15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

142 |

Published by VMT at Oct 06 2022

142 |

Published by VMT at Oct 06 2022

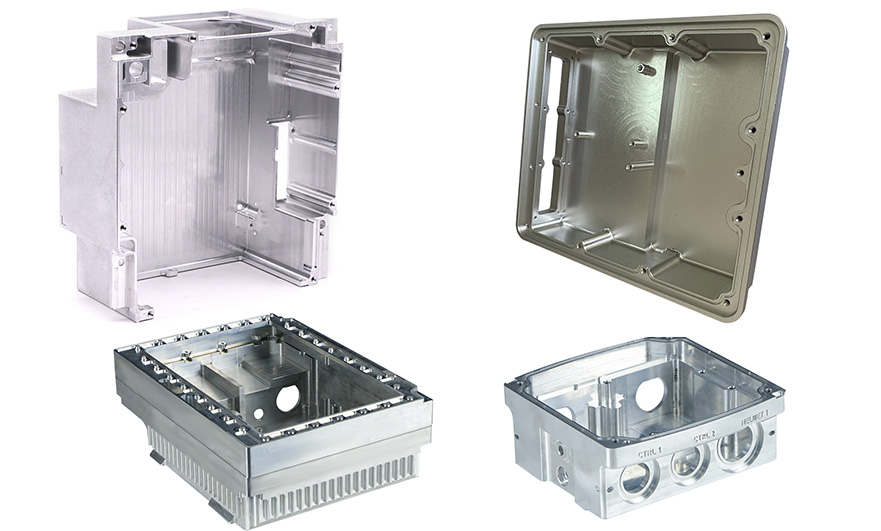

The main factors for the deformation of the communication cavity during the CNC machining process are the shape complexity, aspect ratio and wall thickness of the cavity; the rigidity and stability of the material. Therefore, it is important to reduce the influence of these factors on parts when designing, especially large parts need to be structurally reasonable. In addition, problems such as blank hardness and slagging should be strictly controlled to reduce deformation.

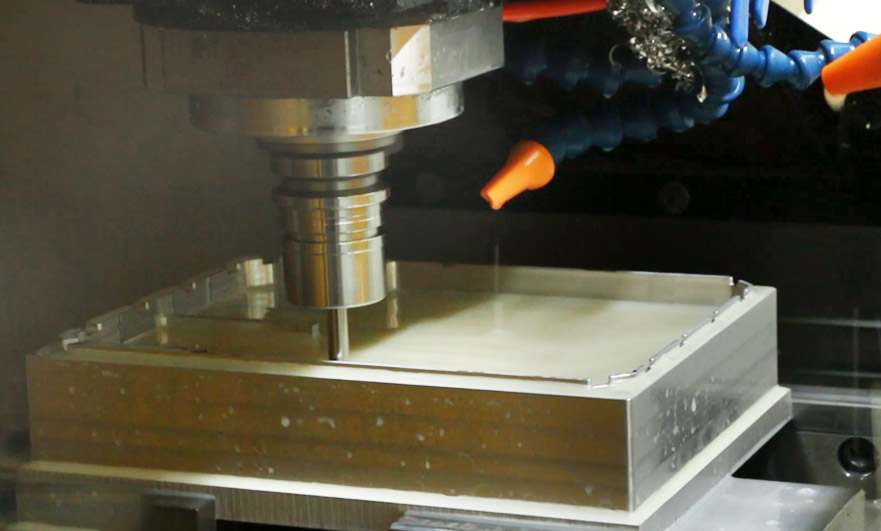

Workholding

The workpiece clamping is easy to cause the deformation of CNC machining parts. In order to avoid this deformation, it is necessary to select the correct clamping point and select the appropriate clamping force according to the position of the clamping point. Therefore, try to keep the clamping point and the supporting point consistent, let the clamping force act on the supporting effect, and the clamping point can be closer to the CNC machined surface, so that it is not easy to cause deformation due to clamping.

For example, when a CNC machining center processes the filter cavity, certain auxiliary devices are required to facilitate CNC machining of the filter cavity. Clamping and rotating, because the processing of the filter cavity will be limited, so that the auxiliary device cannot be used flexibly, reducing the CNC processing efficiency and processing quality.

When the workpiece has several directions of clamping force, consider the order of clamping force. In addition to completing the above steps, it is necessary to increase the contact area between the CNC machined part and the fixture or use the axial clamping force to increase the rigidity of the part. This is the most effective way to solve the problem of clamping deformation.

CNC Machining Process

During the cutting process, CNC machined parts are affected by cutting forces. This is an elastic deformation in the direction of force. This deformation can be improved on the tool. When finishing, the tool is required to be sharp, which can reduce the frictional resistance between the tool and the workpiece, and can also improve the heat dissipation capacity of the cutting workpiece and reduce the residual internal stress on the CNC machined parts.

Stress Deformation After CNC Machining

The CNC-machined part itself has a relatively balanced internal stress state. Although the shape of the part is relatively stable at this time, when some material is removed and heat treated, the internal stress will change, and the workpiece needs to regain the force balance. This can be improved by heat treatment to maintain the stability of the internal structure of the workpiece after thermal straightening.

The above is just a summary of the VMT CNC machining factory. If you want to know more about CNC machining, you can contact us: inquiry@vimetal.com.cn to negotiate with us.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!