15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

301 |

Published by VMT at Oct 27 2023

301 |

Published by VMT at Oct 27 2023

Aluminum CNC machining is a highly precise process that demands careful attention to every detail. While the final product should ideally be flawless, challenges can arise during the machining process, such as material damage and cracking. In this article, we will explore the causes of these issues and present effective strategies for preventing and resolving them.

Causes of Material Damage and Cracking in Aluminum CNC Machining

Before we explore solutions, it's crucial to comprehend the nature of the problem. Material damage and cracking in aluminum CNC machined parts can result from various factors, such as:

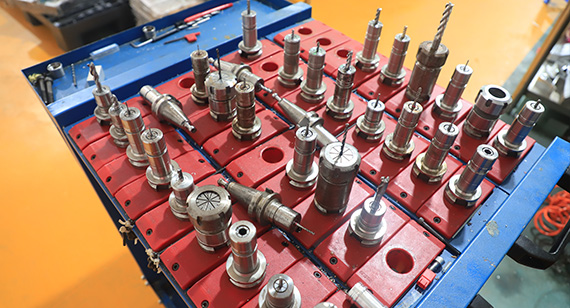

1. Tool Selection: Inadequate tool selection, including the wrong type or a dull tool, can cause excessive heat buildup during machining. This can lead to aluminum's thermal softening, which makes it susceptible to damage.

2. Incorrect Cutting Parameters: Using improper cutting speeds, feeds, or depth of cuts can generate excessive heat and friction, potentially causing material damage or cracks.

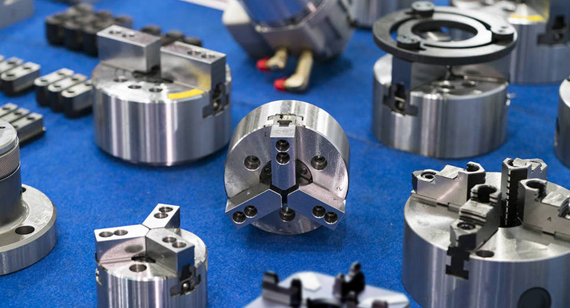

3. Workholding Issues: Inefficient or unstable workholding methods may cause vibrations or shifts during machining, leading to inconsistent cutting forces and, subsequently, damage to the material.

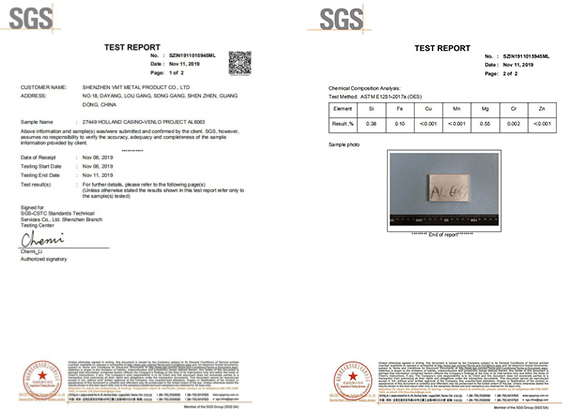

4. Material Quality: The quality of the aluminum stock itself is a significant factor. Inconsistent material composition or impurities can create weak points prone to damage.

Effective Solutions to Address Material Damage and Cracking

Tool Optimization: Begin by selecting the appropriate cutting tools designed for aluminum machining. These tools should have sharp edges and the right geometry to minimize heat generation. Regular tool maintenance and replacement are also essential.

Optimize Cutting Parameters: Accurate control of cutting speeds, feeds, and depths of cut is vital. Machining at lower speeds and utilizing proper coolant/lubrication can help manage heat and reduce the risk of material damage.

Workholding Precision: Ensure your workholding setups are rigid and secure. Vibration-damping fixtures and precision clamping mechanisms can mitigate unwanted movement and reduce the chance of damage.

Material Inspection: Prior to machining, thoroughly inspect the aluminum material for impurities, inclusions, or defects. High-quality aluminum stock reduces the risk of damage during machining.

Advanced Machining Techniques: Consider employing advanced machining techniques like high-speed machining (HSM) or trochoidal milling. These methods can significantly reduce heat generation and improve surface quality.

Coolant and Lubrication: The application of appropriate coolants or lubricants can have a profound impact on machining aluminum. These substances help dissipate heat and reduce friction.

Quality Control: Implement a rigorous quality control process during and after machining to identify any signs of material damage or cracking early. This allows for immediate corrective actions.

Heat Management: When dealing with thicker aluminum components, strategic toolpaths and machining strategies can be used to manage heat buildup.

Methods to Prevent Damage and Cracking of CNC Machining Materials

Achieving excellence in aluminum CNC machining starts with a comprehensive approach. Here's how to ensure the best possible results:

1. Rigorous Material Selection: Choosing the right grade of aluminum is crucial. Different alloys have varying properties, and selecting the one that suits your application can significantly reduce the risk of material damage.

2. Quality Control: Implement a stringent quality control process that includes both incoming material inspection and continuous monitoring during machining. This way, you can quickly detect any deviations from specifications.

3. Effective Toolpath Planning: Developing a well-thought-out toolpath minimizes unnecessary tool engagement and heat generation. This approach is especially critical when dealing with intricate components or deep cavities.

4. Heat Management: Utilize tools with optimized geometries designed to evacuate chips efficiently, reducing heat buildup. Controlling cutting speeds, feeds, and depths of cut is equally vital for managing heat.

5. Lubrication and Cooling: Employ appropriate coolants and lubricants to aid in heat dissipation. These fluids also act as a barrier, reducing friction and minimizing wear on the tool and workpiece.

6. Workholding Precision: Ensure your workholding solutions are designed to minimize vibration and securely hold the material. Consider advanced clamping methods for complex geometries.

7. Continuous Monitoring: Implement real-time monitoring systems that can detect unusual vibrations or forces during machining. This allows for quick intervention to prevent potential damage.

8. Post-Machining Inspection: After CNC machining is complete, conduct a final inspection to ensure the components meet your exacting standards. Any deviations should be addressed promptly.

9. Ongoing Training: Invest in the training and development of your CNC machining team. Knowledgeable operators are more likely to detect issues early and make informed adjustments.

10. Advanced Machining Techniques: Explore advanced techniques such as high-speed machining (HSM) and adaptive machining. These approaches can enhance efficiency and reduce the risk of damage.

Conclusion

When it comes to aluminum CNC machining, understanding the nuances of the material, using advanced tooling, and implementing meticulous processes are key to resolving material damage and cracks. Material damage and cracks can be prevented and resolved by following best practices in tool selection, cooling and machining parameters. With proper quality control and a willingness to make adjustments when problems arise, you can deliver the highest quality aluminum CNC machined parts.

In our next segment, we will delve into another critical aspect of CNC machining: maintaining surface finish quality. Stay tuned for more insights and strategies to excel in CNC machining projects.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!