15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

148 |

Published by VMT at Jan 10 2024

148 |

Published by VMT at Jan 10 2024

Introduction

In today's highly competitive manufacturing environment, quality has become a crucial component of core competitive strength for businesses. For CNC machining factories, quality control in the production process is particularly vital. This article explores the role of quality control in custom CNC machining part production for CNC machining factories and outlines the process of quality control.

I. Role of Quality Control in the CNC Machining Factory

Production process quality control plays a vital role in the manufacturing industry, and its importance is reflected in the following aspects:

Enhancing Product Quality:

Rigorous quality control aims at ensuring the stability and reliability of product quality. By implementing strict quality control in the production process, potential quality issues can be promptly identified and resolved, minimizing the generation of non-conforming products. This contributes to an overall improvement in product quality, meeting the high-quality demands of customers.

Building Customer Trust:

High-quality products are key to gaining customer trust. Effective quality control allows CNC machining factories to ensure the stability and consistency of product quality, thereby earning the trust of customers. This trust not only aids in maintaining existing customer relationships but also attracts new customers, further expanding market share.

Increasing Production Efficiency:

Quality control in the production process not only focuses on product quality but also emphasizes enhancing production efficiency. By reducing faults and defects in the production process, quality control helps improve equipment utilization, reduce production costs, and shorten delivery cycles. This contributes to an overall enhancement of the CNC machining factory's production efficiency and profitability.

Risk Reduction:

Process control enables manufacturers to identify potential problems during the production process, take timely actions, and prevent unforeseen events. This, in turn, reduces risks faced by both the enterprise and its employees.

Improving Resource Utilization:

Through process control, precise insights into the utilization of resources at each stage can be gained. Optimization of inefficient or wasteful processes becomes possible, leading to increased resource utilization and reduced waste.

Enhancing Competitive Edge:

By accumulating experience through process control, businesses can elevate their manufacturing capabilities and technological prowess, thereby enhancing their competitive edge.

Promoting Sustainable Development:

Quality serves as a cornerstone for the sustainable development of a business. Effective quality control helps CNC machining factories maintain a competitive advantage in a fiercely competitive market, achieving sustainable development. By continually improving product quality and production efficiency, businesses can better meet customer demands, ensuring long-term stability and growth.

II. Process of Quality Control in Production

Establishing Quality Standards and Inspection Plans:

CNC machining factories need to define clear quality standards and inspection plans. These standards should be based on customer requirements, industry regulations, and the company's quality objectives to ensure that products meet market demands. Simultaneously, inspection plans should be developed, outlining inspection items, methods, frequencies, and acceptance criteria based on product characteristics and production processes.

Quality Control of Raw Materials:

The quality of raw materials directly impacts the final product's quality. Therefore, quality control of raw materials is a crucial aspect of quality control. CNC machining factories should ensure purchased raw materials meet quality requirements, assess and select suppliers, and strengthen pre-receipt inspection of raw materials. In case of non-conforming raw materials, timely actions should be taken, and the root causes traced to prevent similar issues in the future.

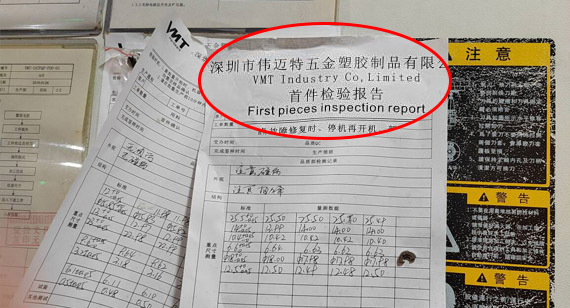

Production Process Monitoring and Inspection:

Comprehensive monitoring and inspection plans should be implemented during the production process. Using appropriate testing equipment and tools, real-time monitoring and sampling of critical processes should be conducted to ensure product quality aligns with expected standards. Additionally, attention should be given to equipment maintenance to ensure machines are in good condition, preventing quality fluctuations due to equipment malfunctions.

Finished Product Inspection and Traceability:

Final product inspection serves as the last line of defense for quality control. Before products leave the factory, a thorough inspection should be conducted to ensure they meet customer requirements and quality standards. For non-conforming products, isolation and traceability analysis should be carried out to identify causes and implement corrective measures promptly. Simultaneously, establishing a finished product traceability system enables quick identification of responsibilities and reasons in case of product issues.

Quality Improvement and Continuous Development:

Quality control is an ongoing improvement process. Through data analysis of the production process, summarizing quality incidents, and collecting customer feedback, potential quality issues and improvement areas can be identified. Based on this information, appropriate improvement measures should be formulated and implemented to enhance product quality and the stability of the production process. Encouraging employee participation in quality improvement activities contributes to heightened overall quality awareness and engagement.

Conclusion:

In conclusion, quality control in custom CNC machining part production holds significant importance for CNC machining factories. By implementing effective quality control processes, these factories can elevate product quality, build customer trust, enhance production efficiency, and promote sustainable development. To achieve these goals, factories should establish clear quality standards and inspection plans, rigorously control raw material quality, monitor and inspect the production process, conduct thorough finished product inspections and traceability, and continually pursue quality improvement and innovation. Only through these measures can businesses continuously enhance their core competitiveness and maintain a leading position in the fiercely competitive market.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!