15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

223 |

Published by VMT at Jan 19 2024

223 |

Published by VMT at Jan 19 2024

Introduction:

In the manufacturing industry, quality inspection is a crucial step in ensuring products meet specified requirements. For customized aluminum CNC machined parts, given their unique material properties and machining processes, quality inspection becomes especially vital. This article explores the inspection process for customized aluminum CNC machined parts to ensure that the product quality meets the required standards.

1. Significance of Quality Inspection:

Quality inspection is a critical step in ensuring the quality of customized aluminum CNC machined parts. Effective quality inspection allows for the timely detection and correction of issues in the production process, preventing the generation of non-conforming products. This, in turn, enhances product quality and reduces production costs. Quality inspection also serves as a bridge for communication between businesses and customers, ensuring customer needs are met.

2. Inspection Content and Methods:

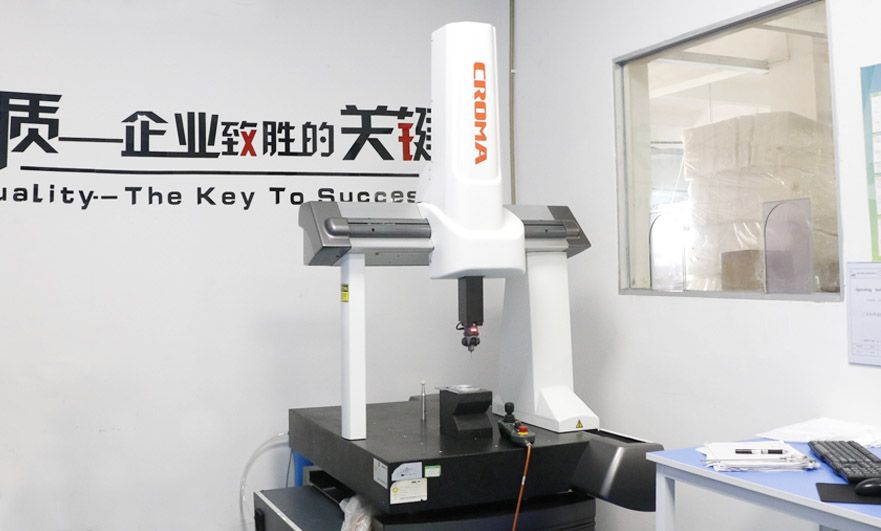

Dimensional Inspection: Utilize measurement tools to measure dimensions such as length, width, height, and hole diameters of aluminum CNC machined parts. Critical dimensions should undergo multiple measurements and comparisons to ensure compliance with design requirements.

Surface Quality Inspection: Inspect surface roughness, scratches, and any defects on the surface of CNC machined parts. Visual inspection, tactile inspection, or the use of surface roughness measurement devices can be employed for this purpose.

Structural Integrity Inspection: Use methods like tapping, vibration, or non-destructive testing to check for internal defects such as cracks or voids in aluminum CNC machined parts.

Material Composition Testing: Perform chemical analysis or spectroscopy to examine the material composition of aluminum CNC machined parts, ensuring it meets specified requirements.

Mechanical Performance Testing: Conduct mechanical tests such as tension, compression, and bending on aluminum CNC machined parts to evaluate their mechanical performance against design requirements.

Heat Treatment and Coating Inspection: Verify whether CNC machined parts have undergone the correct heat treatment and coating processes. Assess coating adhesion and thickness against industry standards.

3. Quality Inspection Process and Implementation:

Establish Inspection Plans: Develop detailed inspection plans based on the characteristics and requirements of customized aluminum CNC machined parts. Clearly define inspection content, methods, frequency, and acceptance criteria.

Training of Inspection Personnel: Ensure that inspection personnel possess the necessary skills and knowledge. Regular training and assessments should be conducted on the use of inspection tools and equipment.

Execute Inspections: Carry out inspections of customized aluminum CNC machined parts according to the established plans. Record detailed inspection data and results. Non-conforming products should be identified, isolated, and addressed.

Data Analysis and Continuous Improvement: Analyze inspection data to identify issues and improvement opportunities in the production process. Develop improvement measures and continually optimize production processes and inspection procedures.

Customer Communication and Feedback: Communicate promptly with customers regarding product quality. Actively analyze customer feedback, address identified issues, and incorporate customer needs and opinions into the quality inspection and product improvement processes.

4. Quality Assurance Measures:

Strict Raw Material Control: Ensure the selection of high-quality raw materials, verifying that the aluminum material meets specified composition, structure, and performance requirements. Regularly assess and audit suppliers to ensure stable raw material quality.

Enhanced Production Process Control: Establish strict production processes and operating procedures to control key process parameters effectively. Intensify monitoring and recording of production processes to promptly identify and correct anomalies.

Continuous Improvement and Innovation: Encourage employees to propose improvement ideas and suggestions continually. Stay informed about industry trends and developments in new technologies, applying innovations to production practices to enhance product quality and competitiveness.

Establish a Robust Quality Management System: Build a comprehensive quality management system to ensure the effective implementation of quality inspection work. Conduct regular internal audits and management reviews to identify system issues and implement improvements.

Strengthen Collaboration and Communication with Customers: Foster good relationships with customers, understanding their needs and feedback. Through effective communication, jointly address quality issues, enhance customer satisfaction, and promote the long-term development of the enterprise.

Conclusion:

Quality inspection and assurance for customized aluminum CNC machined parts are crucial for product quality and the reputation of a business. By creating detailed inspection plans, conducting effective quality inspections, continuous data analysis, and improvement, as well as reinforcing production process control, businesses can ensure that their products meet required standards and gain customer trust. Additionally, strong collaboration and communication with customers, timely issue resolution, and feedback incorporation contribute to increased customer satisfaction and support the long-term growth of the enterprise.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!