporate precise positioning systems, allowing for accurate tool movement and workpiece indexing. The positioning accuracy of these machines is typically within a few microns, ensuring the precise location and alignment of machining operations.

Repeatability: Swiss Automatic Lathes demonstrate excellent repeatability, meaning they can consistently reproduce the same machining results. The machines can repeatedly position cutting tools and perform machining operations with high accuracy, ensuring consistent part quality throughout production runs.

It's important to note that achieving the highest level of precision with Swiss Automatic Lathes requires careful attention to setup, programming, tool selection, and maintenance. Factors such as the complexity of the part, the material being machined, and the desired tolerances will also influence the achievable precision. Additionally, the expertise and experience of the operator play a significant role in maximizing the machine's precision capabilities.

By leveraging the advanced capabilities of Swiss Automatic Lathes and implementing best practices in machining processes, it is possible to achieve exceptional levels of precision in the range of a few microns or even sub-microns.

Swiss CNC screw machining, also known as Swiss-type turning, is widely recognized for its ability to efficiently and accurately produce high-quality screws and other small precision components. The process combines the advantages of CNC technology with the unique features of Swiss-style lathes, resulting in exceptional screw machining capabilities. Here are some key aspects of Swiss CNC screw machining:

Small Diameter Screws: Swiss CNC screw machining excels in producing small-diameter screws, typically ranging from a few millimeters to around 25 millimeters. The machines are specifically designed to handle long, slender workpieces with excellent stability and precision.

High Precision and Tight Tolerances: Swiss CNC screw machines can achieve tight tolerances and high precision in screw manufacturing. The machines incorporate multiple axes of movement, allowing for simultaneous machining operations, including turning, threading, drilling, and milling. This enables precise control over dimensions, threads, and other critical features of the screws.

Complex Geometries: Swiss CNC screw machining is capable of producing screws with complex geometries and intricate features. With the ability to use live tooling and perform multi-axis machining, the machines can create various types of screw heads, such as Phillips, Torx, and hexagonal, as well as custom-designed features like flanges or knurls.

Efficiency and Productivity: Swiss CNC screw machines offer high efficiency and productivity, especially for high-volume production. The machines feature automatic bar feeders that can continuously feed raw material, minimizing downtime for material reloading. The combination of simultaneous machining operations, quick tool changes, and optimized programming contributes to faster cycle times and increased output.

Versatility and Material Compatibility: Swiss CNC screw machines can work with a wide range of materials, including stainless steel, aluminum, brass, titanium, and various alloys. They accommodate different material properties and provide the flexibility to produce screws for diverse industries and applications.

Quality Control and Consistency: Swiss CNC screw machining ensures excellent quality control and consistency throughout the production process. The machines offer advanced monitoring and feedback systems to detect and correct any deviations or errors, resulting in consistent and reliable screw manufacturing.

Swiss CNC screw machining is widely adopted in industries that require precision screws, such as automotive, aerospace, electronics, medical devices, and general manufacturing. The process's combination of precision, efficiency, and versatility makes it an ideal choice for producing high-quality screws with tight tolerances and complex geometries.

CNC Swiss lathes, also known as Swiss-type lathes or Swiss screw machines, find extensive applications in various industries due to their precision, versatility, and efficiency. Here are some common applications of CNC Swiss lathe parts:

Medical Devices: CNC Swiss lathes are widely used in the medical industry for manufacturing critical components of medical devices. These include surgical instruments, orthopedic implants, dental implants, bone screws, and specialized medical connectors. The high precision and tight tolerances achieved by CNC Swiss lathes ensure the quality and reliability of these medical components.

Electronics and Electrical Connectors: CNC Swiss lathes play a crucial role in producing electrical connectors, pins, sockets, and terminals used in the electronics industry. The machines' ability to machine small and intricate features, such as threads and contact points, ensures reliable electrical connections in devices ranging from consumer electronics to industrial machinery.

Automotive Components: CNC Swiss lathes are employed in the automotive industry for manufacturing various precision components. These include fuel injectors, valve bodies, connectors, sensor housings, and piston pins. The machines' capability to handle complex geometries and work with a wide range of materials makes them suitable for automotive applications that require high precision and reliability.

Aerospace Parts: CNC Swiss lathes are extensively utilized in the aerospace industry for machining critical components. These include turbine blades, aerospace connectors, hydraulic fittings, fuel system components, and actuators. The machines' ability to achieve tight tolerances and produce intricate features contributes to the high performance and safety of aerospace systems.

Watchmaking: CNC Swiss lathes have a longstanding association with the watchmaking industry. They are used for manufacturing various watch components, such as watch cases, crowns, bezels, dials, hands, and gears. The precision and intricate detailing achieved by CNC Swiss lathes contribute to the exceptional craftsmanship and accuracy of luxury timepieces.

General Precision Machining: CNC Swiss lathes are employed for producing a wide range of precision components used in industries such as telecommunications, optics, defense, and general manufacturing. These components can include screws, bolts, nuts, shafts, bushings, and other intricate parts that require high accuracy and tight tolerances.

The applications of CNC Swiss lathe parts are diverse and span across industries that demand high precision, complex geometries, and reliable performance. By leveraging the capabilities of CNC Swiss lathes, manufacturers can achieve exceptional quality and meet the stringent requirements of various sectors.

The time and cost associated with CNC Swiss lathe machining depend on several factors, including the complexity of the part, the material being machined, the desired tolerances, the machine setup, and the expertise of the operator. Here are some considerations regarding time and cost in CNC Swiss lathe machining:

Setup Time: The setup time involves preparing the machine, loading the raw material, and setting up the necessary tooling. It includes tasks such as tool changes, fixture setup, and program loading. The setup time can vary depending on the complexity of the part and the familiarity of the operator with the specific job requirements.

Machining Time: The machining time refers to the actual time required to perform the machining operations on the CNC Swiss lathe. It includes turning, drilling, threading, milling, and any other required operations. The machining time depends on factors such as the part complexity, the material being machined, the desired surface finish, and the cutting parameters selected. Complex parts with intricate features may require longer machining times compared to simpler components.

Material and Tooling Costs: The cost of materials and cutting tools used in CNC Swiss lathe machining is a consideration. Different materials have varying costs, and the selection of cutting tools can also impact the overall cost. Factors such as tool life, tool quality, and the number of tools required for a specific job will influence the cost.

Labor Costs: Labor costs are associated with the expertise and time required for programming, machine setup, and operating the CNC Swiss lathe. Skilled operators familiar with the machine and the specific part requirements can optimize the machining process, reducing the overall labor costs. The complexity of the part and the need for specialized programming or setup may also impact labor costs.

Quality Control: Quality control measures, such as inspection and testing of the machined parts, add to the overall time and cost. Ensuring that the parts meet the required specifications and tolerances may involve additional inspection steps, such as dimensional checks, surface finish assessment, and functional testing.

It's important to note that the time and cost considerations can vary significantly based on the specific requirements of each machining project. Complex parts with tight tolerances and difficult-to-machine materials will typically require more time and incur higher costs compared to simpler components. Additionally, optimizing the machining process, streamlining setups, and maximizing the efficiency of the CNC Swiss lathe can help reduce both time and cost.

To get an accurate estimation of the time and cost for a specific CNC Swiss lathe machining project, it is advisable to consult with a qualified machining provider who can evaluate the specific requirements and provide a detailed quote based on the project's scope and complexity.

The Swiss automatic lathes by Citizen Machinery, commonly known as Citizen Swiss-type lathes or Swiss screw machines, are highly versatile and suitable for machining a wide range of materials. Some of the materials that the Citizen Swiss automatic lathes are well-suited for include:

Metals: The Citizen Swiss-type lathes are capable of machining various metals, including stainless steel, carbon steel, aluminum, brass, copper, titanium, and alloys such as Inconel and Monel. These machines offer excellent cutting performance and can handle the challenges associated with metal machining, such as high heat and hardness.

Plastics: The Citizen Swiss automatic lathes are also effective in machining different types of plastics, such as ABS (Acrylonitrile Butadiene Styrene), nylon, polyethylene, polycarbonate, PEEK (Polyether Ether Ketone), and PTFE (Polytetrafluoroethylene). They provide precise control and minimize the risk of material deformation or damage during machining.

Exotic Materials: The exceptional rigidity and stability of the Citizen Swiss-type lathes allow for machining of exotic materials like ceramics and composites. These materials often have unique properties and require specialized machining processes, and the precision capabilities of the machines enable the production of high-quality components from such materials.

The specific model and configuration of the Citizen Swiss automatic lathe may also influence the suitability for different materials. Different machine specifications, such as spindle speed, cutting tool options, and coolant systems, can be optimized to accommodate specific material characteristics and machining requirements.

It's worth noting that while Citizen Swiss automatic lathes can effectively machine a wide range of materials, each material may have its own unique challenges and considerations. Factors such as tool selection, cutting parameters, and coolant requirements may need to be adjusted accordingly to achieve optimal machining results for each material type.

To determine the best approach for machining a specific material using a Citizen Swiss automatic lathe, it is recommended to consult with machining experts or tooling specialists who can provide guidance based on their experience and knowledge of the machine capabilities.

When working with Swiss CNC lathes, there are several important considerations and techniques to keep in mind for successful machining operations. Here are some key points to consider when using Swiss CNC lathes:

Proper Workpiece Preparation: Ensure that the workpiece is properly prepared for machining on a Swiss CNC lathe. This includes selecting the appropriate material, properly securing the workpiece in the collet or guide bushing, and verifying the dimensional accuracy and cleanliness of the workpiece.

Tooling Selection and Setup: Choose the right cutting tools based on the material being machined, the desired features, and the specific requirements of the job. Ensure that the tools are properly mounted, aligned, and set up for optimal cutting performance.

Optimized Toolpaths: Develop efficient toolpaths that minimize unnecessary tool movements, reduce cycle times, and maximize productivity. Optimize the toolpaths to minimize tool changes and ensure smooth transitions between machining operations.

Workpiece Support: Pay attention to the workpiece support and stability during machining. Properly support long or slender workpieces using guide bushings or other support mechanisms to prevent vibration and maintain machining accuracy.

Chip Management: Effective chip management is crucial in Swiss CNC lathe machining. Use appropriate chip breakers, chip evacuation techniques, and coolant application to ensure efficient chip removal and prevent chip entanglement or damage to the workpiece or tools.

Machine Monitoring: Regularly monitor the machining process and machine performance. Keep an eye on cutting forces, tool wear, and any signs of issues such as vibration or chatter. Address any abnormalities promptly to avoid tool breakage or poor surface finish.

Coolant and Lubrication: Use coolant and lubrication systems effectively to control heat, reduce friction, and extend tool life. Proper coolant selection, flow rate, and application help maintain cutting performance and improve surface finish.

Quality Control: Implement thorough quality control measures to verify the dimensional accuracy and surface finish of the machined parts. Use precision measuring instruments and inspection techniques to ensure the parts meet the required specifications.

Machine Maintenance: Regularly maintain and calibrate the Swiss CNC lathe to ensure optimal performance. Keep the machine clean, lubricated, and properly aligned. Follow manufacturer guidelines for routine maintenance and address any issues promptly to prevent downtime and ensure consistent machining results.

Operator Training and Skill Development: Invest in operator training to ensure a thorough understanding of the Swiss CNC lathe's capabilities, programming techniques, and machining strategies. Continuously develop the skills of the operators to optimize machine utilization and maximize productivity.

By adhering to these considerations and applying effective techniques, you can maximize the capabilities of Swiss CNC lathes, achieve high-quality results, and improve overall machining efficiency.

Citizen Swiss CNC machining is a high-precision and versatile manufacturing process that offers many advantages for producing small, complex and high-precision parts. The ability of Swiss CNC machines to perform multiple operations in one setup simplifies the production process, increases efficiency and provides consistent and accurate results.

At VMT, we specialize in Swiss CNC machining, utilizing state-of-the-art equipment and skilled operators to deliver the highest quality precision parts. Whether you require small or high-volume production, our expertise and commitment to excellence ensure that your project is handled with the utmost care and precision.

Contact us today to discuss your specific machining needs and experience the precision and quality that Swiss CNC machining can provide.