15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

147 |

Published by VMT at Apr 18 2024

147 |

Published by VMT at Apr 18 2024

In the field of precision parts CNC machining, preventing collisions and scratches during part processing has always been a key issue that CNC machining factories need to focus on and address. Collisions and scratches not only affect the appearance quality of parts but may also damage their performance and accuracy, leading to product defects or even scrap. Therefore, CNC machining factories need to take a series of measures to prevent collisions and scratches from occurring.

Optimize Part Handling and Clamping Methods

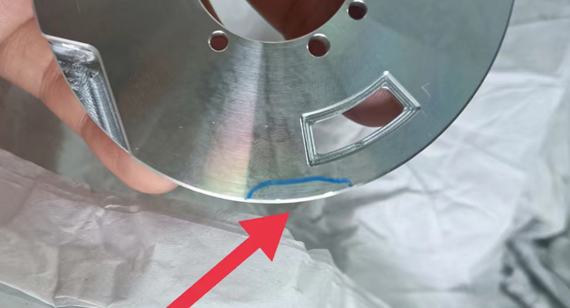

In CNC machining processes, the handling and clamping methods of parts are crucial for preventing collisions and scratches. Firstly, it is essential to ensure that parts do not come into direct contact with hard objects during pre-processing to avoid scratches. For parts with special surface protection requirements, such as plated layers or aluminum surfaces, appropriate protective films should be applied, ensuring the film is smooth without air bubbles.

Secondly, during part clamping, suitable fixtures should be chosen, and their cleanliness and integrity ensured. The clamping force of fixtures should be moderate to avoid over-tightening, which can cause part deformation or clamping injuries, while also ensuring the stability of parts during processing. Moreover, different clamping methods and forces should be selected based on the physical properties of parts with different materials.

Fine-tune Cutting Parameters and Tool Selection

Cutting parameters and tool selection are crucial factors affecting the quality of part machining. The settings of cutting speed, feed rate, and cutting depth should be adjusted reasonably according to the material, shape, and machining requirements of parts. Excessively high cutting speed and feed rate may increase the impact force between the tool and the part, thereby increasing the risk of collisions and scratches. Therefore, CNC machining factories should find the optimal combination of cutting parameters through experimentation and optimization.

Additionally, tool selection is also crucial. The appropriate tool material and type should be chosen based on the part material and machining requirements. Tools should maintain good sharpness, and heavily worn tools should be regularly inspected and replaced. Furthermore, improving tool wear resistance and cutting performance through optimizing tool geometry parameters and coatings can further reduce the occurrence of collisions and scratches.

Enhance Machine Tool Accuracy and Stability

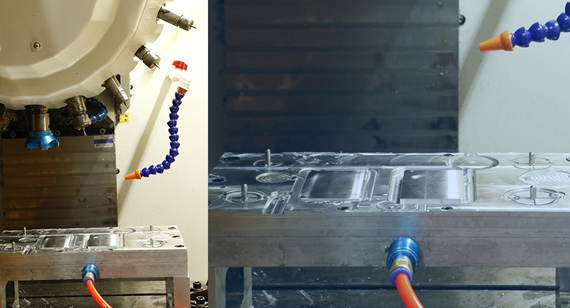

The accuracy and stability of machine tools have a decisive impact on the quality of part machining. CNC machining factories should regularly maintain and service machine tools to ensure they are in optimal working condition. This includes cleaning machine tool surfaces, inspecting lubrication systems and cooling systems, and adjusting machine tool accuracy. Moreover, attention should be paid to machine tool vibrations and noise issues, and corresponding measures taken to reduce their impact on machining quality.

Furthermore, for the machining of high-precision parts, CNC machining factories can consider using advanced machine tool equipment and technologies, such as high-precision CNC machine tools and five-axis simultaneous machining. These equipment and technologies can improve machining accuracy and stability, thus more effectively preventing collisions and scratches from occurring.

Strengthen Standard Operating Procedures and Personnel Training

Standard operating procedures are essential guarantees for preventing collisions and scratches. CNC machining factories should establish detailed operating procedures, clarifying requirements and precautions during the machining process. Operators should strictly follow these procedures to avoid collisions and scratches caused by improper operations. Additionally, factories should enhance training and assessment for operators to improve their skills and safety awareness.

Training should cover but not be limited to machine tool operation, tool use, and cutting parameter adjustment. Through training, operators can better master machining techniques and methods, improving machining quality and efficiency. Furthermore, factories should regularly organize skill competitions and safety knowledge contests to stimulate operators' enthusiasm and creativity.

Implement Comprehensive Quality Management

Comprehensive quality management is one of the key measures for preventing collisions and scratches. CNC machining factories should establish a sound quality management system, including raw material procurement, machining process formulation, process monitoring, and finished product inspection. In the raw material procurement stage, the quality and performance of raw materials should meet requirements. In the machining process formulation stage, reasonable machining processes should be formulated based on part characteristics and machining requirements. During the process monitoring stage, monitoring and adjustment of cutting parameters, tool conditions, and machine tool accuracy should be strengthened. In the finished product inspection stage, inspections should be conducted strictly according to standards to ensure product qualification.

Additionally, CNC machining factories should strengthen communication and cooperation with other departments to promote the comprehensive implementation of quality management work. Through comprehensive quality management, comprehensive control and optimization of the machining process can be achieved, thereby reducing the occurrence of collisions and scratches, improving product quality, and enhancing customer satisfaction.

Conclusion and Prospects

In summary, preventing collisions and scratches during part processing in CNC machining factories requires multi-faceted approaches. Through the comprehensive application of measures such as optimizing part handling and clamping methods, fine-tuning cutting parameters and tool selection, enhancing machine tool accuracy and stability, strengthening standard operating procedures and personnel training, and implementing comprehensive quality management, the occurrence of collisions and scratches can be effectively reduced, and part machining quality and efficiency can be improved.

In the future, with the continuous development and innovation of CNC machining technology, CNC machining factories will face more new challenges and opportunities. Therefore, CNC machining factories need to continuously monitor the development trends of new technologies and processes, continuously introduce and apply advanced technologies and equipment, and improve machining accuracy and efficiency. Additionally, they should strengthen cooperation and communication with other fields to jointly promote the progress and development of CNC machining technology.

Through the discussion and analysis in this article, it is believed that readers have gained a deeper understanding of how CNC machining factories can prevent collisions and scratches during part processing. It is hoped that these measures and suggestions can provide useful references and guidance for the practical work of CNC machining factories.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!