15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

118 |

Published by VMT at Apr 17 2024

118 |

Published by VMT at Apr 17 2024

In the field of precision parts CNC machining, stress relief of materials is a crucial step. By alleviating stress, not only can the quality and performance of the parts be enhanced, but their lifespan can also be prolonged. This article delves into the benefits of material stress relief in precision parts CNC machining and elucidates its significance in practical applications.

Enhancement of Part Precision and Stability:

During precision parts CNC machining, residual stresses often develop within the material. These stresses can lead to deformation or dimensional changes in the parts during subsequent use, thereby affecting their precision and stability. Stress relief helps eliminate these adverse effects, ensuring that the parts exhibit higher dimensional accuracy and shape stability, particularly crucial for parts requiring tight tolerances, such as critical components in aerospace and medical devices.

Improvement of Mechanical Properties:

Stress relief also improves the mechanical properties of parts. Residual stresses can reduce the material's strength and toughness, increasing the brittleness of the parts. By removing stress, the material's original properties can be restored, enhancing the parts' tensile, compressive, and fatigue resistance. This is significant for parts subjected to high loads or frequent movements, such as components in automotive engines or machine tool spindles.

Enhancement of Corrosion Resistance and Wear Resistance:

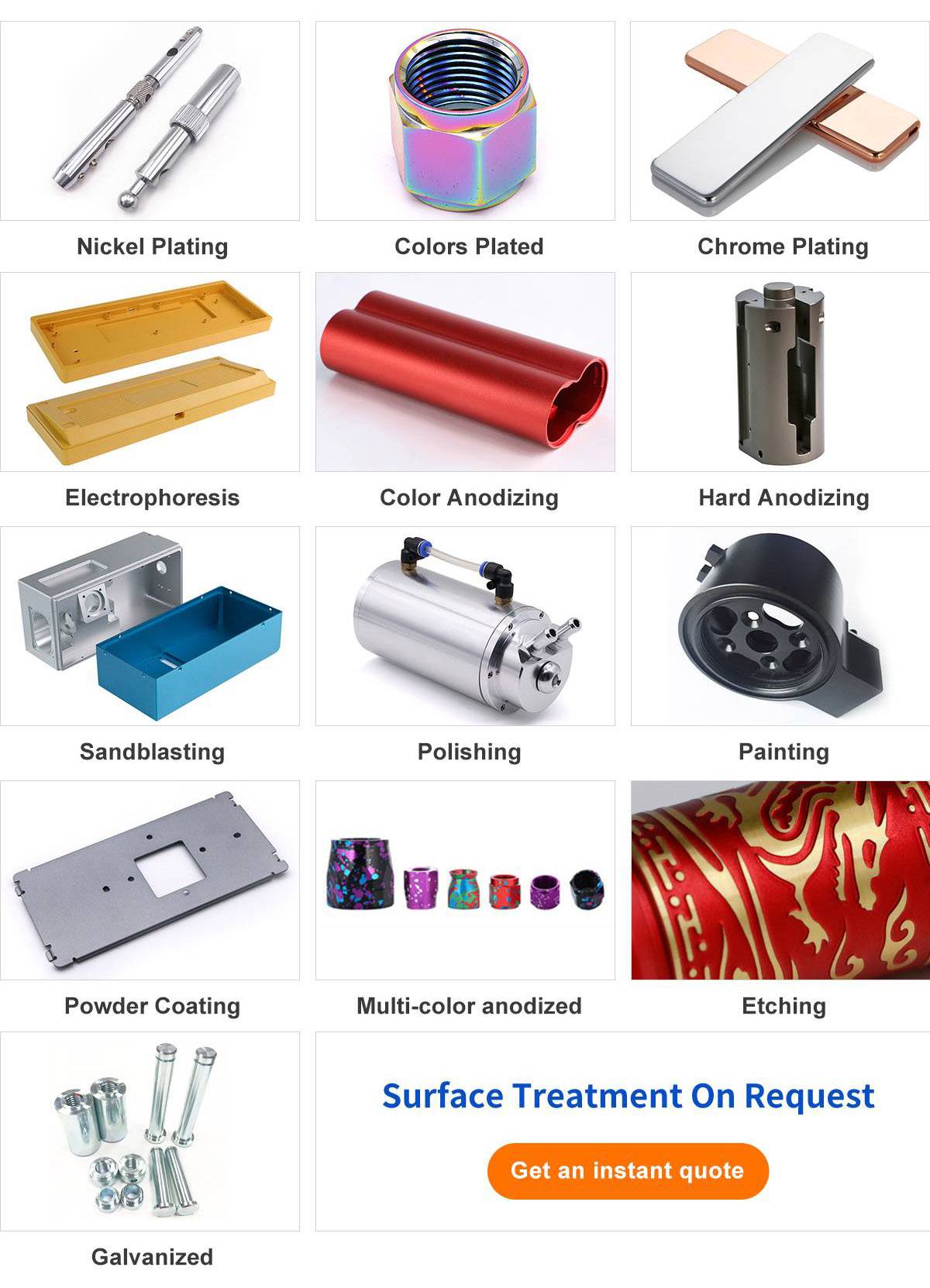

Residual stresses may lead to surface microcracks or defects in parts, reducing their corrosion resistance and wear resistance. Stress relief eliminates these surface defects, improving the surface quality of the parts. Additionally, employing appropriate surface treatment techniques, such as polishing or coating, further enhances the corrosion resistance and wear resistance of the parts, extending their service life.

Reduction of Production Costs and Increase in Production Efficiency:

Removing stress during CNC machining helps reduce subsequent machining operations and corrective work, thereby lowering production costs. Furthermore, optimizing CNC machining parameters and process flows can achieve more efficient material removal and stress relief, enhancing production efficiency. This translates to higher economic benefits and competitiveness for CNC machining factories.

Enhancement of Overall Product Quality and Reliability:

As integral components of complex products, the quality and performance of precision parts directly impact the overall product's performance and reliability. By removing stress during CNC machining, product quality can be improved from the source, reducing the risk of failures or malfunctions caused by stress. This is crucial for enhancing the overall quality and reliability of products, thereby enhancing their market competitiveness.

Advancement and Development of CNC Machining Technology:

With the continuous upgrading and development of the manufacturing industry, the requirements for the quality and performance of precision parts are increasing. CNC machining, as one of the core technologies of modern manufacturing, directly affects product quality and production efficiency. Stress relief during CNC machining is one of the essential means to improve machining accuracy and efficiency. Therefore, in-depth research on the benefits of stress relief in material removal can promote the advancement and development of CNC machining technology, providing strong support for the transformation and upgrading of the manufacturing industry.

In conclusion, material stress relief in precision parts CNC machining offers numerous benefits. It not only enhances part precision and stability, improves mechanical properties, and increases corrosion and wear resistance but also reduces production costs and enhances production efficiency. Therefore, CNC machining factories should prioritize the stress relief process, optimize machining parameters and process flows, and achieve more efficient and precise stress relief to lay a solid foundation for improving product quality and performance.

However, it's essential to recognize that material stress relief is not a one-time process; it requires comprehensive consideration of factors such as material properties, machining methods, and process parameters. Furthermore, with the emergence of new materials and technologies, effectively removing stress and improving machining quality will continue to be a topic of ongoing research and attention in the CNC machining field. Therefore, CNC machining factories should continually strengthen technological research and innovation to adapt to evolving market demands and technological challenges.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!