15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

340 |

Published by VMT at Jan 11 2024

340 |

Published by VMT at Jan 11 2024

Introduction:

Aluminum casings, known for their lightweight, aesthetic appeal, and durability, find widespread applications across various industries. However, during the CNC machining process of aluminum casings, issues related to poor surface finish may arise. This article delves into the reasons behind the subpar surface finish in CNC machining of aluminum casings and explores strategies to address this issue. Additionally, it examines whether changing the surface treatment facility can be a viable solution.

In cases where the surface finish of aluminum casings is subpar in CNC machining, the issue may not solely stem from surface treatment. CNC machining involves multiple facets, including material quality, machining parameters, tool selection, equipment precision, among others, all of which can influence the final surface quality. Therefore, changing the surface treatment facility may not completely resolve the issue.

Identifying Specific Causes of Poor Surface Finish:

Firstly, it's crucial to pinpoint the specific reasons for the unsatisfactory surface finish. It could be related to issues with the material itself, such as purity or internal structural concerns. Alternatively, improper machining parameter settings, like cutting speed and feed rate, or inappropriate tool selection and equipment precision, could be contributing factors.

Considering a Change in Surface Treatment Facility:

If it is determined that the problem lies in surface treatment, considering a change in the surface treatment facility is a viable option. However, when selecting a new facility, certain considerations are essential:

Understanding Process and Equipment:

Gain insights into the new facility's process flow and equipment conditions. Variations in processes and equipment can impact the final surface quality, necessitating a comprehensive evaluation before making a choice.

Reviewing Processing Examples:

Request processing examples from the new facility to assess and compare their capabilities. These examples should cover a range of aluminum materials with different thicknesses for a holistic evaluation.

Conducting Trial Machining:

Prior to finalizing the selection, conduct trial machining to assess the facility's machining effectiveness. Control factors such as machining parameters and material to better evaluate the machining results.

Conclusion:

In conclusion, poor surface finish in CNC machining of aluminum casings may not be solely attributed to surface treatment issues. It is essential to identify the specific root causes before implementing a solution. If the problem is related to surface treatment, changing the facility is a valid consideration. However, careful evaluation of the new facility's process, equipment, processing examples, and trial machining is necessary for a successful transition.

I. Causes of Poor Surface Finish in CNC Machining of Aluminum Casings:

Several common reasons may contribute to the poor surface finish in CNC machining of aluminum casings:

Improper CNC Machining Parameters:

Incorrect settings such as cutting speed, feed rate, and cutting depth during CNC machining of aluminum casings can lead to a decline in surface quality.

Inappropriate Tool Selection:

The choice of tools plays a significant role in surface quality during CNC machining of aluminum casings. Inadequate sharpness or incorrect cutting angles can result in increased surface roughness.

Subpar Material Quality:

If the aluminum material used for CNC machining exhibits quality issues, such as uneven composition or internal cracks, it can negatively impact the surface quality of the machined casings.

Equipment Aging or Poor Maintenance:

Over time, CNC machining equipment may experience wear and aging. Lack of timely maintenance can directly affect surface quality during the machining process.

II. Strategies for Improving Surface Finish in CNC Machining of Aluminum Casings:

To address the issue of poor surface finish in CNC machining of aluminum casings, a systematic approach is required:

Adjust CNC Machining Parameters:

Reevaluate and adjust CNC machining parameters, including cutting speed, feed rate, and cutting depth, based on the characteristics of aluminum material and specific machining requirements to enhance surface quality.

Choose appropriate tools tailored to the characteristics of aluminum material. Ensure tools maintain sharpness and correct cutting angles. Regularly inspect tools for wear and promptly replace heavily worn ones.

Control Material Quality:

Implement rigorous quality checks on the aluminum material used for CNC machining to ensure it meets specified quality standards. Pre-treat or select only qualified materials for processing.

Equipment Maintenance and Upkeep:

Conduct regular maintenance on CNC machining equipment to address wear and aging issues. Timely replacement or repair of worn components is crucial to maintaining the quality of machined surfaces.

Optimize Surface Treatment Processes:

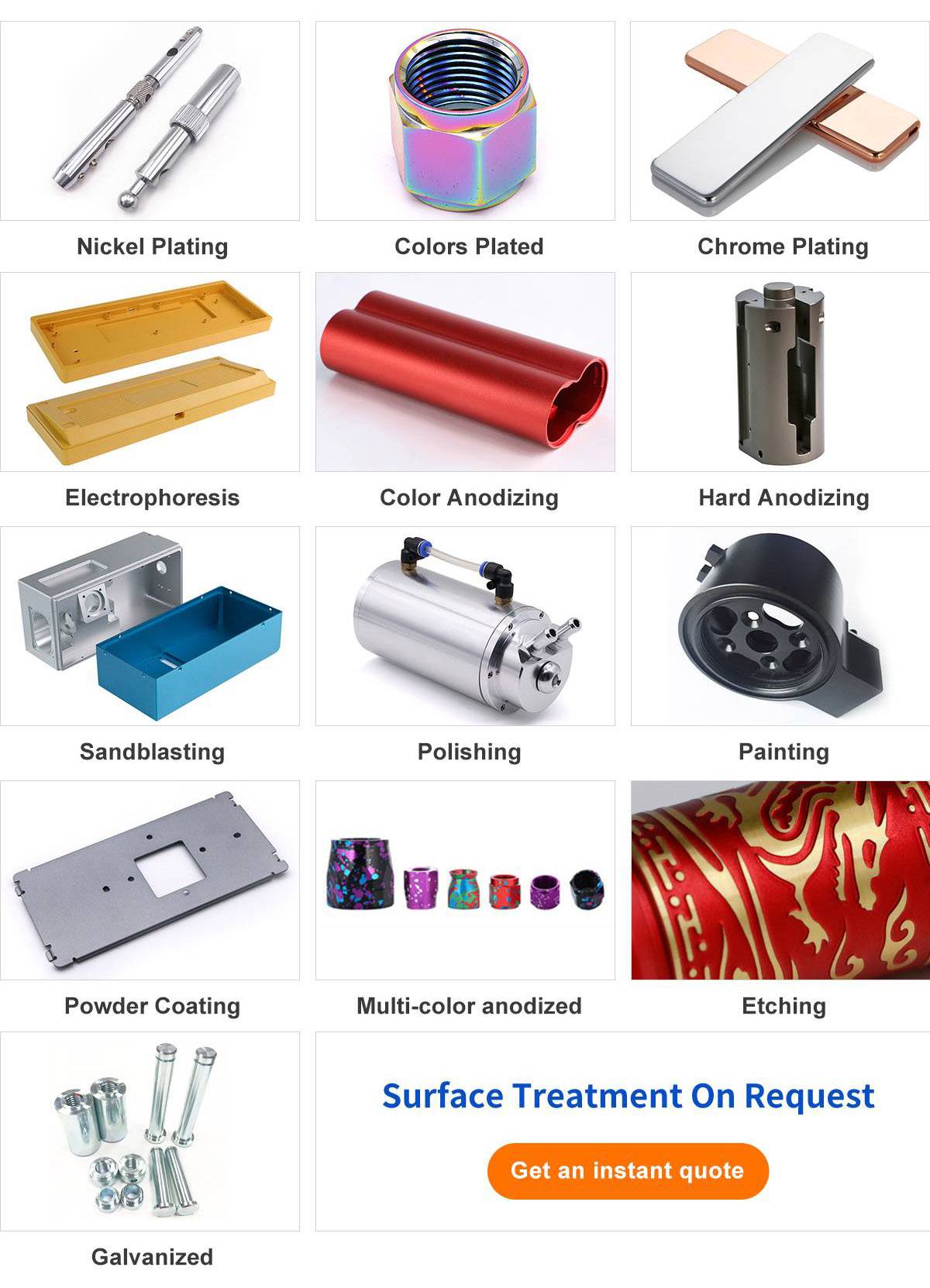

Depending on the specific requirements and applications of aluminum casings, optimize surface treatment processes such as painting or plating. Adjust process parameters to improve overall surface quality and aesthetics.

Training and Skill Enhancement:

Provide training to CNC machining operators to enhance their skills and understanding of the machining process for aluminum casings. Empower operators with knowledge on adjusting parameters and handling equipment for improved results.

Implement Quality Inspection Mechanisms:

Establish a comprehensive quality inspection mechanism to examine the surface quality of CNC machined aluminum casings. Identify and analyze instances of poor surface finish, and implement corrective measures to prevent reoccurrence.

Seek External Support:

If internal efforts do not resolve the issue, consider seeking external support from specialized research institutions, universities, or surface treatment facilities. Collaborate to access advanced technological solutions and expertise.

III. Can Changing the Surface Treatment Facility Solve the Problem?

Changing the surface treatment facility is not a direct solution to addressing poor surface finish in CNC machining of aluminum casings. Surface treatment facilities primarily focus on providing post-machining treatments such as painting or plating, rather than influencing the fundamental machining process.

However, if thorough collaboration and communication occur between the CNC machining facility and the surface treatment facility, and the latter possesses advanced technology and relevant expertise, changing the surface treatment facility could be part of a comprehensive solution. Collaborative efforts may lead to improved overall quality, including surface finish, of the aluminum casings.

Conclusion:

Addressing the challenge of poor surface finish in CNC machining of aluminum casings requires a multifaceted approach. Companies should analyze the root causes, implement targeted strategies, and consider collaboration with external partners if needed. While changing the surface treatment facility is not a direct remedy, a collaborative approach can lead to comprehensive solutions, gradually improving the surface quality of CNC-machined aluminum casings, meeting customer requirements, and enhancing product competitiveness.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!