15 years one-stop China custom CNC machining parts factory

419 |

Published by VMT at Jan 28 2022

419 |

Published by VMT at Jan 28 2022

Understanding Magnesium Alloys

Magnesium alloys are metal alloys primarily composed of magnesium, along with various other elements such as aluminum, zinc, manganese, and rare earth metals. These alloys exhibit remarkable properties, including lightweightness, high strength-to-weight ratio, and excellent thermal conductivity. Magnesium alloys are commonly used in industries like aerospace, automotive, electronics, and medical.

As the lightest engineering metal material, magnesium alloy is known as "21st century green engineering material". It has the advantages of high strength, good impact resistance, good heat dissipation, good dimensional stability, and large elastic modulus, and its ability to withstand impact loads is stronger than that of aluminum alloys.

Casting magnesium alloy has the characteristics of high specific strength, high specific stiffness, large vibration damping ability, stable performance of gasoline, kerosene and lubricating oil. These characteristics make magnesium alloys have a wide range of application prospects, such as transportation, electronic industry, military industry and so on. Especially in aerospace, rail transit, electronic products, biomedicine, bicycles, architectural decoration and other fields, it has broad application prospects and has become one of the development directions of new materials in the future.

Advantages of CNC Machining for Magnesium Alloys

1. Precision and Consistency

Computer Numerical Control (CNC) machining is a cutting-edge technology that offers unparalleled precision and consistency. The advanced software and automated processes ensure that every component is manufactured to exact specifications, reducing material waste and improving overall efficiency.

2. Complex Geometries

Magnesium alloys often find applications in parts with intricate designs and complex geometries. CNC machining excels in creating these intricate features with utmost precision, meeting the most demanding requirements of modern engineering projects.

3. Faster Turnaround Times

The streamlined nature of CNC machining drastically reduces production times compared to traditional methods. Rapid prototyping and shorter lead times enable businesses to bring their products to market faster, gaining a competitive edge in their industry.

4. Cost-Effectiveness

Although initial setup costs for CNC machines can be higher, the long-term cost-effectiveness is undeniable. Lower labor costs, minimal material wastage, and reduced rework contribute to substantial savings in the long run.

CNC Machining Methods for Magnesium Alloys

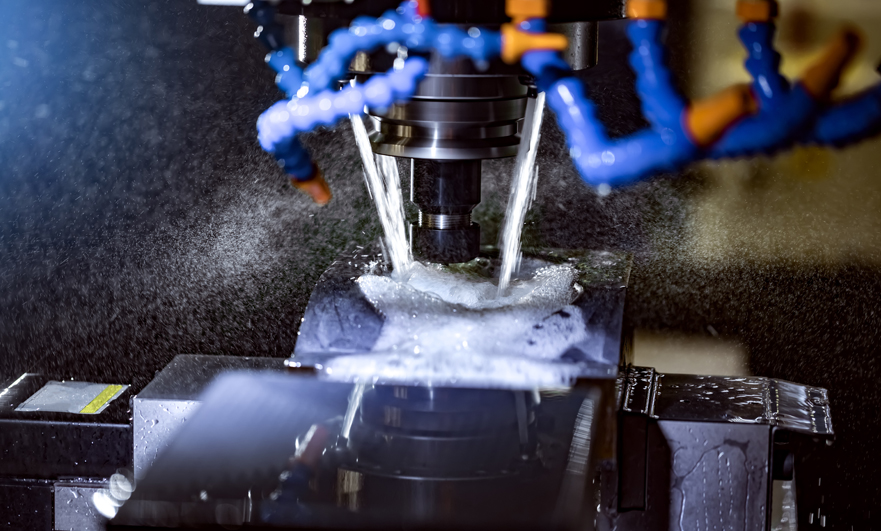

1. CNC Milling

CNC Milling is one of the most common CNC machining methods used for magnesium alloys. During the milling process, rotary cutting tools remove material from a workpiece to create the desired shape. This method is highly versatile and suitable for both simple and complex geometries.

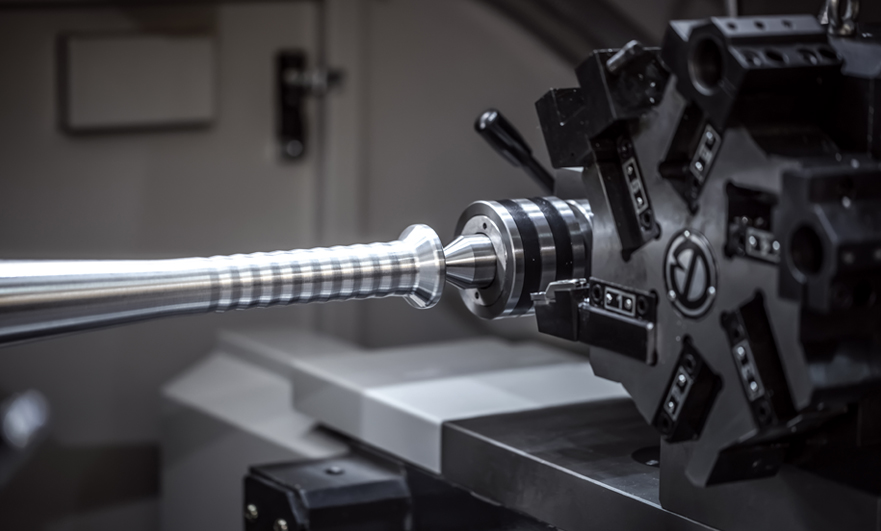

2. CNC Turning

CNC turning involves securing the magnesium alloy workpiece in a chuck and rotating it against cutting tools. This method is ideal for creating cylindrical or conical shapes, such as shafts, pins, and threaded components.

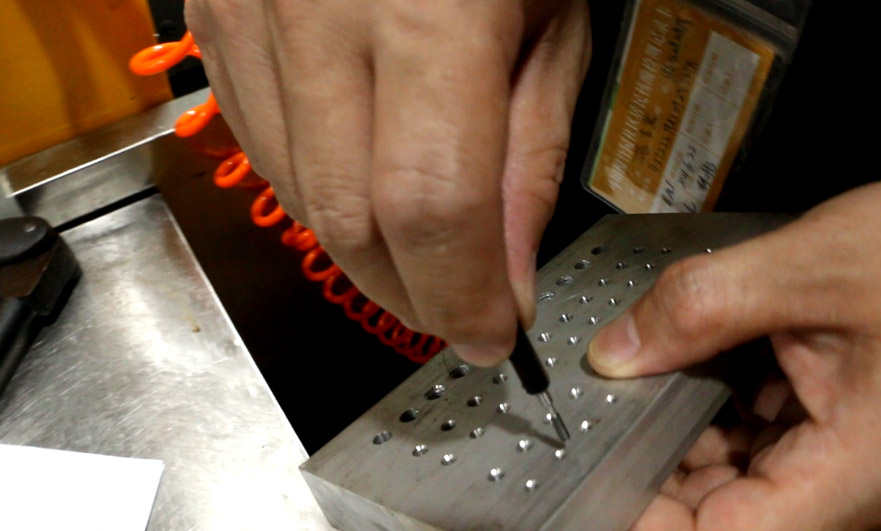

3. CNC Drilling

Drilling is a CNC machining process that creates holes in the magnesium alloy workpiece using rotary cutting tools. Precise drilling is crucial for many applications, and CNC machines deliver the accuracy required for intricate hole patterns.

4. Laser Cutting

Laser cutting utilizes high-powered lasers to cut through magnesium alloy sheets or plates with exceptional precision. This method is particularly effective for producing thin and intricate components in a swift and efficient manner.

5. Tapping

Tapping is employed to create internal threads in magnesium alloy parts. With CNC machining, the tapping process is automated, ensuring accurate thread dimensions and pitch.

6. Profiling

Profiling involves cutting the outline or shape of a component using a specialized tool. This technique is commonly used to create complex 2D and 3D shapes on magnesium alloy parts.

Tool Selection for Magnesium Alloy CNC Machining

For magnesium CNC machining, it is best to use a high speed tool or a carbide tipped tool. It is important to keep the tool sharp to avoid excessive heat. The experience with diamond tools is good, but the cost is relatively high. It is necessary to store mechanical products in dry conditions and additional protection is required when there is a chance of condensation. Machines should be kept clean and turntables should be stored in steel boxes.

Choosing the right tools for magnesium alloy CNC machining is crucial for achieving optimal results. Consider the following factors when selecting tools:

Material Compatibility: Ensure the tools are specifically designed for machining magnesium alloys to minimize tool wear and maximize efficiency.

Cutting Speed and Feed Rate: Select appropriate cutting speeds and feed rates to maintain tool life while achieving the desired machining results.

Tool Coatings: Consider using coatings like titanium nitride (TiN) or aluminum titanium nitride (AlTiN) to enhance tool life and reduce friction.

Cooling and Lubrication

Magnesium CNC machining is usually carried out without any coolant. If it is necessary to use a coolant, a light mineral oil will suffice. Do not use water-based coolants due to the risk of any reaction with the chips during storage.

Magnesium alloy CNC machining generates heat, and effective cooling and lubrication are essential to prevent overheating and tool damage. Cooling methods include flood cooling, mist cooling, and through-tool cooling. Lubrication with suitable coolants or cutting fluids helps reduce friction, prolong tool life, and improve surface finish.

Precautions for Magnesium Alloy CNC Machining

1. Fire and Explosion Hazards

Magnesium alloys are highly flammable, and the machining process can generate fine particles and shavings that are susceptible to ignition. Implementing proper ventilation, using suitable cutting fluids, and investing in fire-resistant enclosures are essential safety measures.

Magnesium powder is easy to burn and can cause an explosion when suspended in the air. All possible measures should be taken to ensure proper collection and disposal of magnesium powder.

During dry grinding of magnesium alloy parts, magnesium slag must be removed from the work area immediately with a well-designed wet vacuum system. The connection between the vacuum cleaner and the grinder should be short and straight, the vacuum cleaner should be kept clean, and the exhaust should be placed outside. Magnesium slag in the vacuum cleaner should be cleaned in time to prevent excessive accumulation. Magnesium slag should be stored in water before treatment.

Keeping the working environment clean and tidy at all times is the key to ensuring safe grinding of magnesium alloy parts. The connecting pipes between the grinding wheel and the vacuum cleaner must be checked and cleaned at least once a day, and the entire vacuum system must be thoroughly cleaned at least once a month. Do not allow magnesium dust to collect on seats, windows, pipes and other horizontal surfaces.

Magnesium products are not easy to ignite. Magnesium must be heated to its melting point, which is nearly impossible during normal CNC machining. Chips can ignite, but precautions should avoid this risk.

Magnesium dust appears to be so little, yet is highly flammable, and these precautions are necessary to minimize these risks:

Dry process or use light mineral oil

keep knives sharp

Chips are sent periodically and stored in a steel closed container.

Make sure you have the right fire extinguisher available

High-speed automatic CNC machining with compressed air during chip production

In the event of a fire, the dry spin will burn slowly and evenly. Do not quench magnesium with water, as burning magnesium will break down water to form hydrogen that ignites easily.

Potassium chloride fire extinguishing agent is the best fire extinguisher, other common fire extinguishers such as cast iron swing and dry sand.

Influence of Magnesium Alloys on Machinability

Impact on chip formation

The type of tip formed during CNC machining is related to material composition, part shape, alloy condition and feed rate. When single-edged tools are used in magnesium alloy turning, boring, planing and milling, the chips produced can be divided into three categories.

At higher feed ratios, coarse chips with good fracture are formed.

At moderate feed rates, chips of short length and good chip breaking are formed.

Long bending chips are formed at low feed rates.

Effect on Distortion

Magnesium has high specific heat and good thermal conductivity, the heat generated by friction quickly diffuses to various parts of the part, and magnesium alloys are not exposed to high temperatures during the cutting process. However, at high cutting speeds and high feeds, the heat generated by the part is also high, which can deform due to excessive temperature.

Effect on Thermal Expansion

If the dimensional tolerance of the finished product is strict, the factors affecting the thermal expansion coefficient of magnesium should be considered in the design. If a large amount of heat is generated under the above CNC machining conditions, it may affect the CNC machining accuracy of the part. The thermal expansion coefficient of magnesium is slightly higher than that of aluminum and significantly higher than that of steel. 26.6~27.4 μm/m°C in the range of 200°C.

Effect on cold deformation

During CNC machining, magnesium alloy parts are rarely deformed or deformed by cold deformation. However, if the tool becomes too blunt, it will slow down the feed rate, causing distortion and warping if the tool stalls during CNC machining.

Selecting the appropriate cutting tools for machining magnesium alloys is crucial. Tools with high-speed steel or carbide tips are commonly used, as they can withstand the heat and wear associated with machining these alloys effectively.

3. Machine Maintenance

Regular maintenance of CNC machines is vital to ensure optimal performance and accuracy. Proper cleaning, lubrication, and calibration of the machine components contribute to extending its lifespan and maintaining consistent results.

4. Material Handling

Due to its lightweight nature, magnesium alloy components can be sensitive to improper handling, leading to surface damage or deformation. Implementing appropriate material handling procedures and tools helps safeguard the integrity of the workpiece.

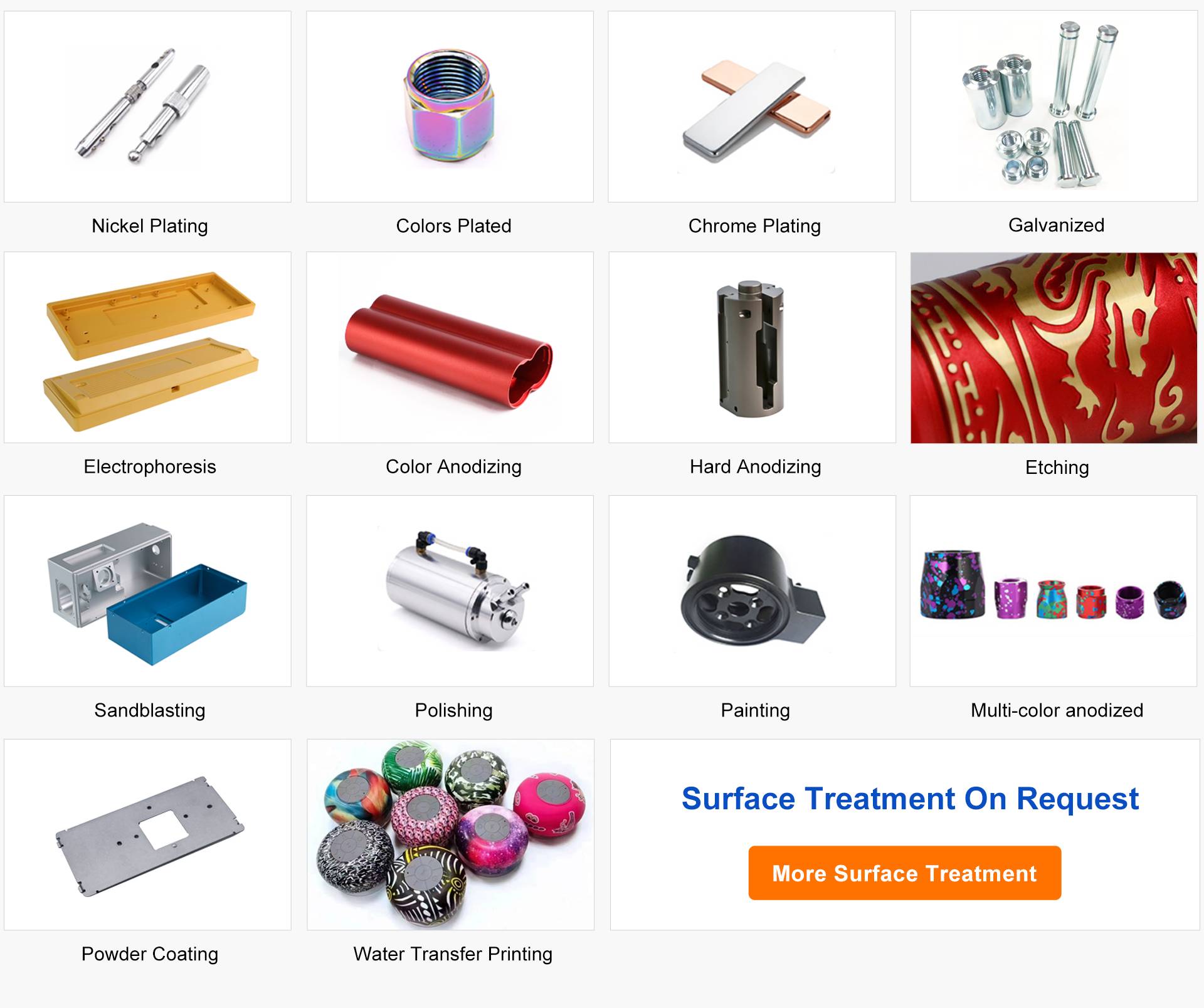

Surface Treatment for Magnesium Alloy Parts

Surface treatment processes can enhance the performance and aesthetics of magnesium alloy parts. Some common surface treatments include anodizing, chromate conversion coating, painting, and powder coating. These treatments provide corrosion resistance, improve wear resistance, and allow for customized colors and finishes.

Quality Control and Inspection

Quality control is vital in magnesium alloy CNC machining to ensure the production of accurate and reliable parts. Implement thorough inspection processes, including dimensional checks, surface finish evaluation, and material testing. Advanced metrology techniques such as coordinate measuring machines (CMM) and non-destructive testing (NDT) methods can be employed for precise quality control.

Applications of Magnesium Alloy CNC Machining

Magnesium alloy CNC machining finds applications across various industries, including:

Aerospace and Aviation: Magnesium alloy components for aircraft structures, engine parts, and lightweight panels.

Automotive: Transmission cases, engine components, suspension parts, and lightweight body frames.

Electronics: Lightweight casings for laptops, tablets, and smartphones.

Medical: Orthopedic implants, surgical instruments, and medical device components.

Conclusion

In conclusion, Magnesium Alloy CNC machining offers a plethora of advantages, ranging from precision and cost-effectiveness to faster turnaround times and intricate geometries. Understanding the various CNC machining methods, such as milling, turning, drilling, and laser cutting, allows manufacturers to leverage the full potential of magnesium alloys in their applications.

However, it is crucial to recognize the inherent hazards of machining magnesium alloys, particularly their flammability. By adhering to proper safety precautions, selecting the right cutting tools, and maintaining CNC machines diligently, manufacturers can achieve exceptional results while ensuring the safety of their workforce and facilities.

FAQs (Frequently Asked Questions)

1. Can magnesium alloys be used for structural applications?

Yes, magnesium alloys are widely used for structural applications in industries such as aerospace and automotive due to their excellent strength-to-weight ratio.

2. Are there any safety concerns associated with machining magnesium alloys?

Yes, magnesium alloys are flammable, so it is essential to follow proper safety protocols, including fire prevention measures and the use of personal protective equipment (PPE).

3. Can magnesium alloy parts be coated or painted?

Yes, magnesium alloy parts can undergo various surface treatments, including coating and painting, to enhance their performance and aesthetics.

4. What are the advantages of using CNC machining for magnesium alloys?

CNC machining offers precise and efficient production processes, complex shape creation, reduced material waste, high production speeds, and enhanced surface finish quality.

5. What industries benefit from magnesium alloy CNC machining?

Aerospace, automotive, electronics, and medical industries are among the key beneficiaries of magnesium alloy CNC machining.