15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

242 |

Published by VMT at Jan 21 2022

242 |

Published by VMT at Jan 21 2022

Mild steel is a material with low hardness and high viscosity, and its cutting performance is poor. In order to make the surface roughness of CNC machined holes reach Ra=1.6m after finishing, most of them use high-speed steel reamers and low-speed reamers to complete the hole processing through three processes of drilling, expanding and expanding.

Although this process can meet the precision requirements of CNC machining, it has low production efficiency and short tool life. During the reaming process, if there is a small amount of debris on the front surface of the reamer edge, the hole wall will be pulled out and scratched, thus affecting the surface quality of the CNC machined part hole. In order to solve the above-mentioned shortcomings caused by the ordinary process, the high-speed hole expansion test was carried out on the hole machined by the cemented carbide reamer, and satisfactory results were obtained.

Reaming is a cutting process that uses a special tool called a reamer to enlarge an existing hole to a precise diameter while creating a smooth finish on the hole walls. Reamers are usually performed on milling machines, lathes or drilling machines. Therefore, the hinge is a finishing operation. Another method, like drilling, has to make the hole thicker before it can be reamed.

There are other ways to create precise diameters and a high-quality finish on the wall, but reaming is often the best option and low cost.

If you need a tighter tolerance than +/- 0.002" on the hole diameter, a reamer is probably the best option.

The surface finish of the reamer depends on the CNC machined part material. Cast iron ranges from 50 to 80 rms and steel from 30 to 60 rms. PCD reamers are capable of 8 RMS finishing in aluminum.

How can I dig a hole?

Proper reaming depends first and foremost on the preparation of the hole. The reamer can only remove a small amount of material from the hole, and it tends to travel along the hole. If it has front-cut capability, it can only slightly improve the straightness of a hole. A 1/4" reamer improves the straightness of the hole by 0.005", but no further.

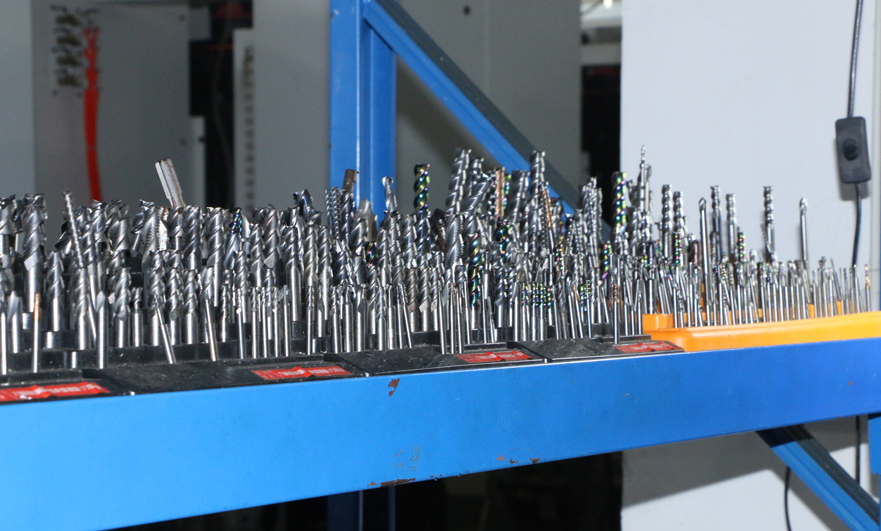

Carbide Reamers

The geometric angle of the tool. High-speed steel reamer and cemented carbide reamer (see attached photo) have different cutting principles. Low surface roughness values, so the geometric angle of the tool is different from that of ordinary high-speed steel reamers.

According to the cutting principle, when cutting a soft low carbon steel reamer, the cutting edge must be sharp, so a positive rake angle and a large relief angle are selected. This can reduce the cutting resistance of the tool, but in order to improve the strength of the tool tip, it is not easy to break the blade, set the tool rake angle γ0=3°, blade angle λs=20°, back angle α0=20°, blade width BA1= 0.5~0.6mm (reamer φ2 0~2 5 mm), can obtain better cutting effect. At this time, the surface roughness of the hinge hole is Ra=3.2~1.6μm, and the tool life is also high.

Determination of tool material for CNC machining parts

The material of the blade directly affects the service life of the tool. The results are also different after making the reamer with YT 15, YA6, YW1, YT5 and YW2 blades of different materials. The surface roughness of the reamer made of YT 15 material is low, but the cutting edge is easy to collapse during the cutting process. The surface roughness of the reamer made of YT5 and YA6 materials is Ra=3.2~1.6m after the reamer, but compared with other blade materials, the tool wear rate is fast and the service life is low.

For the reamer made of YW1 material, the surface roughness of the reamer after the reamer is Ra=1.6 μm, but due to the low bending strength of the blade, the blade edge is prone to collapse. Compared with the reamers of different grades mentioned above, the reamer processed by YW2 has a lower surface roughness value (Ra=1.6m) and higher tool life in the processing of low carbon steel.

Whether the CNC machining process is reasonable and directly affects the cutting effect?

In the CNC machining of low carbon steel, the original three processes of drilling, expanding and expanding are transformed into two processes of drilling and expanding. Since the feature of the cemented carbide hinge is extrusion, the margin before the hinge leaves the hinge is very important. The margin is too small to play the role of the hinge. Insufficient margin will cause the hinge to fail, which may cause the hole to be too large. , There are drilling marks on the surface of the hole; too large allowance will increase the cutting resistance, deform the tool bar, and at the same time, the tool life will be significantly reduced, and even a large number of chips and drawn hole surfaces will be generated. Taking φ20~φ25 mm reamer as an example, the reamer allowance is generally 0.20~0.25mm.

The choice of a reasonable cutting allowance has a great influence on the hole quality of the hinged mild steel material. Low-speed cutting (VC<5m/min) with carbide reamer can obtain lower surface roughness, but the cutting efficiency is too low. Medium-speed cutting is prone to chip nodules, which affect the surface quality of the hole. High-speed cutting is an ideal machining method, which not only greatly improves the productivity of CNC machined parts, but also achieves good CNC machining quality. Tool life can be improved if the cutting fluid is suitable (preferably extreme pressure cutting fluid).

The test results show that the cutting amount of the articulated low carbon steel material is: cutting speed VC=50~60m/min, feed F=0.5~0.6mm/r.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!