15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

193 |

Published by VMT at Nov 26 2021

193 |

Published by VMT at Nov 26 2021

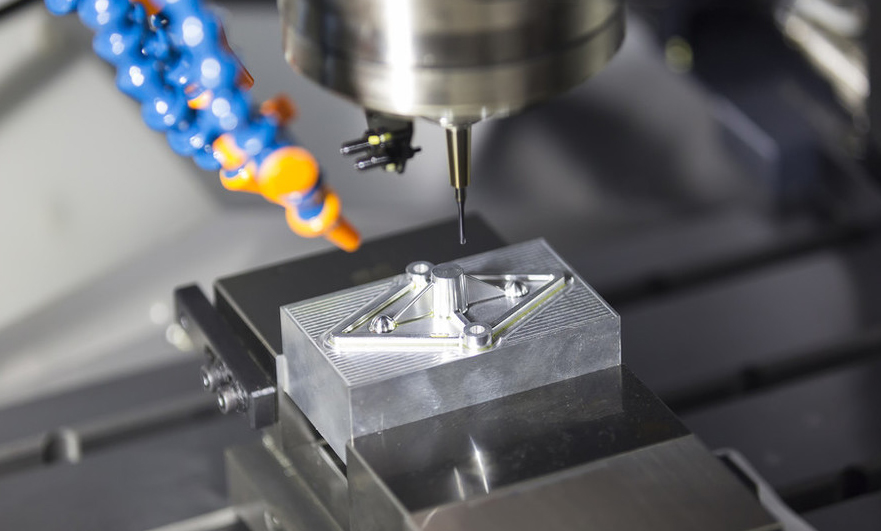

As the cornerstone of production or engineering testing, prototypes machining are very important in the design, development and improvement process. For individual companies and research institutions, prototyping machining is fast and economical, and they never need to invest in hard tools and equipment. Most customers need to produce a physical part in a short time to verify their design, and then seize the part sales opportunity.

Prototyping machining is one of the ideal methods, the process of CNC machining manufacturing in the consumer industry. It is also realizing an idea while helping development. As an individual, you should choose the CNC machining service project that suits you. Prototyping machining services benefit designers because it inspires people and enables your ideas to bring some good things. It also provides space for more research and advancement. The production process of CNC machining service is as follows.

1. Mold Making

The prototype machioning process requires molds, and there are facilities to use them in the enterprise resource planning. The molds manufactured include metal injection molds and plastic injection molds. All of these are locally produced, so the cost is low. To avoid the split of the project. Moulds can also be shipped directly to individuals, with fast turnaround time.

2. Rapid Prototyping Machining

Rapid Prototyping machining is the most cost-effective way to create molds for rapid Prototyping machining in a short period of time. VMT uses comprehensive expertise to produce high-quality rapid tooling solutions. The company will communicate with each customer one-on-one to ensure the implementation of the best solution.

The surface of the final CNC machined part is changed to the customer according to the customer's needs. VMT CNC machining company has set up a professional surface treatment team to ensure the production of high-quality CNC machining parts.

VMT has excellent vacuum casting + CNC machining capabilities. We will manufacture with competitive CNC machining cost and turnaround fast. Suitable for high-quality prototype CNC machining parts.

The goal of this service is to make flexible and even rigid CNC machined parts an ideal use for high-quality prototypes machining. Ideally, your prototype development process will only take a month or two at most, but this process may take longer, depending on where you are in the design process. The best way to ensure that your ideas pass through the Prototyping machining phase as quickly and efficiently as possible is to prepare an initial prototype or drawing for the prototype engineer. This gives the engineer a clear idea of ??what you want your product to look like and how you want it to work.

However, it is not always possible to enter the prototype production process with a self-made prototype. You may lack time, supplies, and/or experience. The best prototyping machining companies will not do this. They will be willing to go back to the very beginning and work closely with you on the design. Skilled engineers can even smear napkins, or you still have only one idea in your mind-they are open-minded.

If you don't know all the details of your project, that's okay. However, the answers to these three questions are extremely important. Without them, you will waste time questioning your production decisions, rethinking your design, and falling into a dead end-this is where you could have spent time actively making a prototype or preparing your production line.

However, even if you don't have all these answers, an experienced CNC machining manufacturer can still support you. In fact, the sooner you reach your manufacturer, the smoother the process will be. It is best to resolve these details as soon as possible under the advice of an experienced manufacturer, rather than to find these answers alone without fully understanding the process. A good manufacturer will ensure that your project runs as smoothly as possible, even if you make mistakes or encounter obstacles in the process. With their help, even complex processes like Prototyping machining and production have become easier to navigate.

5. Extrusion + CNC Machining Service

When you need dosing + CNC machining, VMT can provide you with the best CNC machining parts service. In terms of quality and delivery, each customer's project is successfully completed. DFM analysis selects suitable CNC machining materials and solutions for customers. The CNC machining parts are all custom-made and manufactured according to the customer's drawings.

Services under CNC machining include CNC milling and CNC turning. Through a professional team and 11 years of experience in CNC machining parts prototype manufacturing, VMT pushes customer parts into the market at the fastest speed, bringing value to customers.

7. Metal Machining and Manufacturing Services

Metal machining and manufacturing services involve metal bending, cutting, punching, stamping, welding, assembly and packaging. One-stop payment for CNC machining. According to the use performance of CNC machined parts, more than 40 metal materials are provided. The machining speed is fast and the production efficiency is high.

In Conclusion

CNC machining can process plastic and metal parts. Provide rapid Prototyping machining to make customers' ideas quickly become reality, reduce time costs, and speed up the development of CNC machining parts projects.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!